Thin film transistor and display array substrate using same

A technology of thin film transistor and organic barrier layer, applied in transistors, electro-solid devices, semiconductor devices, etc., can solve the problems of frequency characteristics, inability to meet panel requirements, etc., and achieve the effect of improving TFT performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

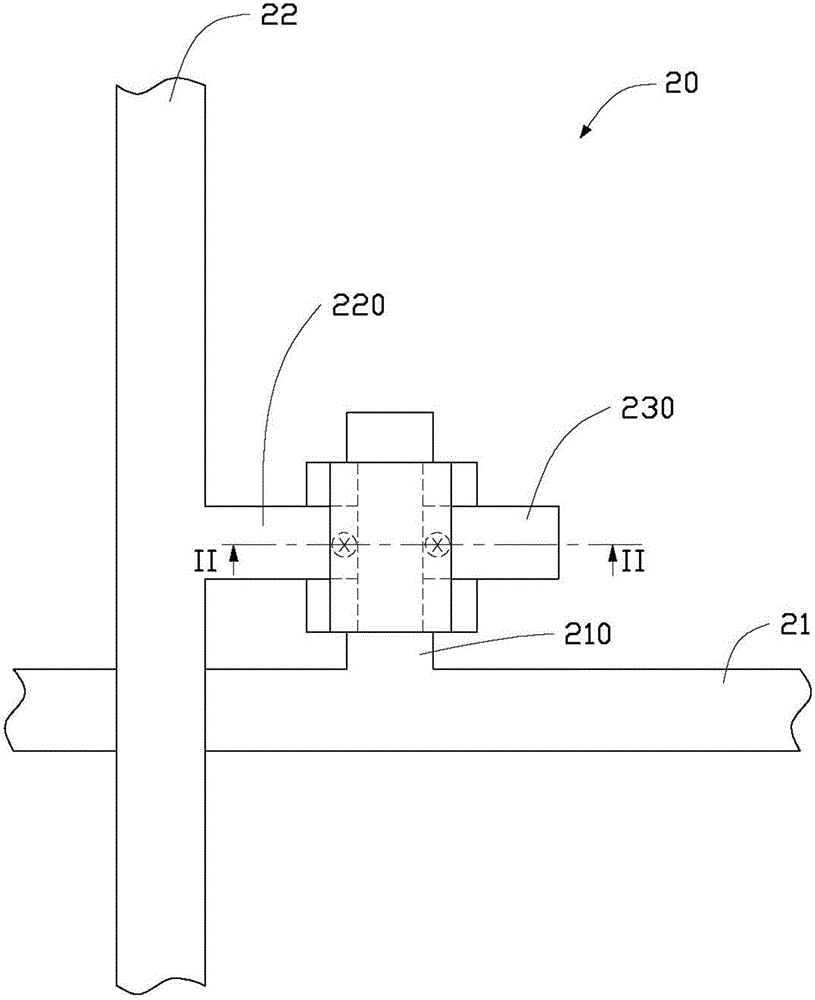

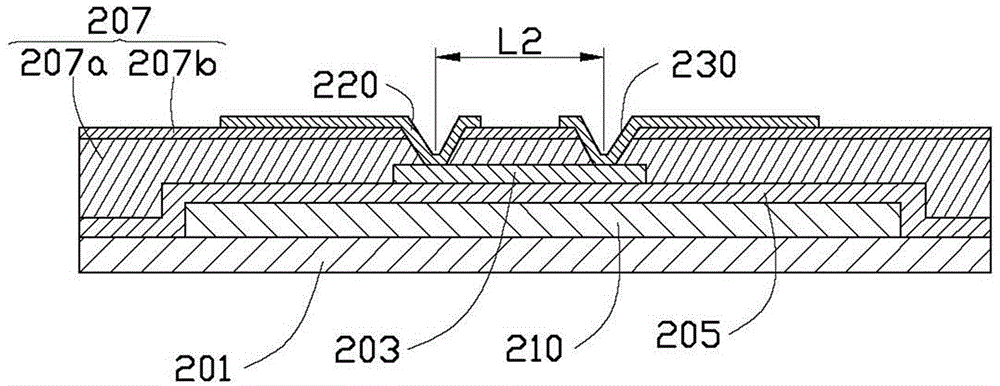

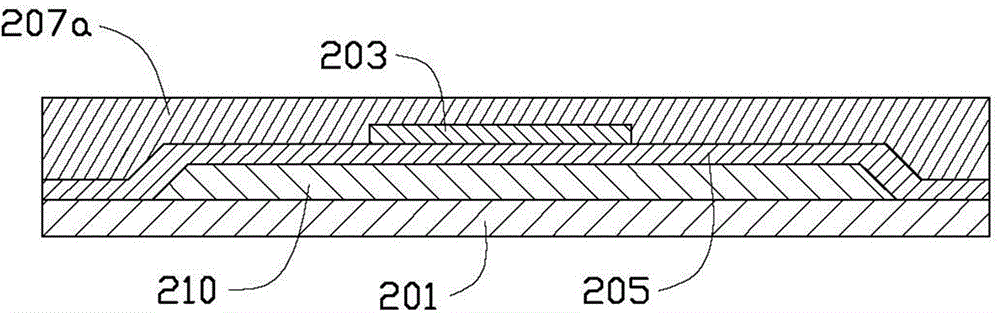

[0021] see figure 1 , figure 1 It is a schematic plan view of a part of a pixel area of a display array substrate according to an embodiment of the present invention. The display array substrate 20 includes a plurality of gate lines 21 parallel to each other, and a plurality of data lines 22 parallel to each other and insulated from and crossing the gate lines. A thin-film transistor (thin-film transistor, TFT) 200 is arranged at the intersection of each gate line 11 and a data line 12, and the thin-film transistor 200 includes a gate 210 connected to the gate line 21 for an external gate driver (not shown) shown), the source 220 connected to the data line 22 is used to receive the data signal output from an external data driver (not shown), and the drain 230 is spaced apart from the source 220 .

[0022] When the gate signal voltage output by the gate line 210 is higher than the threshold voltage of the thin film transistor 200, the channel layer 203 formed inside the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com