Preparation method and product of dairy product for strengthening medium-chain fatty acid

A medium-chain fatty acid, dairy product technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of mild milk flavor and weak taste, and achieve the effects of rich milk flavor, delicate and smooth taste, and uniform color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

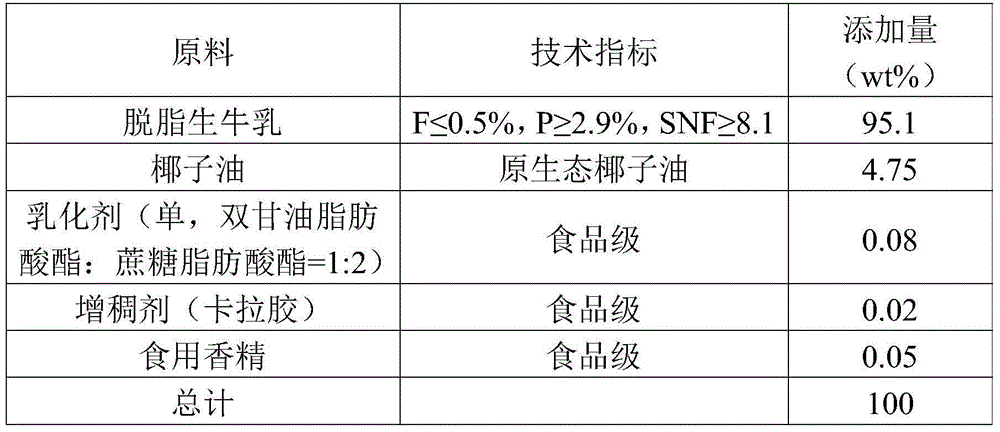

[0042] 1. Raw material formula (see Table 1).

[0043] The raw material formula of table 1 embodiment 1

[0044]

[0045] Among them, F stands for milk fat, P stands for protein, and SNF stands for milk solids not fat.

[0046] 2. Preparation method:

[0047] ① Calculate the water to be evaporated according to the added amount of each raw material, and concentrate the skim milk through falling film concentration;

[0048] ②Mix the concentrated skimmed milk, coconut oil, thickener and emulsifier (75°C, 10min);

[0049] ③ Grinding and refining the mixed solution;

[0050] ④ Perform immersion ultra-high temperature instantaneous (also known as Infusion UHT, referred to as immersion UHT) sterilization (135°C, 1s);

[0051] ⑤ Carry out aseptic homogenization of the sterilized feed liquid (the first-level homogenization pressure is 15MPa, the second-level homogenization pressure is 5MPa, and the temperature is 50°C);

[0052] ⑥ Cool (20°C), and aseptically fill.

[0053] The ...

Embodiment 2

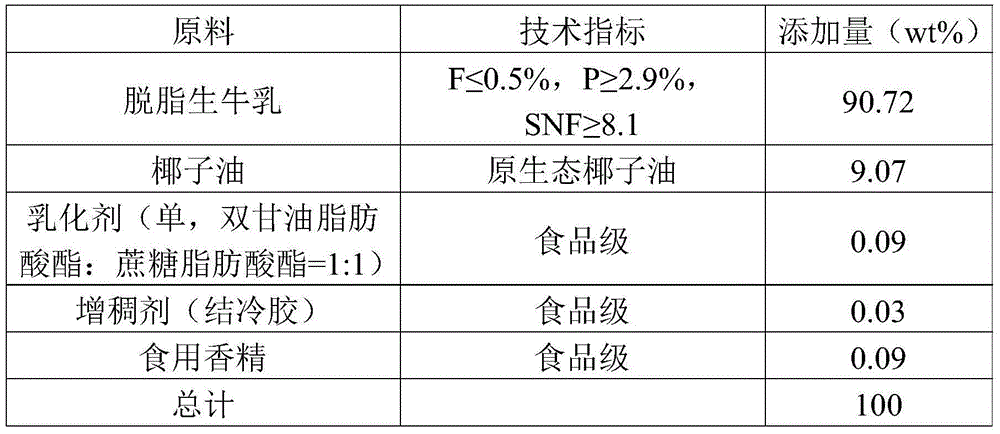

[0055] 1. Raw material formula (see Table 2).

[0056] The raw material formula of table 2 embodiment 2

[0057]

[0058] Among them, F stands for milk fat, P stands for protein, and SNF stands for milk solids not fat.

[0059] 2. Preparation method:

[0060] ① Calculate the water to be evaporated according to the added amount of each raw material, and concentrate the skim milk through falling film concentration;

[0061] ②Mix the concentrated skimmed milk, coconut oil, thickener and emulsifier (80°C, 20min);

[0062] ③ Grinding and refining the mixed solution;

[0063] ④ Perform immersion ultra-high temperature instantaneous (also known as Infusion UHT, referred to as immersion UHT) sterilization (140°C, 3s);

[0064] ⑤ Homogenize the sterilized feed liquid after aseptic (first grade 20MPa, second grade 10MPa, 70°C);

[0065] ⑥ Cool (30°C), and aseptically fill.

[0066] The dairy product has good flavor, color and taste, is stable and uniform, has no sedimentation a...

Embodiment 3

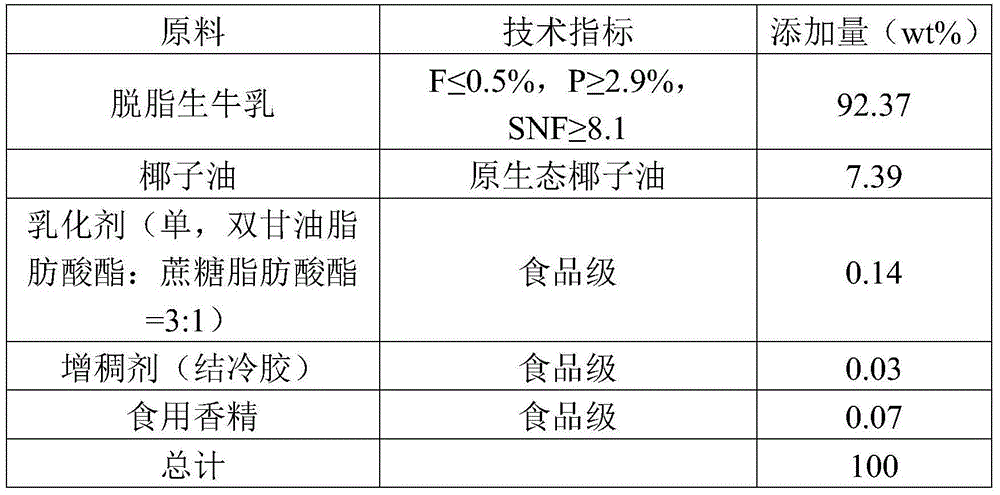

[0068] 1. Raw material formula (see Table 3). In the thickener, the mass ratio of gellan gum and carrageenan is (4): (1)

[0069] The raw material formula of table 3 embodiment 3

[0070]

[0071] Among them, F stands for milk fat, P stands for protein, and SNF stands for milk solids not fat.

[0072] 2. Preparation method:

[0073] ① Calculate the water to be evaporated according to the added amount of each raw material, and concentrate the skim milk through falling film concentration;

[0074] ②Mix the concentrated skim milk, coconut oil, thickener and emulsifier (80°C, 10min);

[0075] ③ Grinding and refining the mixed solution;

[0076] ④ Perform immersion ultra-high temperature instantaneous (also known as Infusion UHT, referred to as immersion UHT) sterilization (140°C, 1s);

[0077] ⑤ Homogenize the sterilized feed liquid after aseptic (first grade 20MPa, second grade 5MPa, 50°C);

[0078] ⑥ Cool (25°C), and aseptically fill.

[0079] The dairy product has goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com