Multilayer countercurrent rotating packed bed

A rotating packed bed, counter-flow technology, applied in the direction of fractionation, etc., can solve problems such as the limitation of gas-liquid mass transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

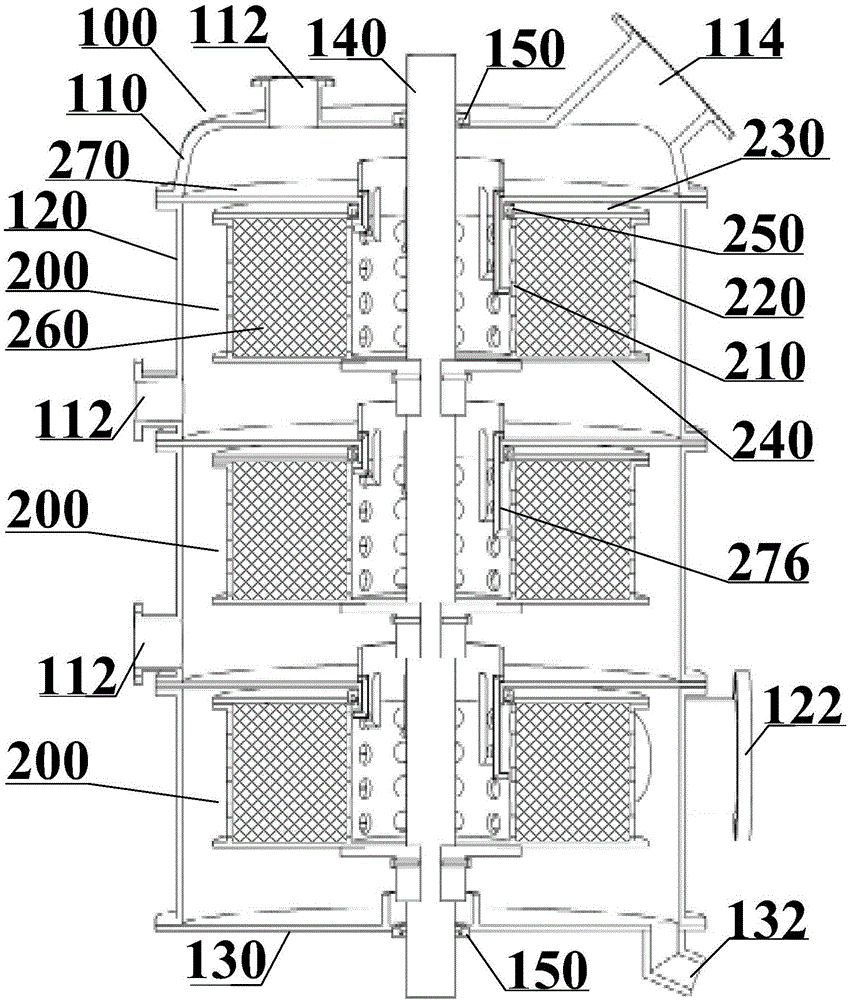

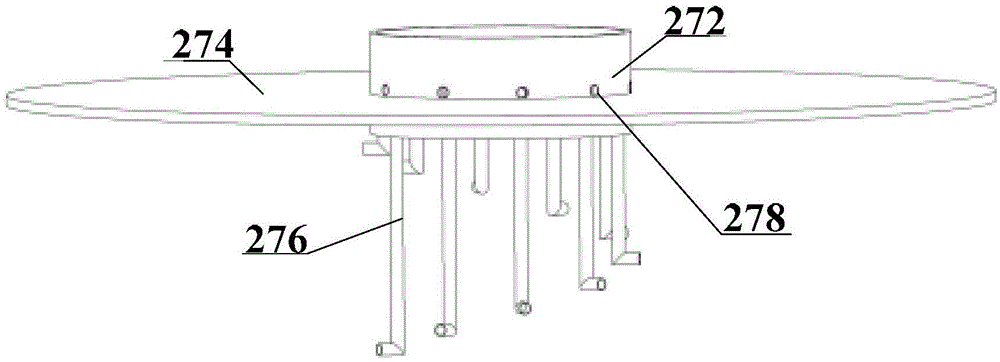

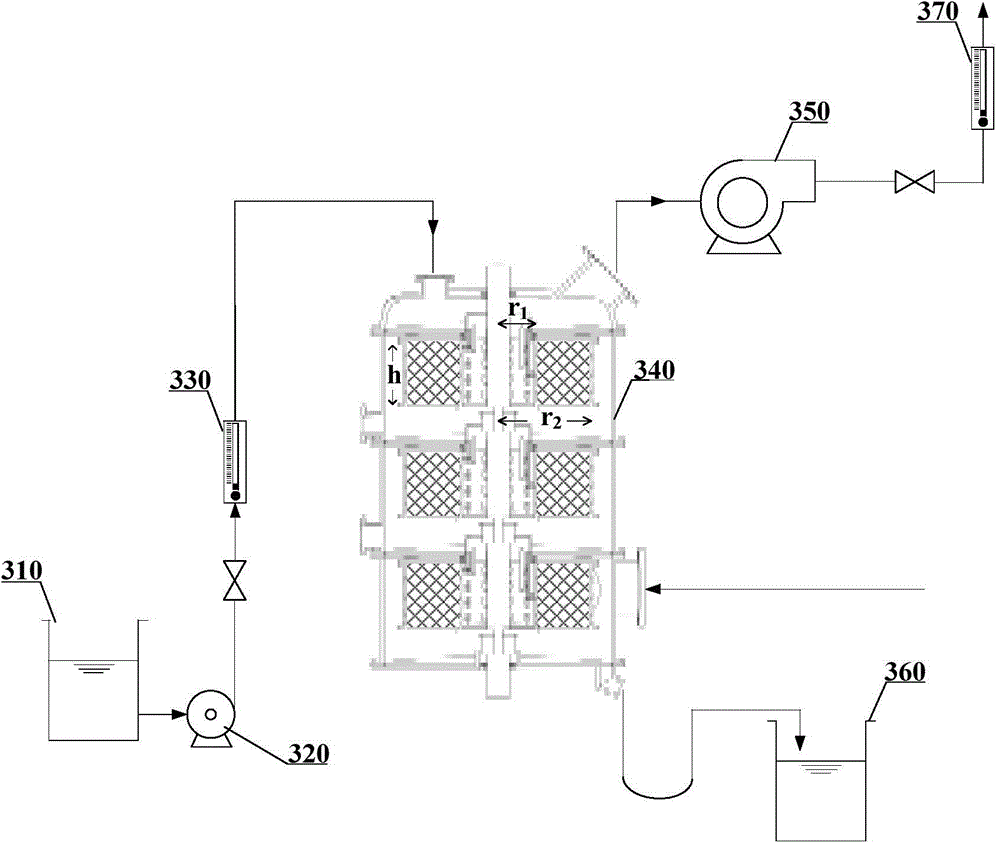

[0018] Use the present invention to carry out the test of ammonia nitrogen in the air stripping water of multi-layer (three layers) counter-current rotary packed bed, the solid filler in the bed is stainless steel wire mesh; Rotary packed bed inner diameter 240mm, outer diameter 580mm, each rotary packed bed 200 Axial height (h) 150mm. The average radius r of the rotating packed bed 200 can be calculated avg , as shown in formula (1):

[0019] r avg =2(r 1 2 + r 1 r 2 + r 2 2 ) / [3(r 1 + r 2 )] Formula (1)

[0020] Among them, r 1 with r 2 are the inner and outer radii of the rotating packed bed 200, respectively. The radial average cross-sectional area of a rotating packed bed can be calculated as 2πr avg h.

[0021] Superficial gas velocity = gas flow rate / average cross-sectional area; superficial liquid velocity = liquid flow rate / average cross-sectional area. The supergravity factor is defined as the ratio of the centrifugal acceleration of the rotating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com