Dehydration process for mixed ionic liquid

An ionic liquid and hybrid technology, which is applied in the direction of solid adsorbent liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of low water removal efficiency of ionic liquids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

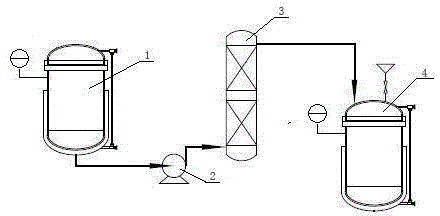

[0020] as attached figure 1 Shown, the present invention uses rectifying tower 3 dry mass ratios to be 1-methyl-2-allyl-3-methylimidazole-bistrifluoromethylsulfonylimide salt and N-methyl -N-Propylpiperidine-mixture of bistrifluoromethylsulfonimide salts. The rectification tower 3 is filled with a solid water-removing filler mixture, wherein the solid water-removing filler mixture is a mixture of alumina, activated carbon and adsorption material NSUL-1 in a mass ratio of 3:1:1. Pass the ionic liquid in the raw material liquid storage tank 1 into the rectification tower 3, keep the pressure of the rectification tower 3 at 1.0 MPa, feed water vapor or heat transfer oil into the jacket layer of the rectification tower 3, and keep the temperature of the tower body At 80° C.; the ionic liquid enters from the bottom of the rectification tower and exits from the top of the tower. When it is detected that the water content of the ionic liquid is less than or equal to 20 ppm, the drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com