Method for preparing zinc tungstate-cadmium sulfide heterojunction photocatalyst

A photocatalyst, zinc tungstate technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problems of photocorrosion, low separation efficiency, limited wide application, etc. Simple method, good hydrogen production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

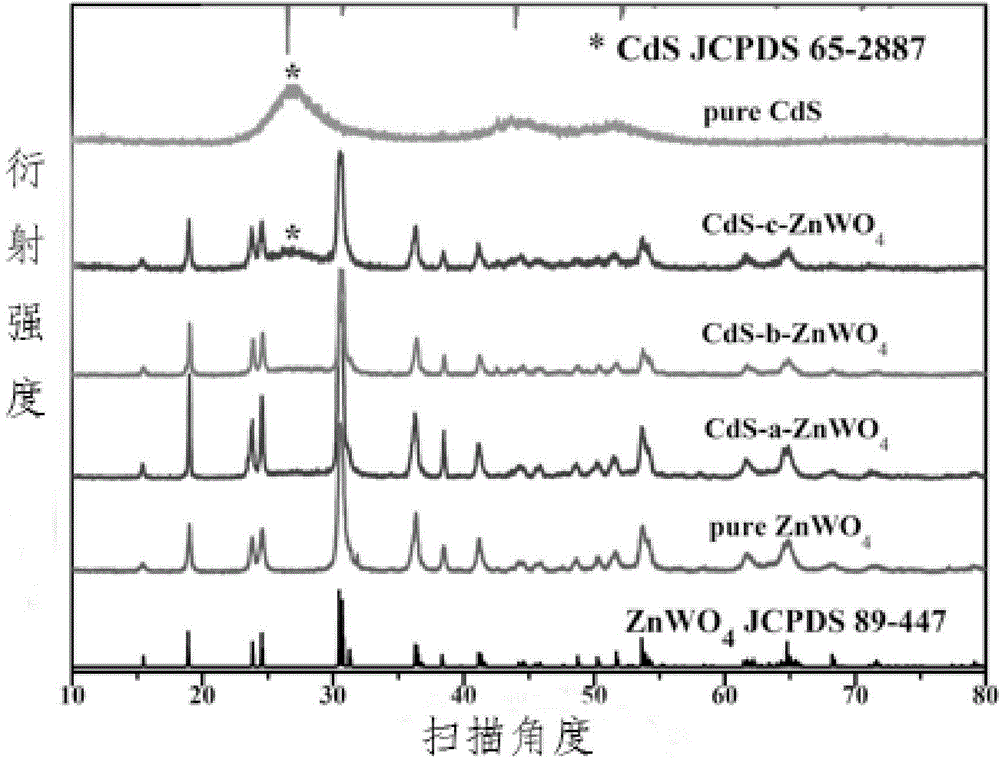

[0025] A method for preparing zinc tungstate-cadmium sulfide heterojunction photocatalyst, adopts the following steps:

[0026] (1) In a beaker, prepare 20 ml of chromium nitrate solution of 0.1 mole per liter with deionized water and analytically pure chromium nitrate, and add 0.023 grams of prefabricated zinc tungstate nanorods to the prepared .1 mole per liter of chromium nitrate solution. The zinc tungstate nanorods were completely dispersed in the solution by ultrasonication.

[0027] (2) prepare 0.1 moles of sodium sulfide solution per liter, pipette 0.05 milliliters of 0.1 moles of sodium sulfide solution per liter with a pipette, and add dropwise to the dispersion system in (1) with a dropper, and stir under magnetic force Keep stirring at room temperature for 2 hours, filter the precipitate, wash it several times with deionized water, and then dry it in vacuum at 60°C to obtain CdS-ZnWO 4 Heterojunction.

[0028] (3) Using a mixed solution of 0.35 mol per liter of ...

Embodiment 2

[0031] Step is the same as Example 1, except that the sodium sulfide solution added in Example 1 of 0.1 moles per liter is changed to 0.5 milliliters.

[0032] The resulting CdS-ZnWO 4 The heterojunction is labeled as CdS-b-ZnWO 4 . The photohydrogen production efficiency of the material is 629.2 micromol / hour (0.02 g catalyst).

Embodiment 3

[0034] Step is the same as Example 1, except that the sodium sulfide solution added in Example 1 of 0.1 mole per liter is changed to 1ml.

[0035] The resulting CdS-ZnWO 4 The heterojunction is labeled as CdS-c-ZnWO 4 . The photohydrogen production efficiency of the material is 692 micromole / hour (0.02 g catalyst).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com