CNC engraving and milling machine for precision machining

A technology of precision machining, engraving and milling machine, applied in the direction of metal processing mechanical parts, metal processing equipment, milling machine, etc., can solve the problems of low machining accuracy and product forming efficiency, weak bearing capacity of engraving and milling machine, etc., to improve the smooth operation, Good balance and low friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

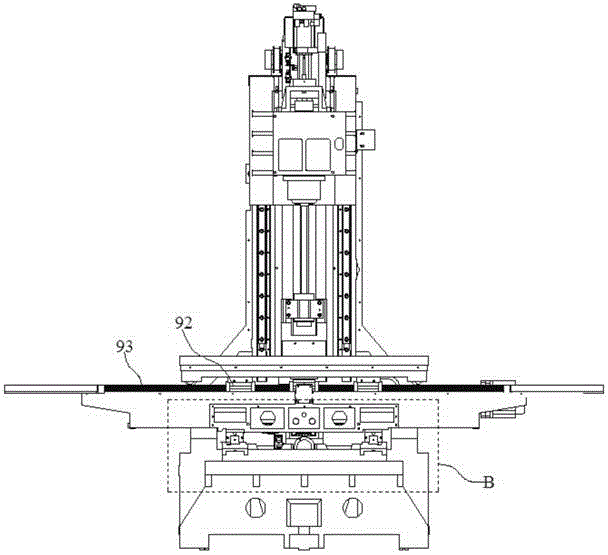

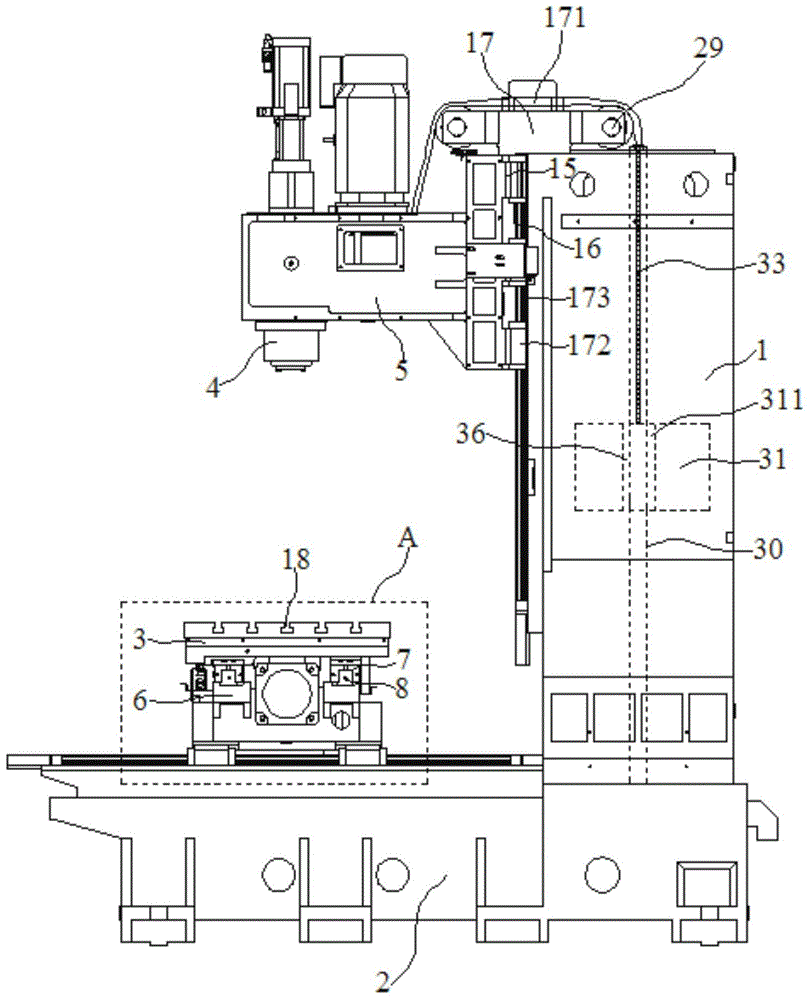

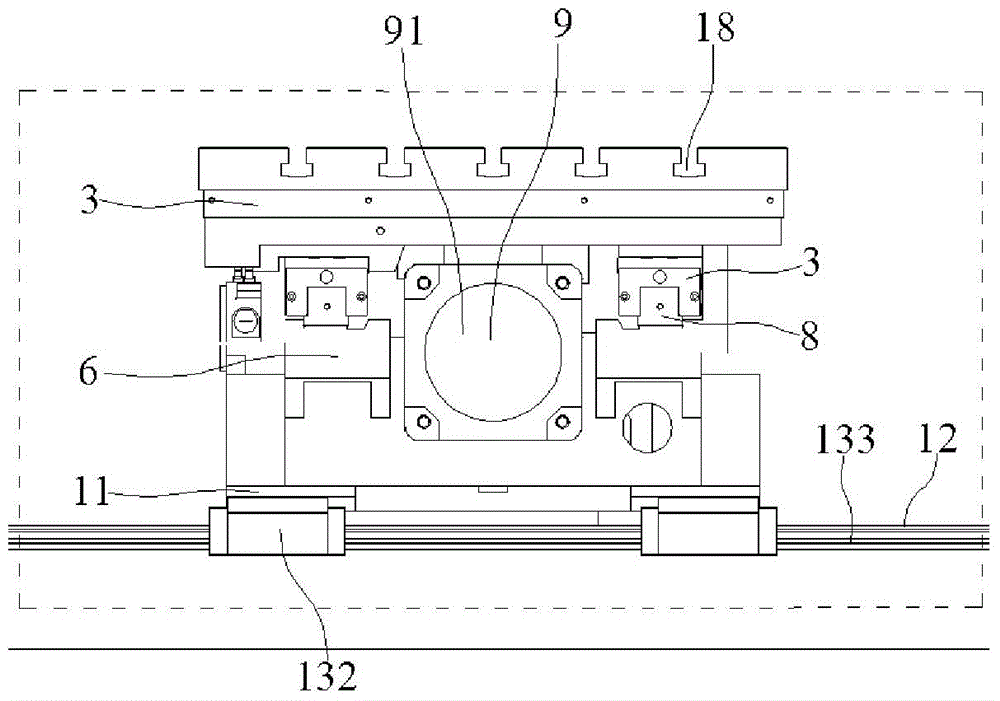

[0032] Embodiment: A CNC engraving and milling machine for precision machining, including a column 1, a base 2, a worktable 3, a machine head 5 with a cutter 4, a first steel ring sleeve 19, a second steel steel ring sleeve 20, and a third The steel ring sleeve 26, the fourth steel ring sleeve 27 and the support plate 6 between the base 2 and the workbench 3, the column 1 is fixed on the upper surface of the base 2, and the machine head 5 is located on the upper side of the column 1 And above the workbench 3;

[0033] The column 1 includes a column 101, a first support leg 102 and a second support leg 103 respectively fixed on both sides of the lower end surface of the column 101, the first support leg 102 and the second support leg 103 are respectively fixed to the base 2 On both sides of the upper surface, a hollow area is formed between the first supporting leg 102, the second supporting leg 103, the base 2 and the column 101;

[0034] At least two x-direction sliders 7 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com