A kind of polyether ether ketone thin tube extrusion production process and device

A polyether ether ketone thin tube and production process technology, which is applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of product quality decline, product stress, and melt viscosity, etc., and achieve the elimination of internal stress and traction Appropriate speed and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

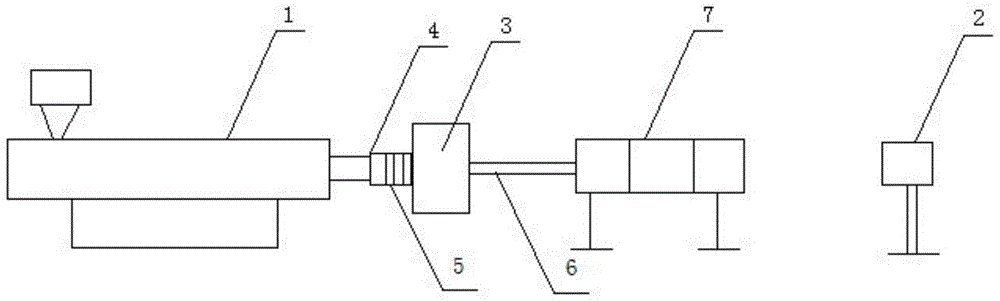

[0025] See figure 1

[0026] The first step, raw material drying

[0027] Dry in a circulating air oven at 150°C for 4 hours. During the drying process, dust and impurities should be prevented from mixing into it, which will cause bad defects such as black spots on the product.

[0028] The second step, feeding process

[0029] The feeding meter is used for feeding to ensure that the hopper is not empty during the extrusion process to prevent air from entering, resulting in oxidation and air bubbles in the finished product. Materials of different grades cannot be mixed to prevent sundries and miscellaneous materials from entering and blocking the feeding port.

[0030] The third step, extrusion process

[0031] A 35mm single-screw extruder is used, and the barrel is divided into three sections for heating. The temperature of the feeding section is 345°C, the compression section is 365°C, the homogenization section is 375°C, the temperature of the head part is 380°C, and th...

Embodiment 2)

[0042] See figure 1

[0043] The first step, raw material drying

[0044] Dry in a circulating air oven at 150°C for 4.5 hours. During the drying process, dust and impurities should be prevented from mixing into it, which will cause bad defects such as black spots on the product.

[0045] The second step, feeding process

[0046] The feeding meter is used for feeding to ensure that the hopper is not empty during the extrusion process to prevent air from entering, resulting in oxidation and air bubbles in the finished product. Materials of different grades cannot be mixed to prevent sundries and miscellaneous materials from entering and blocking the feeding port.

[0047] The third step, extrusion process

[0048] A 35mm single-screw extruder is used, and the barrel is divided into three sections for heating. The temperature of the feeding section is 350°C, the compression section is 370°C, the homogenization section is 375°C, the temperature of the head part is 380°C, and ...

Embodiment 3)

[0061] See figure 1

[0062] The first step, raw material drying

[0063] Dry in a circulating air oven at 150°C for 5 hours. During the drying process, dust and impurities should be prevented from mixing into it, which will cause bad defects such as black spots on the product.

[0064] The second step, feeding process

[0065] The feeding meter is used for feeding to ensure that the hopper is not empty during the extrusion process to prevent air from entering, resulting in oxidation and air bubbles in the finished product. Materials of different grades cannot be mixed to prevent sundries and miscellaneous materials from entering and blocking the feeding port.

[0066] The third step, extrusion process

[0067] A 35mm single-screw extruder is used, and the barrel is divided into three sections for heating. The temperature of the feeding section is 355°C, the compression section is 375°C, the homogenization section is 385°C, the temperature of the head part is 380°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com