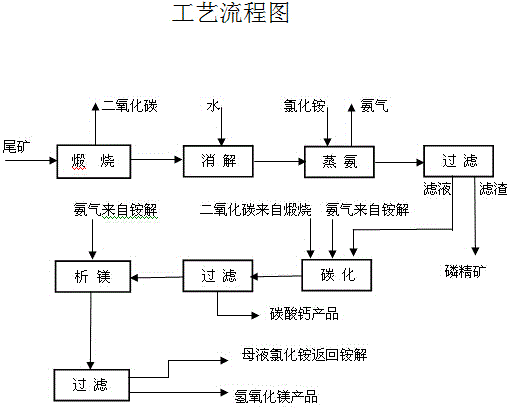

Method of preparing magnesium hydroxide and calcium carbonate and separating out phosphorus ores by taking phosphate tailings as raw materials through ammonia circulation process

A technology of magnesium hydroxide and phosphorus tailings, which is applied in the processing of magnesium hydroxide, calcium carbonate/strontium/barium, phosphate materials, etc., can solve the problems of waste of resources, low utilization value, and low content of P2O5.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1: Take 100 grams of phosphorus tailings, calcined at 1000°C for 1.5 hours, add 500ml of water to digest, then add 90g of ammonium chloride, heat to boiling, after ammonia distillation is complete, wait for cold filtration to obtain filter residue which is phosphorus concentrate. Add 20 g of ammonium carbonate to 400 ml of the filtrate, precipitate and filter to obtain 25 g of calcium carbonate, then add ammonia water to the filtrate, filter after precipitation to obtain 10 g of magnesium hydroxide, and continue to recycle the mother liquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com