Preparation method for mesoporous multi-element metal oxide

A multi-metal and oxide technology, applied in the field of mesoporous materials, can solve the problem of high price of surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 A kind of mesoporous multi-element metal oxide BaTiO 3 preparation method

[0039] 1) Dissolve 0.02mol tetrabutyl titanate in ethanol, and dissolve 0.03mol BaCO 3 Dissolve in acetic acid solution, mix the two solutions to get mixed solution E;

[0040] 2) Add surfactant P123 to mixed solution E, stir evenly to obtain solution F;

[0041] 3) Evaporate solution F to dryness in an oven at 40°C for 24 hours to obtain a solid mixture;

[0042] 4) roasting the solid mixture at a temperature of 550° C. for 3 hours;

[0043] 5) The roasted samples were treated with HNO 3 Treatment to remove excess BaCO 3 , to obtain the target product mesoporous multi-metal oxide BaTiO3 , named MBT-1.5.

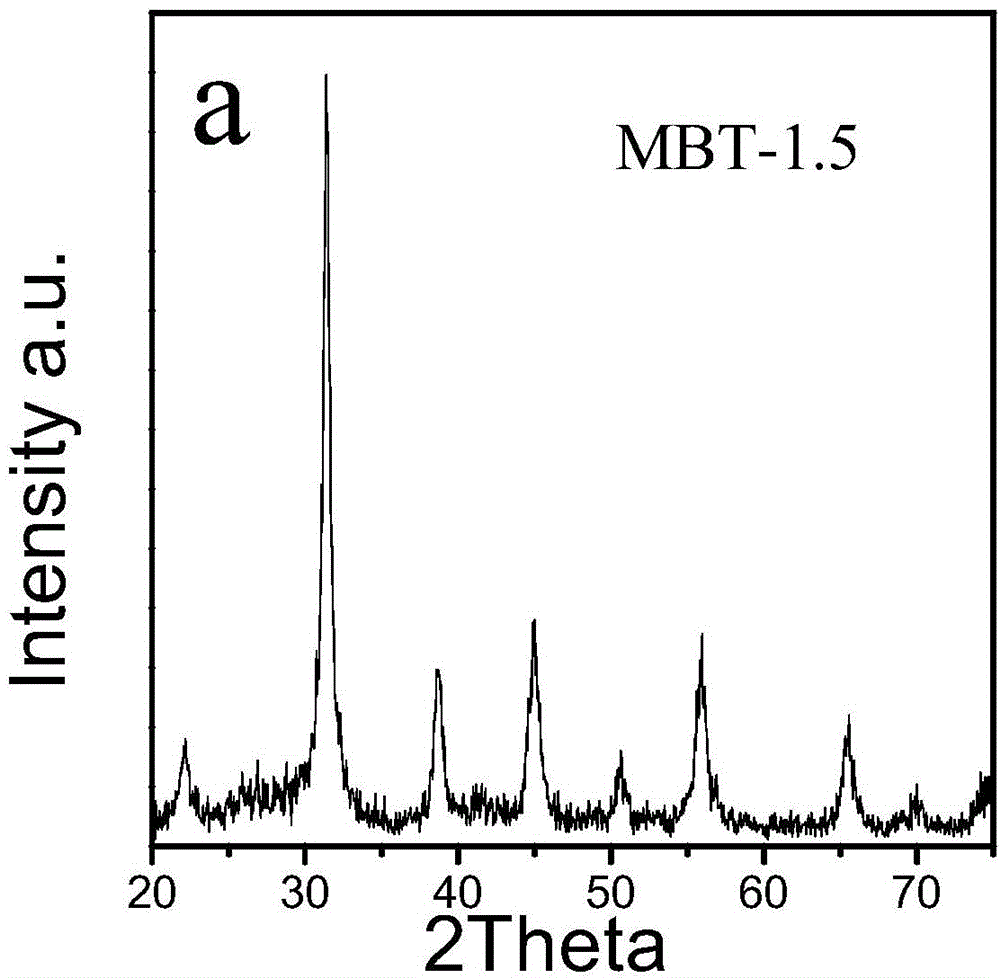

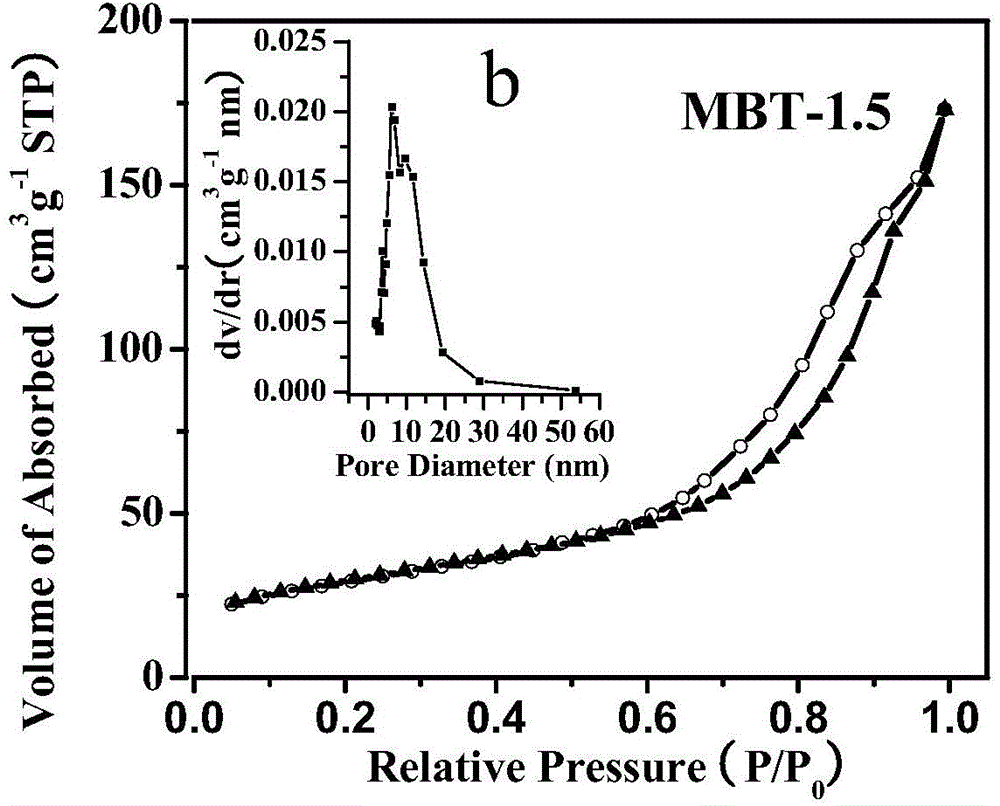

[0044] MBT-1.5 was tested by X-ray diffraction and nitrogen absorption and desorption, the results are as follows figure 1 and 2 as shown, figure 1 The diffraction peaks in all correspond to BaTiO 3 The characteristic diffraction peaks (JCPDS No.75-0213) are determined b...

Embodiment 2

[0045] Embodiment 2 A kind of mesoporous multi-element metal oxide SrTiO 3 preparation method

[0046] 1) 0.02mol tetrabutyl titanate was dissolved in ethanol, 0.04mol SrCO 3 Dissolve in acetic acid solution, mix the two solutions to get mixed solution E;

[0047] 2) Add 0.03 mol of citric acid as a surfactant into the mixed solution E, and stir evenly to obtain solution F;

[0048] 3) Evaporate solution F to dryness in an oven at 40°C for 24 hours to obtain a solid mixture;

[0049] 4) roasting the solid mixture at a temperature of 550° C. for 3 hours;

[0050] 5) The roasted samples were treated with HNO 3 Treatment to remove excess SrCO 3 , to obtain the target product mesoporous multi-metal oxide SrTiO 3 , named MST-2.

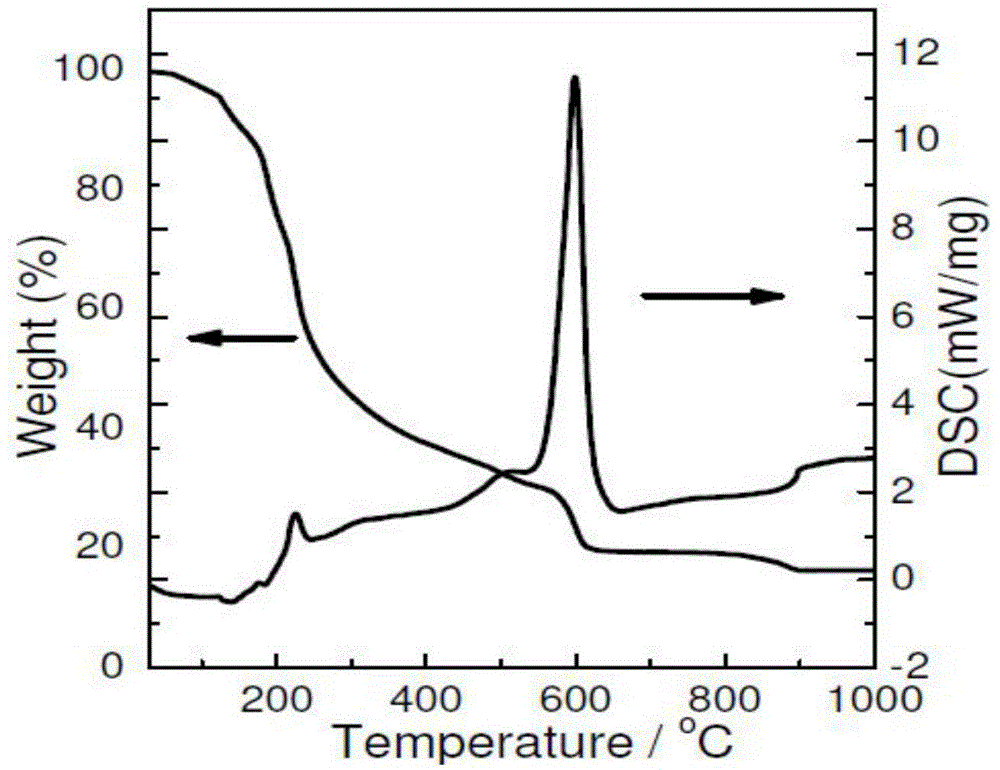

[0051] Carry out TG-DTA test to step 4) in solid mixture, result is as follows image 3 Shown is the weight loss and differential heat change of the sample during the heating and roasting process of the solid mixture in step 4), by image 3 It can...

Embodiment 3

[0055] Embodiment 3 A kind of mesoporous multi-element metal oxide SrTiO 3 preparation method

[0056] Method is the same as embodiment 2, just in step 1 with 0.02mol SrCO 3 Soluble in acetic acid solution.

[0057] Obtain the target product mesoporous multi-metal oxide SrTiO 3 , named MST-1.

[0058] The MST-1 was tested by nitrogen absorption and desorption, the results are as follows Figure 8 As shown in the figure, the adsorption and desorption curves of nitrogen in the figure do not overlap and there is a hysteresis loop, indicating that the synthesized MST-1 has a mesoporous structure, and the specific surface area of MST-1 is 46m 2 / g, far less than the MST-2 prepared in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com