Wastewater treating device and method

A waste water treatment and waste water technology, applied in water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of destroying the self-purification ability of natural water bodies, aggravating the problem of land salinization, and harsh water ecological environment impact and other issues, to achieve the effect of alleviating the shortage of water resources, reducing the adverse impact, weakening the effect of concentration polarization and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

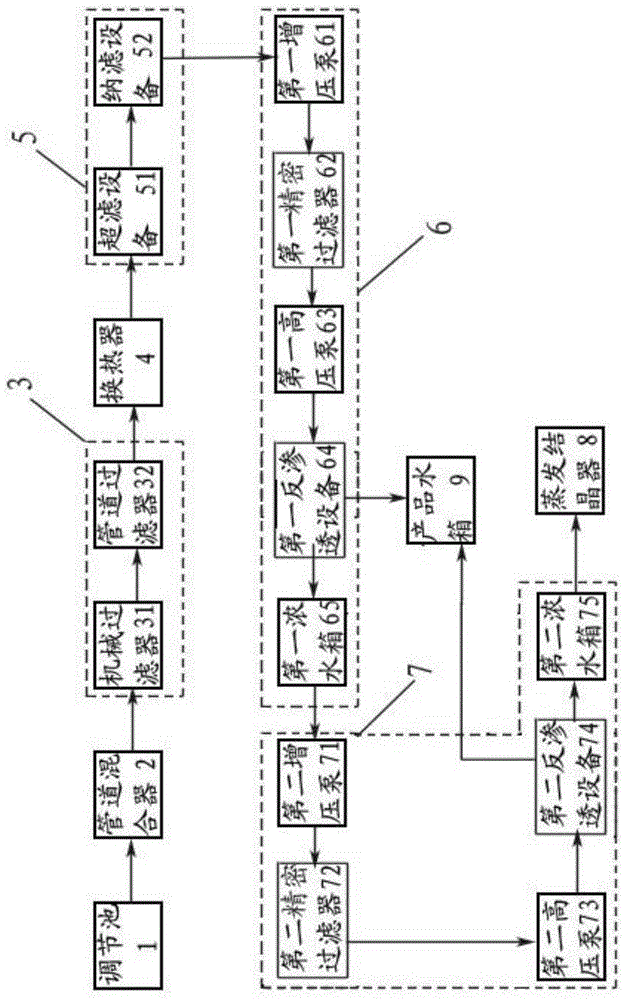

[0057] Such as figure 1 As shown, the flow rate of wastewater discharged by an enterprise is 200m 3 / h, the TDS of the wastewater is about 4000mg / L-5000mg / L, the turbidity is about 10-20NTU, and the COD value is about 150-200mg / L. The waste water is first introduced into the adjustment tank 1 for homogeneous and even quantity adjustment, and then sent to the pipeline mixer 2 to be fully mixed with the added aluminum salt flocculant to produce flocculation, forming large particle flocs, and then sent to the first-stage filtration system Filter in 3, filter through mechanical filter 31 in the first-stage filtration system 3, intercept more than 99% of large particle suspended matter and more than 80% of colloidal matter, the turbidity of the effluent is ≤5NTU, the COD value is about 150mg / L, and then through The line filter 32 further removes impurities. Wastewater treated by the primary filtration system 3 enters the heat exchanger 4 to adjust the temperature to 22°C to 25°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com