A continuous acidification process for synthesizing 2-naphthol

A technology, naphthol technology, applied in the field of continuous acidification process for the synthesis of 2-naphthol, can solve the problems of difficult control, prolonging the production cycle, high synthesis cost, etc., and achieve the goal of reducing waste water generation, improving utilization rate and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

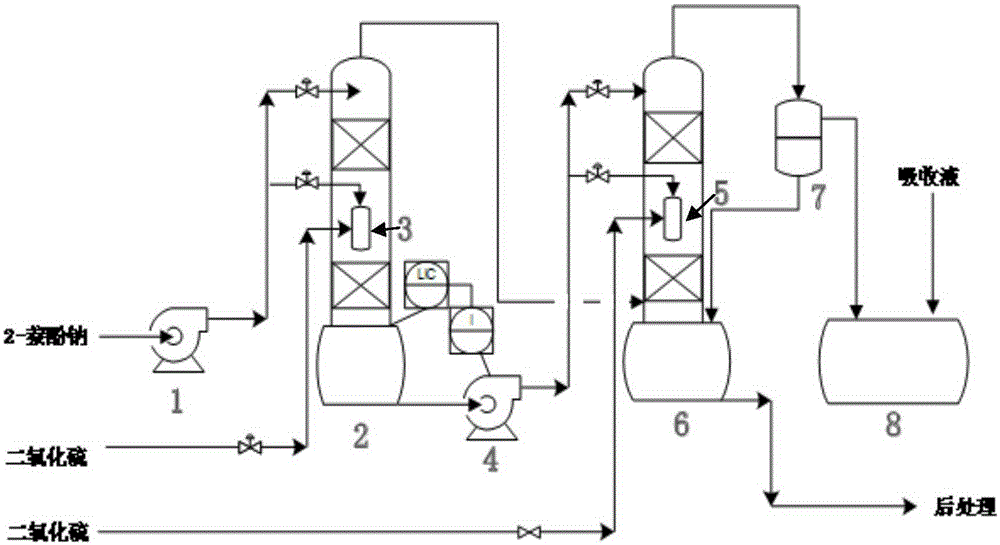

Image

Examples

Embodiment 1

[0037] Flow is that 3.338 tons / hour 2-naphthol sodium (mixture, 2-naphthol content is 20.6%) enters the first acidification tower by the first injection nozzle in the first acidification tower middle part, 13.352 tons / hour 2-naphthol sodium ( Mixture, 2-naphthol content is 20.6%) enters the first acidizing tower by tower top, and 1.134 tons / hour sulfur dioxide enters the first acidizing tower by the first injection head, 2-naphthol sodium and sulfur dioxide convective flow in the first tower Quality, and react, the reaction temperature is 78 ° C, the first acidification tower packing is stainless steel corrugated packing, the reaction generated 2-naphthol and unreacted 2-naphthol sodium mixture (ie liquid mixture A) enters the first acidification The tower still of tower, unreacted sulfur dioxide gas is discharged from the tower top of the first acidification tower;

[0038]The mixed material (i.e. liquid mixture A) flowing out of the bottom of the first acidification tower is...

Embodiment 2

[0040] Flow rate is that 3.338 tons / hour 2-naphthol sodium (mixture, 2-naphthol content is 20.6%) enters the first injection head in the first acidizing tower tower, and 13.352 tons / hour 2-naphthol sodium enters the first by tower top One acidification tower, 1.134 tons / hour sulfur dioxide enters the first acidification tower through the first injection head, 2-naphthate sodium and sulfur dioxide convect mass transfer in the first tower and react, the first acidification tower packing is ceramic saddle packing , the unreacted sulfur dioxide gas enters the bottom of the second tower from the top of the tower and reacts with the material in the second tower, and the 2-naphthol and unreacted sodium 2-naphthol mixed solution that the reaction generates enters the first acidification tower tower kettle, and reacts The temperature is 78°C;

[0041] The mixed material in the bottom of the first acidification tower is pumped to the top of the second acidification tower and into the to...

Embodiment 3

[0043] Flow rate is that 3.338 tons / hour 2-naphthol sodium (mixture, 2-naphthol content is 20.6%) enters the first injection head in the first acidizing tower tower, and 13.352 tons / hour 2-naphthol sodium enters the first by tower top One acidification tower, 1.134 tons / hour sulfur dioxide enters the first acidification tower through the first injection head, 2-naphthate sodium and sulfur dioxide convect mass transfer in the first tower and react, the first acidification tower packing is stainless steel corrugated packing, The unreacted sulfur dioxide gas enters the bottom of the second tower from the top of the tower to react with the material in the second tower, and the 2-naphthol and unreacted 2-naphthol sodium mixture that is generated by the reaction enters the first acidification tower tank, and the reaction temperature is 78°C;

[0044] The mixed material in the bottom of the first acidification tower is pumped to the top of the second acidification tower and into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com