Improved method of traditional sodium alginate production process

A technology of sodium alginate and production process, applied in the field of seaweed chemical industry, can solve problems such as more consumption, and achieve the effects of reducing sewage charges, reducing COD emissions, and reducing direct production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

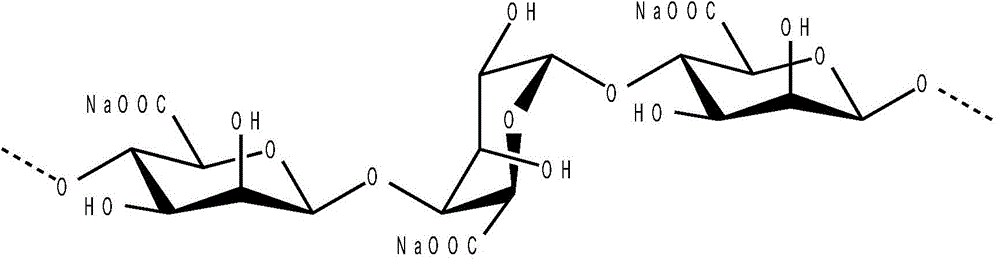

Image

Examples

Embodiment 1

[0017] Weigh 1000 kg of brown algae such as light dry kelp, Ascophyllum nodosum, blackened Leisong algae or bark algae as raw materials, and add 10000m 3 Soak in tap water for 1-2 hours. Use the pump (or use the kelp pump commonly used in the actual work of those skilled in the art) to pump the soaked raw materials to the twisted cage to filter out the water and chop them, then enter the press mill (sea sodium / HZM-100L) and adjust the grinding disc The gap is 0.5-2.0mm, and the screw speed of the press mill is adjusted at 2000rpm for 2min. The crushed seaweed is sent to the crusher (HC1600-90-300KW) for crushing for 10 minutes, then transferred to the buffer tank (ZS1-200) for 1.5 hours, and then transferred to the digestion tank to add Na with a concentration of 2.% (W / V) 2 CO 3 , 1000L and heated to 75°C for 6 hours. Transfer to a refining tank (gap ≥ 1mm) and grind for 2 minutes (kelp does not need to be refined, other macroalgae grind for 1-3 times), and finally transfe...

Embodiment 2

[0019] Weigh 1000 kg of brown algae such as light dry kelp, Ascophyllum nodosum, blackened Leisong algae or bark algae as raw materials, and add 10000m 3 Soak in tap water for 1-2 hours. Pump the soaked raw materials to the twisted cage to filter out the water through the giant algae pump, then chop them, and then enter the press mill (sea sodium / HZM-100L) and adjust the gap between the mill discs to 0.5-2.0mm, and adjust the screw speed of the press mill at 2000rpm. 2min. The crushed seaweed is sent to the crusher (HC1600-90-300KW) for crushing for 10 minutes, then transferred to the buffer tank (ZS1-200) for 1.5 hours, and then transferred to the digestion tank to add Na with a concentration of 2.% (W / V) 2 CO 3 , 1000L and heated to 75°C for 6 hours. Transfer to a refining tank (gap ≥ 1mm) for grinding for 2 minutes, and finally transfer to a stainless steel pot with a stirring and discharge port, add 130T tap water at room temperature and continue stirring until uniform....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com