Low-cost and high-wear-resistance TPR modified material and preparation method thereof

A modified material and high wear-resistant technology, which is applied in the field of low-cost and high wear-resistant TPR modified material and its preparation, can solve the problems of decreased elongation at break, difficult entry of polystyrene, phase separation, etc., to achieve Increased tensile strength, good air permeability, improved dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

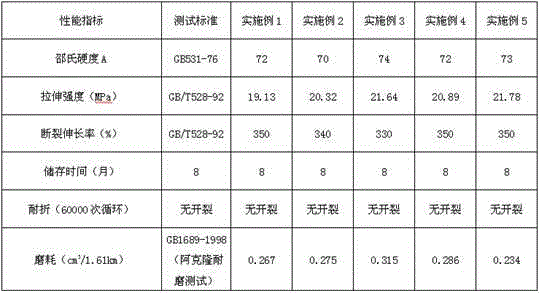

Examples

Embodiment 1

[0056] A low-cost and highly wear-resistant TPR modified material consists of the following substances by weight:

[0057] Oil-filled SBS 25 parts

[0058] SBS 10 copies

[0059] Recycled polystyrene material 10 parts

[0060] Butadiene-styrene copolymer 8 parts

[0061] Calcium carbonate 20 parts

[0062] 1 part anti-wear agent

[0063] 0.3 parts of yellow petroleum resin

[0064] 12 parts white mineral oil

[0065] Zinc stearate 0.1 part.

[0066] Wherein, the wear-resistant agent is prepared from oil-extended SBS: wear-resistant glue: zinc stearate in parts by weight of 58:38:1.5 with a twin-screw extruder.

[0067] The oil-extended SBS is prepared by mixing SBS, white mineral oil and polystyrene in a weight ratio of 100:40:35.

[0068] The reclaimed polystyrene recycled materials are purchased from the market.

[0069] A method for preparing a low-cost and high-wear-resistant TPR modified material, comprising the following steps:

[0070] Step 1, mixing and stirr...

Embodiment 2

[0074] A low-cost and highly wear-resistant TPR modified material consists of the following substances by weight:

[0075] Oil-filled SBS 35 parts

[0076] 5 copies of SBS

[0077] Recycled polystyrene material 20 parts

[0078] Butadiene-styrene copolymer 3 parts

[0079] Nano calcium carbonate 30 parts

[0080] Wear-resisting agent 0.5 parts

[0081] 0.8 parts of yellow petroleum resin

[0082] 12 parts white mineral oil

[0083] Zinc stearate 0.1 parts.

[0084] Wherein, the wear-resistant agent is prepared by mixing oil-extended SBS: wear-resistant rubber: zinc stearate at a ratio of 62:42:0.8 by weight and using a twin-screw extruder.

[0085] The oil-extended SBS is prepared by mixing SBS, white mineral oil and polystyrene in a weight ratio of 100:40:35.

[0086] The reclaimed polystyrene recycled materials are purchased from the market.

[0087] A method for preparing a low-cost and high-wear-resistant TPR modified material, comprising the following steps:

[...

Embodiment 3

[0092] A low-cost and highly wear-resistant TPR modified material consists of the following substances by weight:

[0093] Oil-filled SBS 28 parts

[0094] 8 copies of SBS

[0095] Recycled polystyrene material 15 parts

[0096] Butadiene-styrene copolymer 8 parts

[0097] Calcium carbonate 22 parts

[0098] 1 part anti-wear agent

[0099] 0.5 parts of yellow petroleum resin

[0100] 8 parts white mineral oil

[0101] Zinc stearate 0.5 part.

[0102] Wherein, the wear-resistant agent is prepared by mixing oil-extended SBS: wear-resistant rubber: zinc stearate in a ratio of 60:40:1 by weight and using a twin-screw extruder.

[0103] The oil-extended SBS is prepared by mixing SBS, white mineral oil and polystyrene in a weight ratio of 100:40:35.

[0104] The reclaimed polystyrene recycled materials are purchased from the market.

[0105] A method for preparing a low-cost and high-wear-resistant TPR modified material, comprising the following steps:

[0106] Step 1, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com