Epoxide hydrolase as well as encoding gene and application thereof

A technology of epoxides and coding genes, which is applied in the field of enzyme catalysis and can solve problems such as inability to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

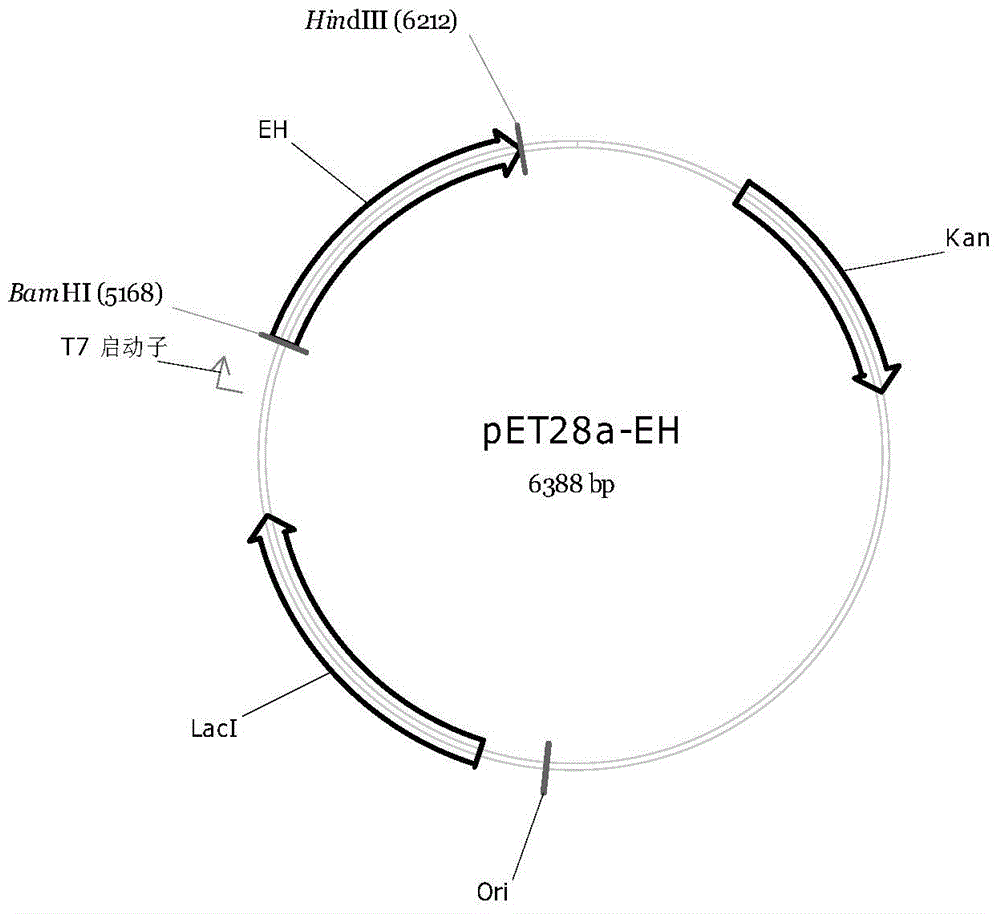

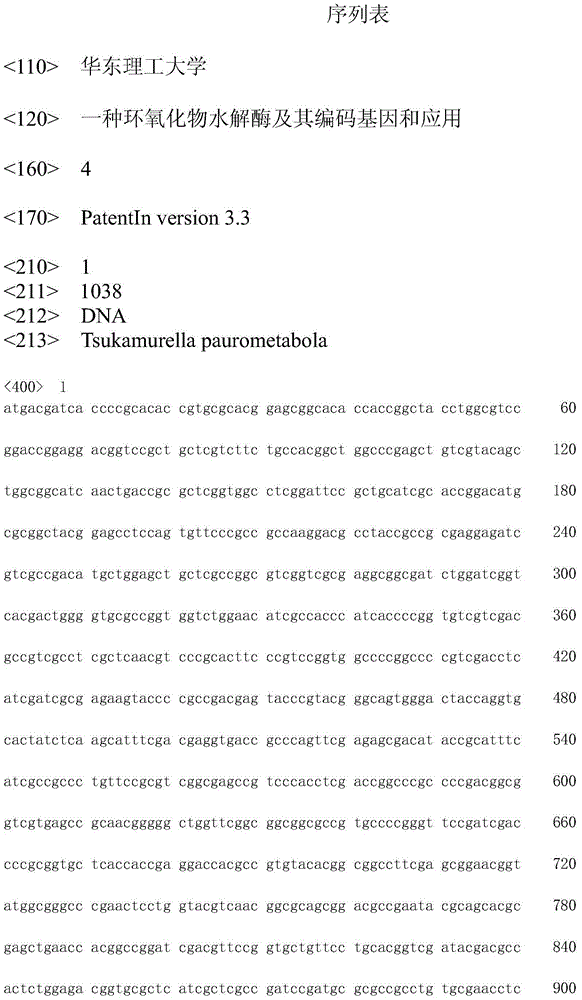

[0023] Example 1: Cloning containing epoxy hydrolase gene

[0024] Purchase a standard strain freeze-dried tube numbered DSM20162 from DSMZ, Germany.

[0025] 1LTsukamurella paurometabola medium is as follows: Trypticase Soy Broth (BBL11768, Oxoid CM129 or Merck 5459) 30.0g; distilled water 1000ml; PH7.3. Sterilize at 121°C for 15min. Incubate at 28°C in a constant temperature shaker at 200 rpm for 1 to 3 days, collect the bacteria by centrifugation, and extract the Tsukamurella paurometabola genome according to the instructions of the Gerui Bacterial Genome Extraction Kit, and amplify it with the following two primers:

[0026] F: 5’-CGC GGATCC ATGACGATCACCCCGCACACCGTG-3' (SEQ ID NO: 3);

[0027] R: 5’-CCC AAGCTT TCAGCCCGCGGGGTGGTTCTCC-3' (SEQ ID NO: 4);

[0028] The full length of the gene of the epoxy hydrolase is obtained.

[0029] Toyobo KOD enzyme PCR reaction system is: H 2 O 32.5ul, buffer 5ul, 2mm dNTP5ul, MgCl 2 2.5ul, template 2ul, 20mM F / R primer 1ul, KOD enzyme 1ul. Aft...

Embodiment 2

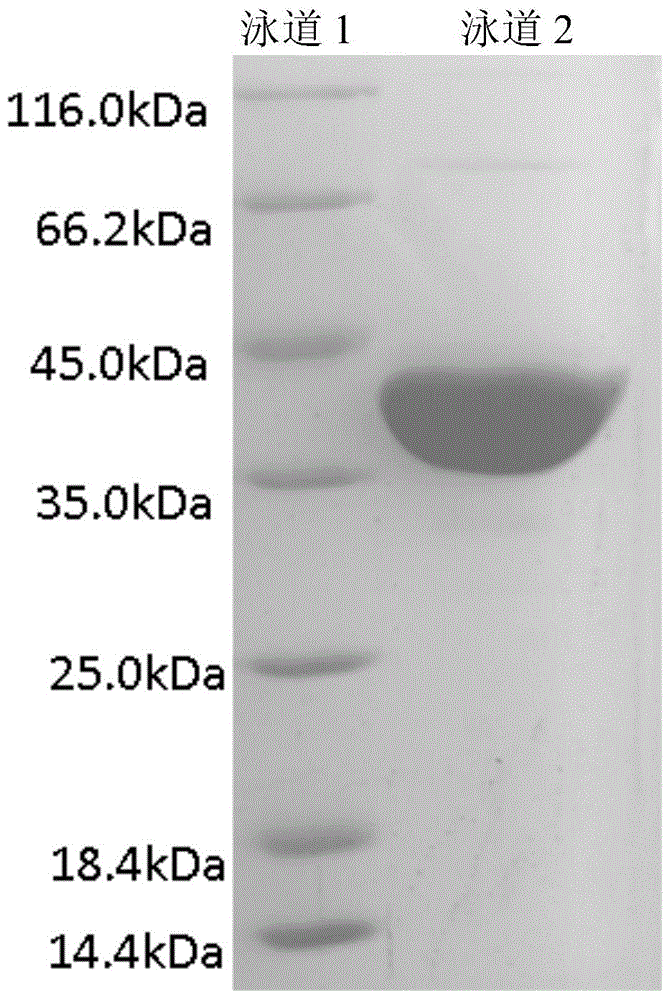

[0030] Example 2: Obtaining whole cells containing epoxy hydrolase

[0031] The obtained transformants were inoculated into LB liquid medium containing 50μg / ml kanamycin resistance, cultured at 37°C for 12h, and then inoculated with 1% of the inoculum amount (v / v) to freshly containing 50ug / ml kanamycin In the LB liquid medium resistant to mycin, culture at 37°C until the cell concentration OD600 is about 0.6, and then add IPTG with a final concentration of 0.1mM to the LB liquid medium. After inducing and culturing at 20°C for 20 hours, the culture solution is incubated at 4 Centrifuge at 8000 rpm for 10 min, discard the supernatant, and collect the precipitate, which is the recombinant E. coli BL21 / pET28a-EH wet bacteria containing the intracellular expression recombinant plasmid. Freeze-dried cells were obtained after the wet cells were freeze-dried for 4 hours. The formula of 1000ml LB medium is: peptone 10g, sodium chloride 10g, yeast extract 5g. The wet bacteria are broke...

Embodiment 3

[0032] Example 3: Application of the epoxy hydrolase in the preparation of R-phenyl glycidyl ether

[0033] The freeze-dried bacterial cells obtained in Example 2 were used as a catalyst. Dissolve 50 mg of lyophilized bacteria in 45 mL of 100 mM Trish-Hcl, mix well at 200 rpm for 5 min, and add 5 ml of racemic phenyl glycidyl ether dissolved in 4M DMSO at 200 rpm at 30° C. and terminate the reaction after 1 hour. Use 15ml n-hexane to extract three times to get ee> 99% R-phenyl glycidyl ether, then 15ml ethyl acetate extraction three times to get ee> 83% S-phenoxy glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com