Electroslag remelting method for large-scale, ultra-pure, high-performance nickel-base alloy 690

An electroslag remelting, nickel-based alloy technology, applied in the field of metal smelting, can solve the problems of uneven metal structure, segregation, etc., achieve the effect of homogenizing the structure, ensuring the structure, and reducing harmful elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

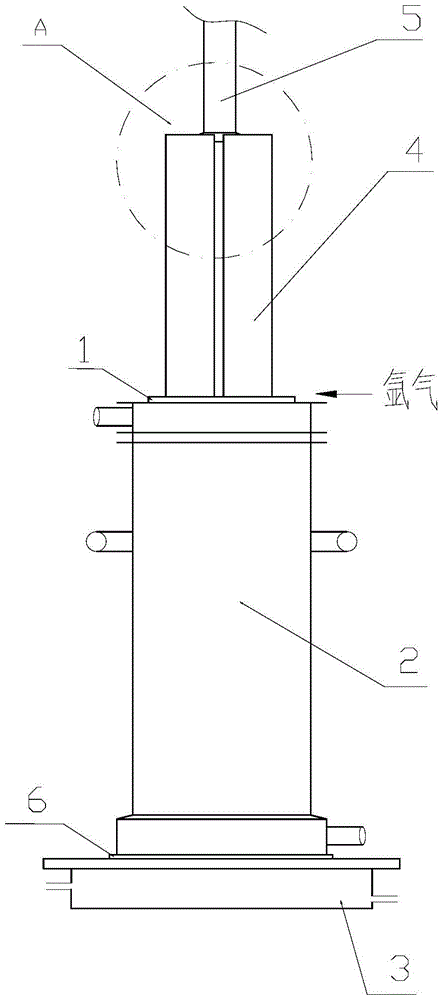

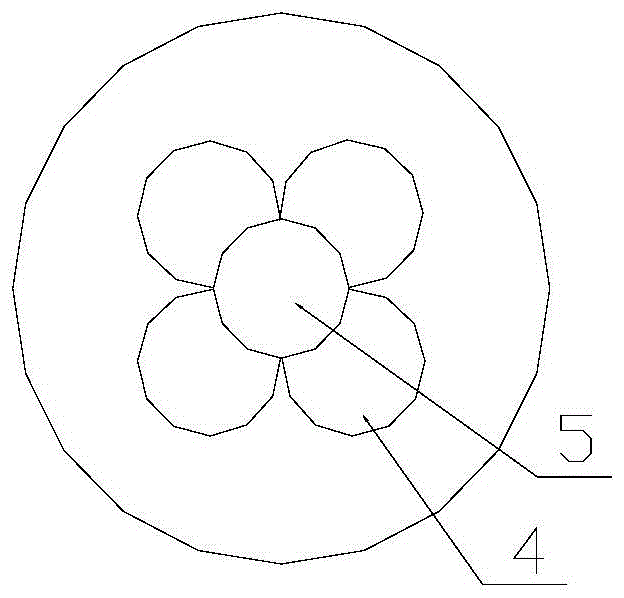

[0039] see Figure 1 ~ Figure 4 .

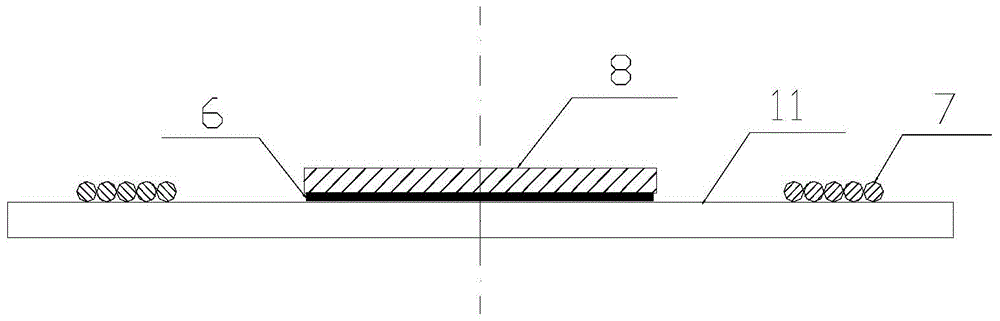

[0040] The electroslag remelting device includes a self-melting electrode, a crystallizer 2, a copper plate 11 and a bottom water tank 3. The self-melting electrode uses 4 ingots with the same outer diameter and same length as electrode rods 4 , and this embodiment uses vacuum ingots with a specification of Φ245×1200-1800 mm as electrode rods. The surface of the electrode rod is sanded and finished to ensure that the surface of the electrode rod has no defects such as heavy skin, fins, scars and slag inclusions, no obvious rust or scale, and the adhered grease and refractory material fragments are cleaned up. Weld 4 electrode rods side by side to form a matrix. The top of the electrode rods is connected with a dummy electrode rod 5 and baked at 800° C. for 10 hours.

[0041] In this embodiment, the crystallizer 2 is adopted to have an upper inner opening diameter of 860 mm, a lower inner opening diameter of 920 mm, and a length of 2250 mm;...

Embodiment 2

[0056] The difference with Example 1 is:

[0057] The weight percentage of the respective components of the slag used: CaF 2 : 70%; CaO: 8%; Al 2 o 3 : 12%; MgO: 10%. The amount of slag weighed 330kg.

[0058] The thickness of the launch pad is 40mm.

[0059] When blowing argon into the crystallizer, before remelting, the argon flow rate is 750L / min, and keep for 35min until there is almost no residual oxygen in the crystallizer; then adjust the argon flow rate to 260L / min until the remelting is completed.

[0060] The steady-state melting rate is controlled to be 15.2kg / min, the cooling water inlet temperature of the crystallizer is 20°C, and the outlet water temperature is 30°C.

[0061] The chemical composition analysis data and inclusion content of the alloy after remelting are shown in Table 3.

Embodiment 3

[0063] The difference with Example 1 is:

[0064] The weight percentage of each component of the slag used is: CaF 2 : 75%; CaO: 10%; Al 2 o 3 : 10%; MgO: 5%.

[0065] The thickness of the launch pad is 40mm.

[0066] When blowing argon into the crystallizer, before starting normal remelting, the argon flow rate is 800L / min, and keep it for 40min until there is basically no residual oxygen in the crystallizer; then adjust the argon flow rate to 300L / min until the remelting ends .

[0067] The steady-state melting rate was controlled to be 15.5 kg / min.

[0068] The chemical composition analysis data and inclusion content of the alloy after remelting are shown in Table 2. It can be seen from the data in Table 3 that the impurity elements of the 690 alloy after electroslag remelting are controlled at a low level, and the purpose of purification is achieved.

[0069] Table 2 Partial element composition (wt%) and inclusions of 690 alloys of different slag series electroslag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com