Hafnium-base mixed metal material and iodination preparation method thereof

A technology for the preparation of mixed metals and iodination, which is applied in the field of synthesis and preparation of mixed metal materials, can solve problems such as the inability to ensure uniform product components and low production efficiency, and achieve continuous batch production, high production efficiency, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

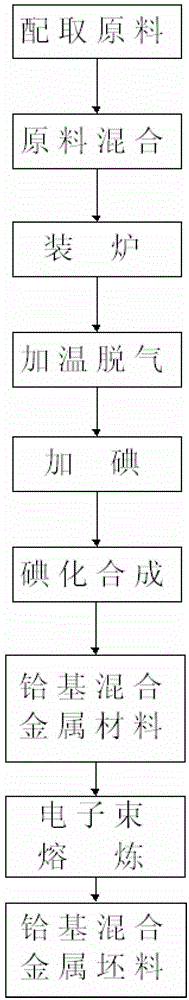

[0036] A method for preparing hafnium-titanium mixed metal material by iodination, comprising the following steps:

[0037] (1) Weigh 99.9wt.% of the base metal hafnium and 0.01wt.% of titanium, a total of 30kg. The particle size of hafnium and titanium is about 3-5mm, and they are evenly mixed; the purity of hafnium and titanium are both 99.9wt.%.

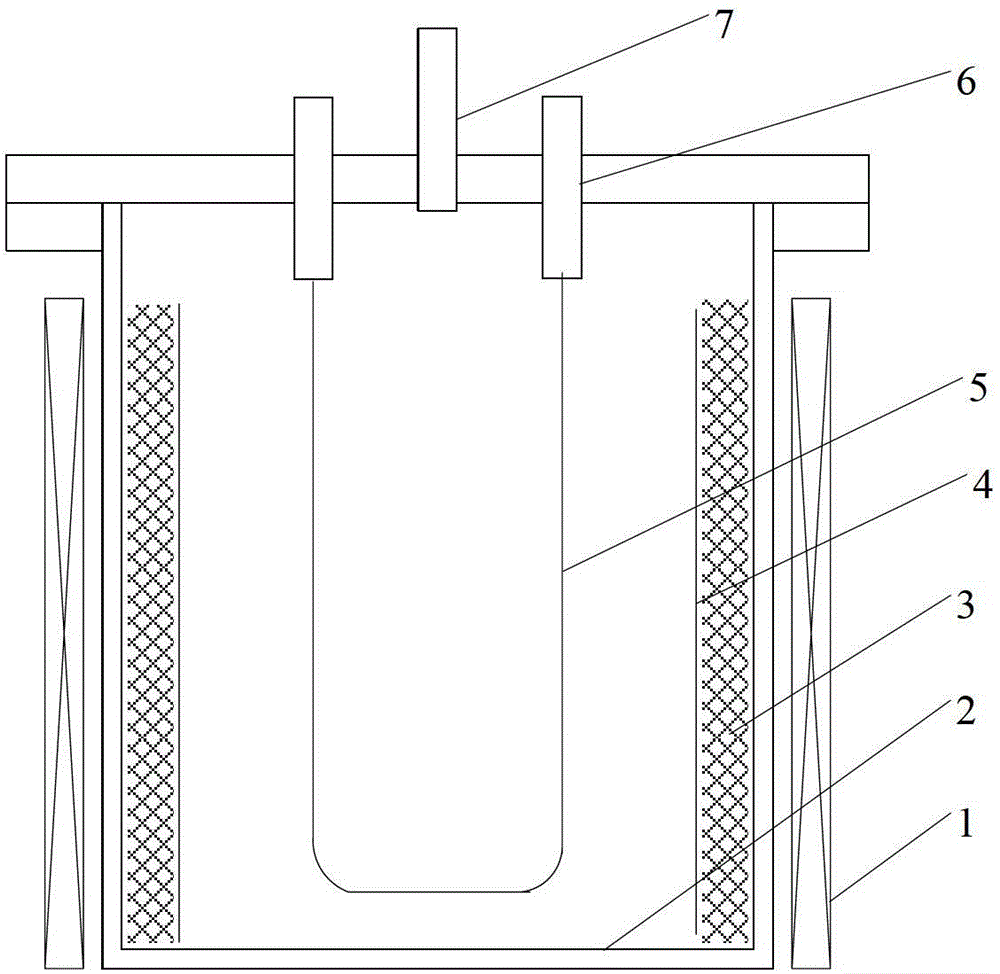

[0038] (2) Put the mixed metal raw material 3 into the iodination device, install it between the molybdenum mesh 4 and the inner wall of the reaction tank 2, and evacuate it to 1×10 -3 Pa, start the iodination reaction, add 300g of solid iodine into the reaction tank 2 with a certain temperature through the iodine adding device 7, and the generated iodine vapor reacts with the metal elements Hf and Ti in the raw material at a temperature of about 500 °C Volatile iodides are generated, and the generated volatile iodides are transferred to the mother wire 5 with a temperature of about 1300°C and passed through an electric current, ...

Embodiment 2

[0041] A method for preparing hafnium-zirconium mixed metal material by iodination, comprising the following steps:

[0042] (1) Weigh 90wt.% of the matrix metal hafnium and 10wt.% zirconium, 20kg in total, the particle size of hafnium and zirconium are both about 2-5mm, mix well; the purity of each metal element is 99.9wt.%;

[0043] (2) Put the mixed metal raw materials into the iodination device and vacuumize to 5×10 -3 Pa, start the iodination reaction, the amount of iodine added in the iodination device is 200g, Hf and Zr react with iodine vapor at a temperature of 400°C to generate volatile iodide, and the generated volatile iodide is transferred to 1250°C On the mother wire at a temperature of about 100%, it decomposes to form a hafnium-zirconium mixed metal material; the reaction process is about 20 hours, and the purity of the obtained hafnium-zirconium mixed metal material is 99.95w%, and the composition of hafnium and zirconium in the material has a certain proporti...

Embodiment 3

[0046] A method for preparing hafnium-zirconium-titanium mixed metal material by iodination, comprising the following steps:

[0047] (1) Weigh 70wt.% of matrix metal, 20wt.% zirconium and 10wt.% titanium, a total of 15kg, the particle size of hafnium, zirconium and titanium are all about 1-6mm, mix well; the purity of each metal element is 99.9% ;

[0048] (2) Put the mixed metal raw materials into the iodination device and vacuumize to 1×10 -3 Pa, the iodination reaction starts, the amount of iodine added in the iodination device is 300g, Hf, Zr and titanium react with iodine vapor at a temperature of about 500°C to generate volatile iodide, and the generated volatile iodide is transmitted On the mother wire at a temperature of about 1300°C, it decomposes to form a hafnium-zirconium-titanium mixed metal material; the reaction process is about 30 hours, and the purity of the obtained hafnium-zirconium-titanium mixed metal material is 99.95w%. The composition and raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com