High-strength safety net

A safety net and high-strength technology, applied in the field of safety net, can solve the problems of poor safety of grinding discs and failure to meet the requirements of rotary safety line speed, etc., and achieve the effect of improved grinding efficiency, strong consistency and efficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

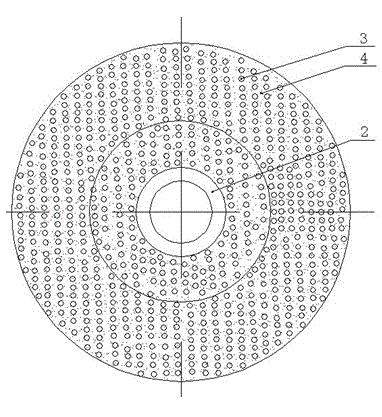

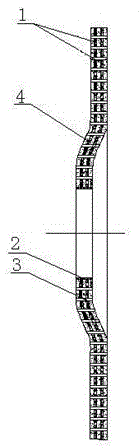

[0011] As shown in the drawings, a high-strength safety net includes two base layers 1 interwoven with glass fiber filaments. The center of the base layer 1 is provided with an iron ring 2. An abrasive layer 4 is adhered to the base layer 1. On the base layer 1 Mesh 3 is provided.

[0012] The base layer 1 is cymbal-shaped.

[0013] The abrasive layer 4 is a corundum abrasive layer or a silicon carbide abrasive layer.

[0014] The abrasive layer 4 is an abrasive layer with an abrasive particle size of 24-120 mesh.

[0015] The preparation process of the matrix in the present invention is as follows: the high-strength glass fiber filaments are surface-actively treated, interwoven into a 6-16-mesh mesh body, cut into a disc shape with a diameter of 100-180mm, and immersed in a phenolic modified epoxy resin chemical In the adhesive solution, after the glue is left quantitatively by the high-speed centrifuge, abrasive materials with various properties are bonded as the grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com