Lightweight composite material supporting structural component for track traffic tunnel and mounting method thereof

A composite material and rail transportation technology, applied in the field of new composite materials, can solve the problems of heavy component transportation, affecting the safe operation limit of trains, increasing the difficulty of construction, etc., to improve stiffness and bearing capacity, reduce tunnel maintenance costs, simplify The effect of construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

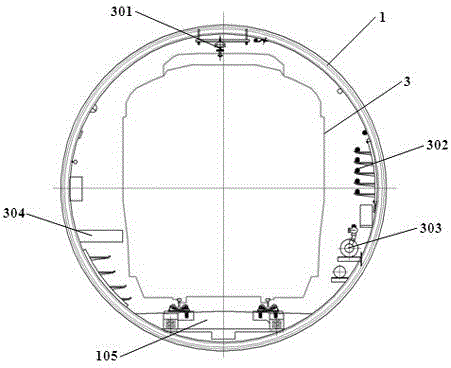

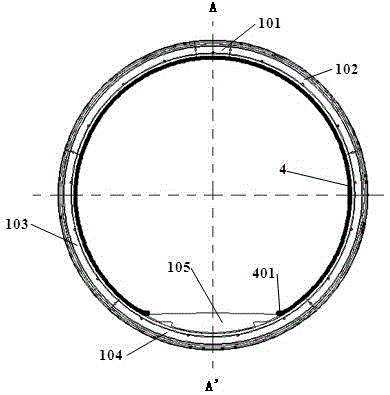

[0043] Such as figure 1As shown, the vehicle safe operation limit 3 of the subway tunnel is not allowed to be invaded, and a power supply catenary system 301, a feeder cable 302, a fire-fighting water pipe 303, an escape platform 304 and other facilities are installed in the tunnel. These facilities (power supply catenary system 301, feeder cable 302, fire water pipe 303) should be removed temporarily before the tunnel maintenance work, leaving space for the carbon fiber composite braid 4 (see Figure 3) to be pasted and installed. For intermittent escape platform 304, make corresponding treatment according to conventional tunnel construction measures.

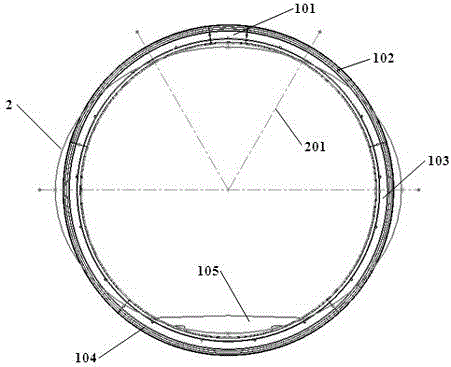

[0044] The tunnel segment 1 includes a wedg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com