Method for Determination of Sulfur Content in Quicklime by Conductometric Method

A technology of sulfur content and quicklime, which is applied in the preparation of test samples, material resistance, etc., can solve the problems of low measurement efficiency, different sulfur conversion rates, and inability to keep up with titration speed, etc., to improve the measurement accuracy and work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The method that conductometric method of the present invention measures sulfur content in unslaked lime comprises the steps:

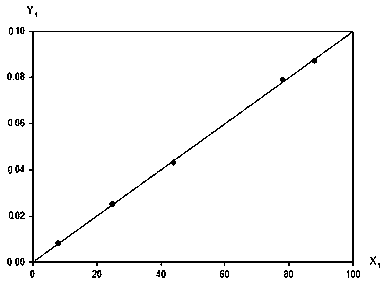

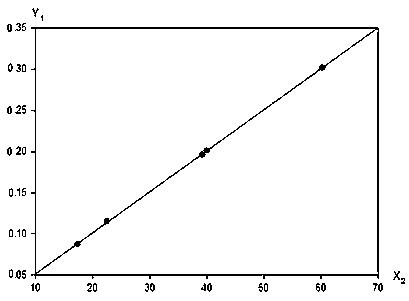

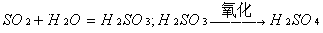

[0023] Step 1, establish a calibration curve, respectively take five parts of low-content limestone standard samples and high-content limestone standard samples of different sulfur contents, each part of low-content limestone standard sample weighs 0.5000g, and each part of high-content limestone standard sample weighs 0.1000g, each low-content limestone standard sample and high-content limestone standard sample were spread in a porcelain boat, and 2.5g of linear copper oxide was evenly spread on it, and then placed in a tube-type high-temperature furnace and burned for 5 minutes under oxygen flow. The furnace temperature is set at 1400°C, the gas after combustion is collected in the aqueous solution containing oxidant, and the conductivity analyzer is used to detect the conductivity value of the aqueous solution collected after the combustion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com