Optical fiber and silicon waveguide coupling structure based on polymer waveguides and manufacturing method thereof

A coupling structure and polymer technology, applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of complex process and low reliability of optical fiber coupling structure, reduce process complexity, ensure reliability, and improve coupling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

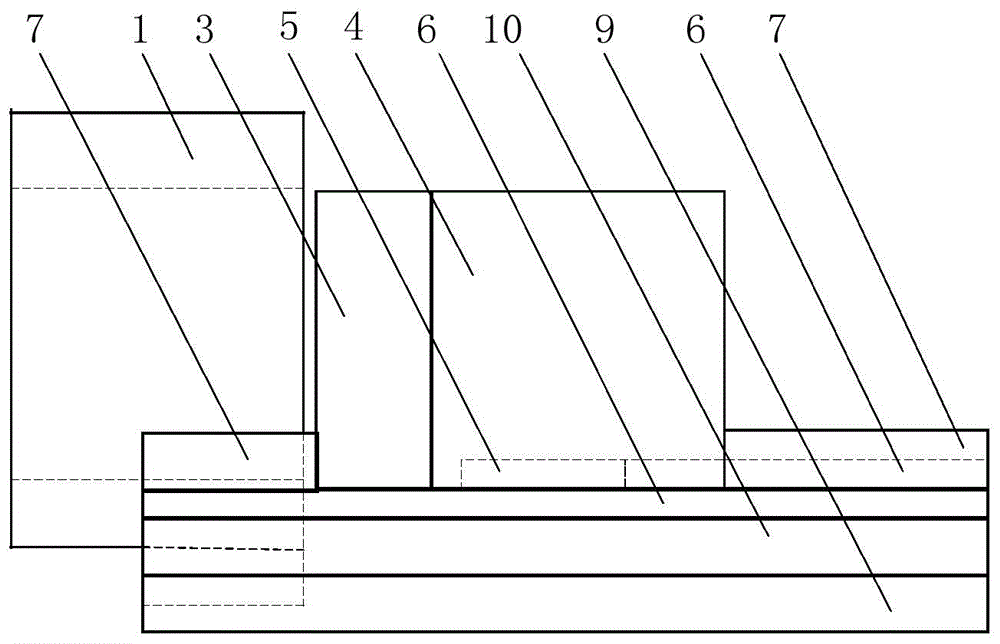

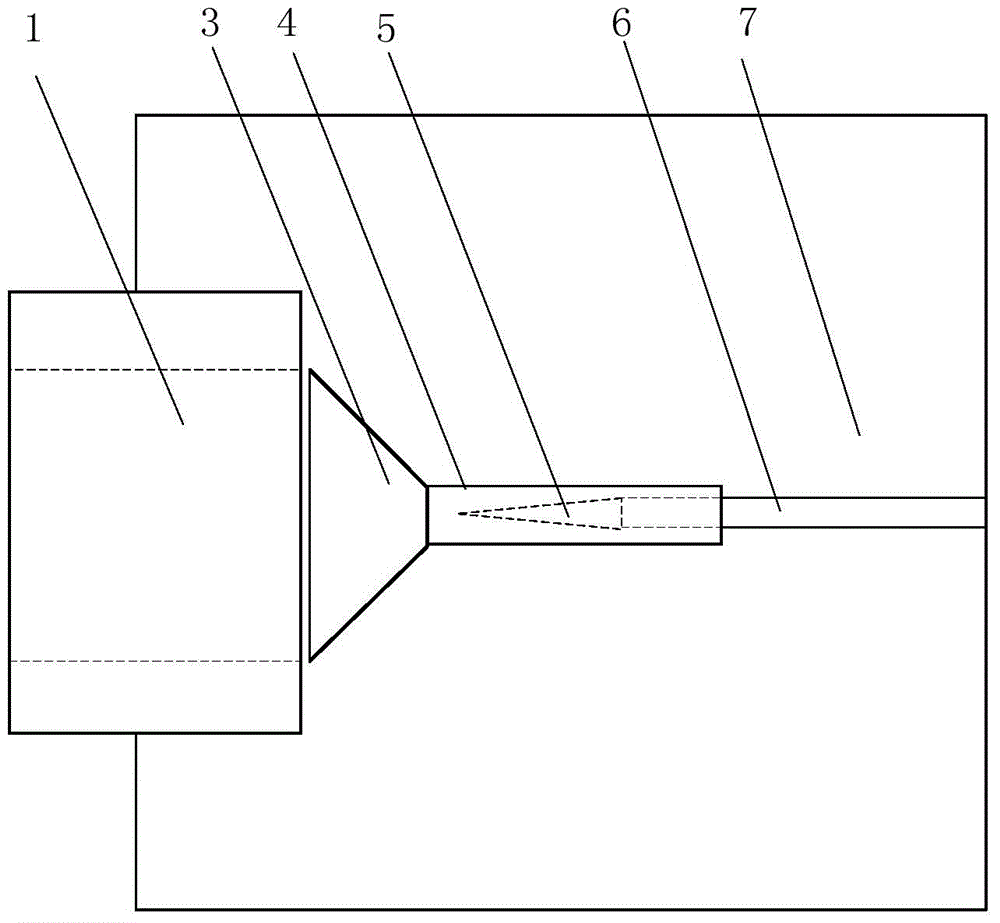

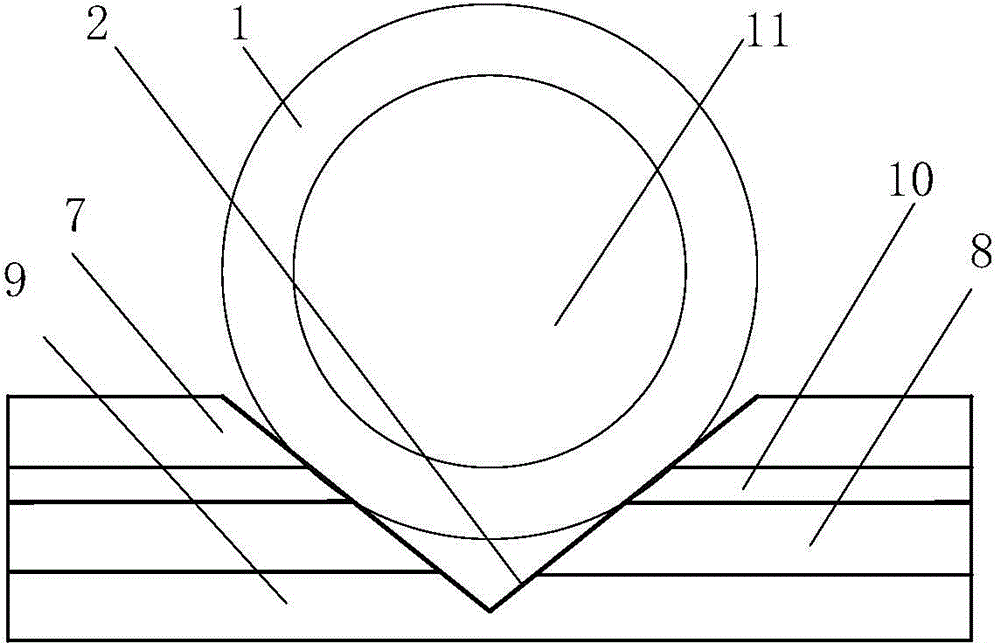

[0025] Such as figure 1 , 2 As shown in 3 and 3, the optical fiber and silicon waveguide coupling structure based on polymer waveguide provided by the present invention includes an SOI (Silicon-On-Insulator, silicon-on-insulator) wafer and an optical fiber 1 disposed on the SOI wafer.

[0026] The SOI wafer includes an upper layer silicon 10, a buried oxide layer 8 and a substrate silicon 9 from top to bottom;

[0027] The upper layer of silicon 10 is provided with polymer straight waveguides 4 and polymer tapered waveguides 3 arranged in sequence from right to left, and the part of the upper layer of silicon 10 where the polymer straight waveguides and polymer tapered waveguides are not arranged is covered with a layer of silicon dioxide. Layer 7, the narrow end of the polymer tapered waveguide 3 is connected to the polymer straight wavegu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com