A kind of preparation method of composite solar cell

A technology for preparing solar cells and thin films, which is applied in the field of solar cells and can solve problems such as CdS thin film material falling off and device damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

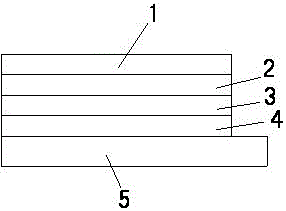

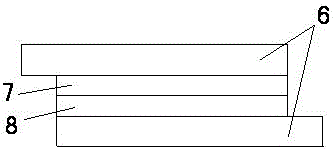

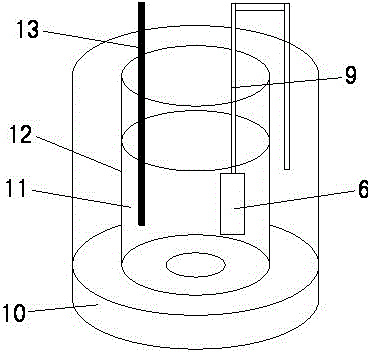

[0025] see Figure 1 to Figure 3 , the embodiment of the present invention includes:

[0026] A method for preparing a composite solar cell. First, the cleanliness and flatness of the conductive glass have a great influence on the quality of the film, and the conductive glass needs to be pretreated. The conductive glass is indium tin oxide (ITO) of 20mm×80mm×lmm Conductive glass; the pretreatment process of conductive glass includes: (1), soak the conductive glass in concentrated nitric acid for 15 minutes, take it out and rinse it in deionized water; (2), soak the conductive glass in 10% NaOH solution for 15 minutes, Then rinse with deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com