Broad-spectrum corrosion-resistant water ring vacuum pump

A technology of water ring vacuum pump and corrosion resistance, which is applied in the field of broad-spectrum corrosion resistant water ring vacuum pump, can solve problems such as reduction, achieve the effects of enhancing wear resistance, solving easy cavitation, and improving anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

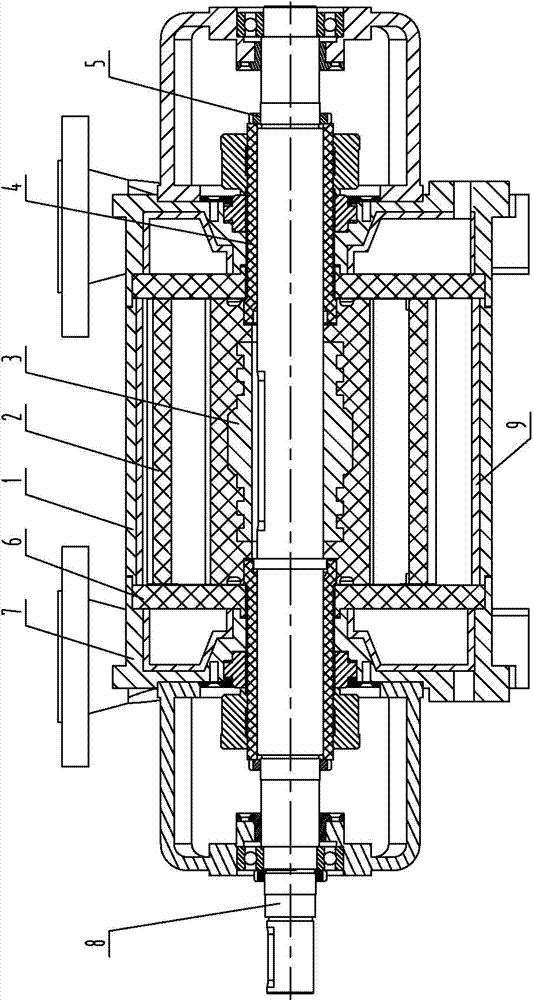

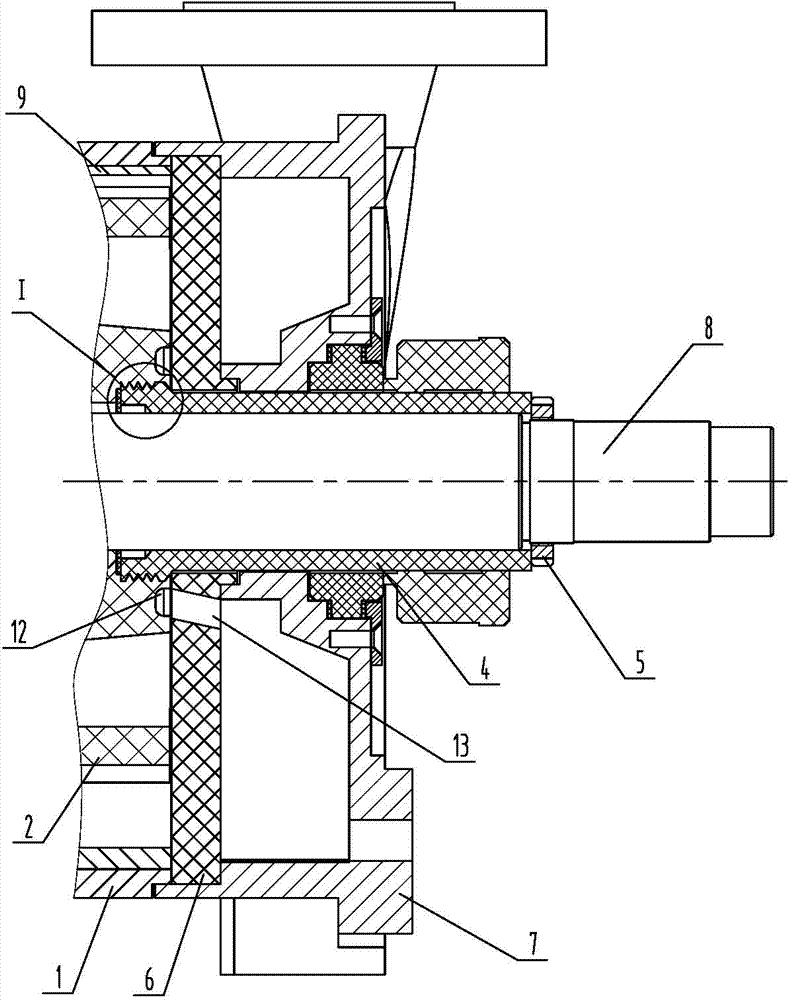

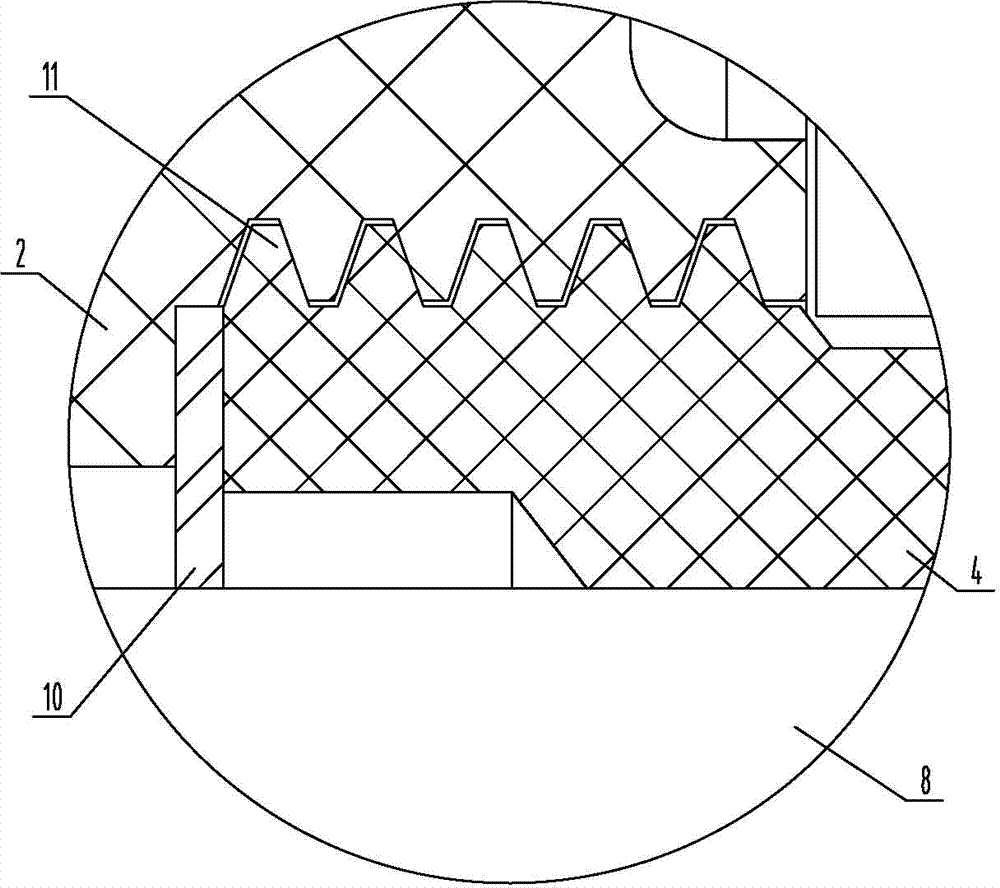

[0022] like figure 1 and figure 2 As shown, the materials of the pump body 1 , the pump cover 7 and the pump shaft 8 of the present invention are all cast steel, which ensures the mechanical strength of the water ring vacuum pump under the premise of controlling the material cost. The impeller 2 is set on the pump shaft 8, and the disc 6 is set at both ends of the impeller 2. The inner wall of the pump body 1 and the pump cover 7 is melted and pressed with polyvinylidene fluoride lining 9; the pump shaft 8 at both ends of the impeller 2 is The sleeve sleeve 4, the disc 6, the sleeve 4 and the impeller 2 are all formed by melting and pressing polyvinylidene fluoride, and the molded products have good mechanical strength and toughness due to the high melt viscosity of polyvinylidene fluoride; And in a wide temperature range, it is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com