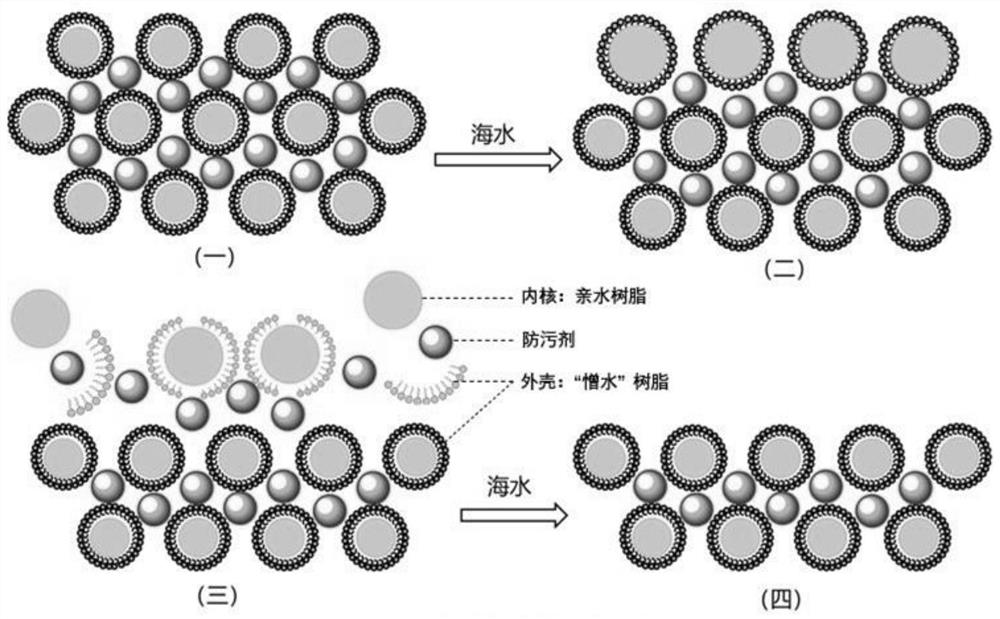

Novel marine antifouling coating composition based on nano-microcapsule controlled release technology

A technology of nano-microcapsules and antifouling coatings, applied in the field of coatings, can solve the problems of easy large-area shedding of coatings, low utilization efficiency of antifouling agents, and unstable release rates, so as to solve the problems of easy shedding of coatings and improve comprehensive mechanics performance, the effect of improving toughness and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Implementation Example 1: Broad-spectrum and high-efficiency copper-containing marine antifouling coating composition based on nano-microcapsule controlled release technology

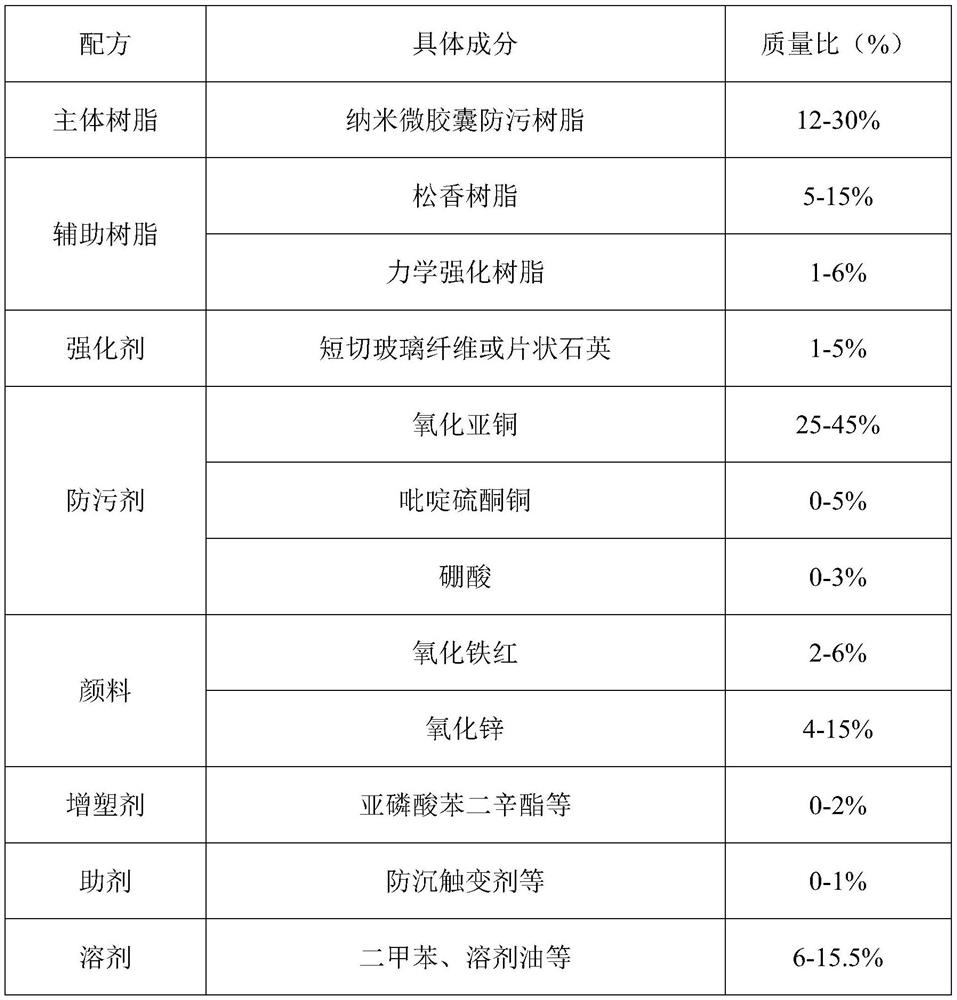

[0084] The broad-spectrum high-efficiency copper-containing marine antifouling coating composition based on nano-microcapsule controlled release technology is a one-component antifouling coating. The overall formula is shown in the following table:

[0085]

[0086] The total amount of the above components is 100%. The mechanical strengthening resin is one or more of butyl resin, styrene-butadiene resin, phenolic resin, alkyd resin, amino resin, urea-formaldehyde resin, and polyester resin. The strengthening agent is glass fiber, flake quartz, etc. The antifouling agent is one or more of cuprous oxide, copper pyrithione, zinc pyrithione, zinc zinc, boric acid, SeaNine 211, and bromopyrrole nitrile. Auxiliary antifouling agents are metopyridine, borneol, propylene glycol menthyl carbonate, bo...

Embodiment 2

[0092] Implementation Example 2: Economical copper-containing marine antifouling coating composition based on nano-microcapsule controlled release technology

[0093]The formulation of the economical copper-containing marine antifouling paint composition based on nano-microcapsule controlled-release technology is shown in the table below:

[0094]

[0095] The total amount of the above components is 100%.

[0096] Representative antifouling paint formulation composition:

[0097] name 1A2A 1A2B 1A2C 1B2A 1B2B 1B2C 1C2A 1C2B 1C2C Nano microcapsule antifouling resin 20 20 20 12 30 20 14 20 20 rosin 9 9 9 5 5 9 15 9 9 3136-2 alkyd resin 2 1 2 2 2 2 6 2 2 chopped glass fiber 1 2 2 2 4 5 2 2 2 Cuprous oxide 38 38 25 45 38 38 35 38 38 copper pyrithione 3 3 5 3 0 3 3 3 3 boric acid 1.5 0 1.5 1.5 1.5 3 1.5 1.5 1.5 Iron Oxide Red 5 2 5 6 5 5 4 5 ...

Embodiment 3

[0101] Implementation Example 3: New copper-free and tin-free marine antifouling coating composition based on nano-microcapsule controlled release technology

[0102] The formulation of the new copper-free and tin-free marine antifouling coating composition based on nano-microcapsule controlled release technology is shown in the following table:

[0103]

[0104] The total amount of the above components is 100%. The mechanical strengthening resin is one or more of butyl resin, styrene-butadiene resin, phenolic resin, alkyd resin, amino resin and polyester resin. SeaNine 211, pyrithione zinc, boric acid, pyridinetriphenylboron, bacteriozam, bromopyrrolecarbil, and metoprimidine are selected as antifouling agents. The anti-sedimentation thixotropic agent is selected from organic bentonite, polyamide wax slurry or fumed silica.

[0105] Representative antifouling paint formulation composition:

[0106] name 1A2A 1A2B 1A2C 1B2A 1B2B 1B2C 1C2A 1C2B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com