Patents

Literature

55 results about "Copper pyrithione" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

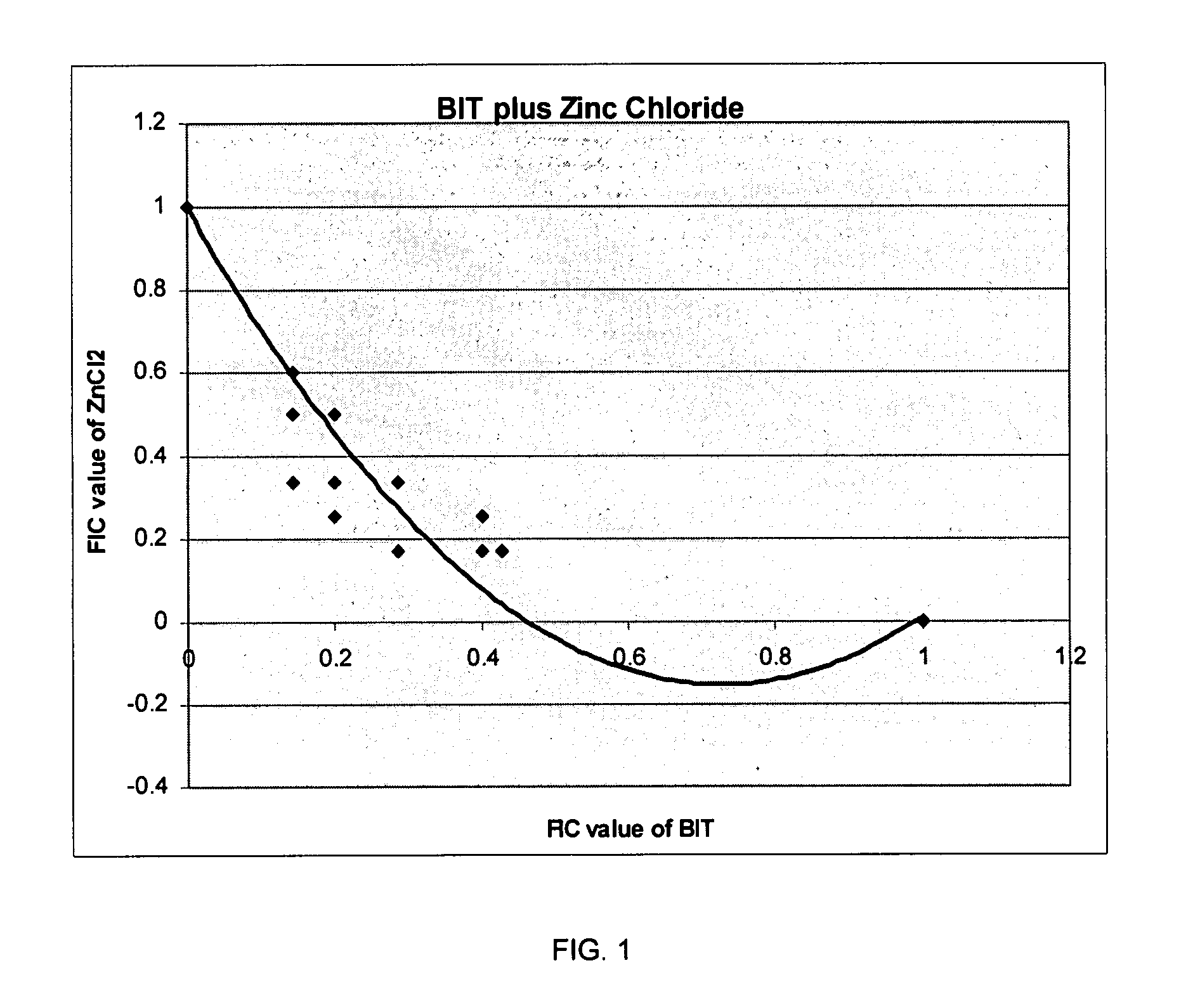

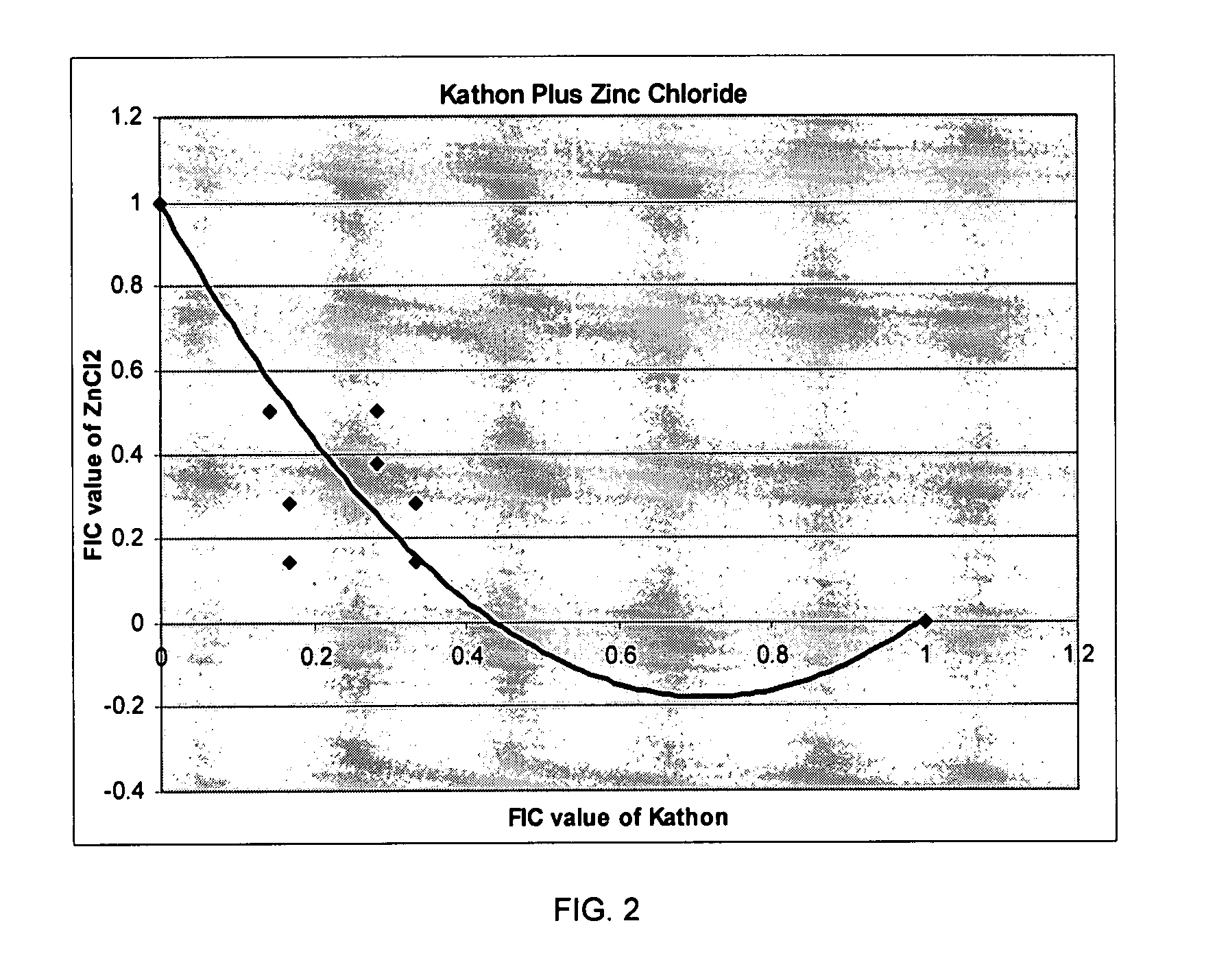

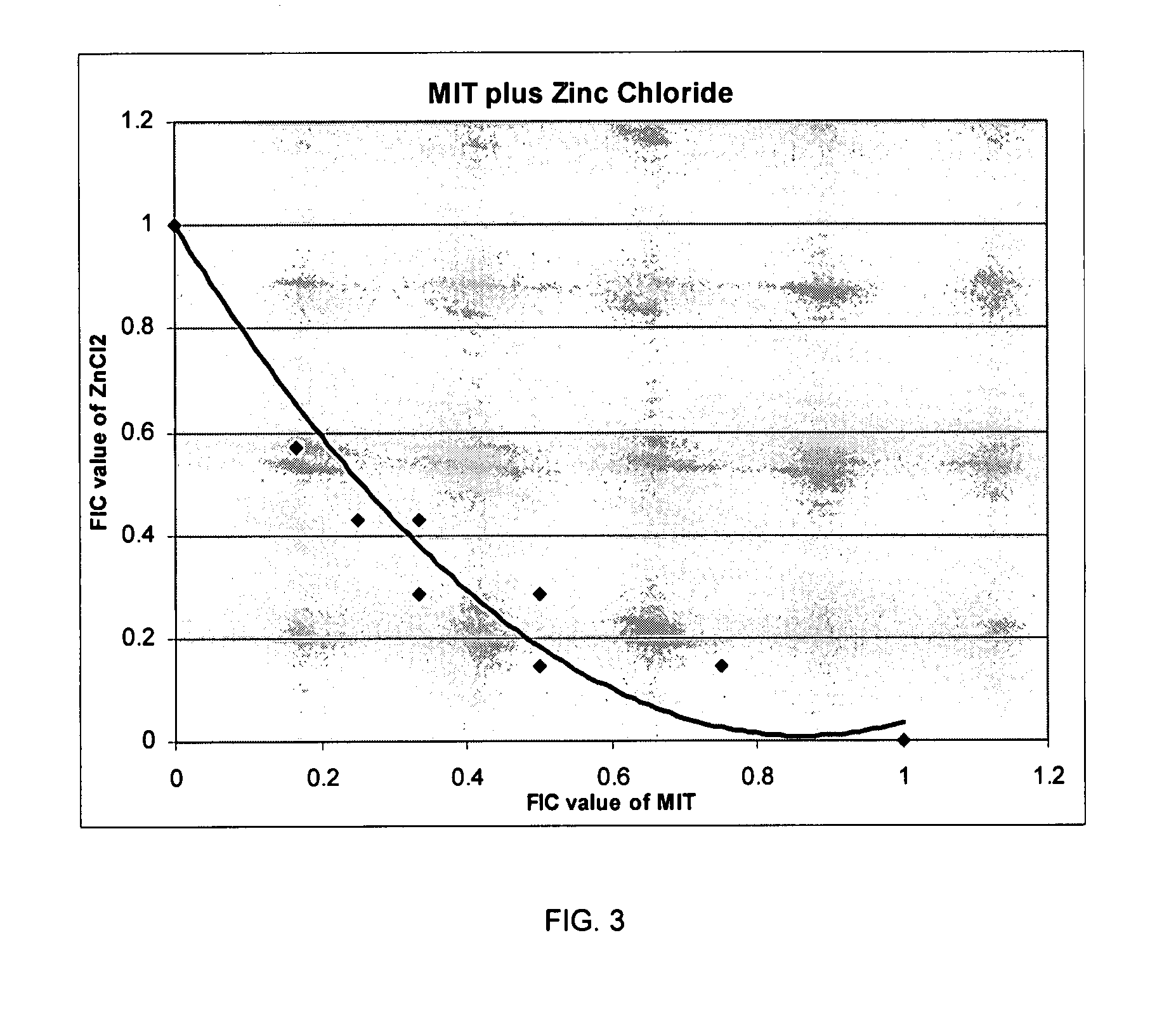

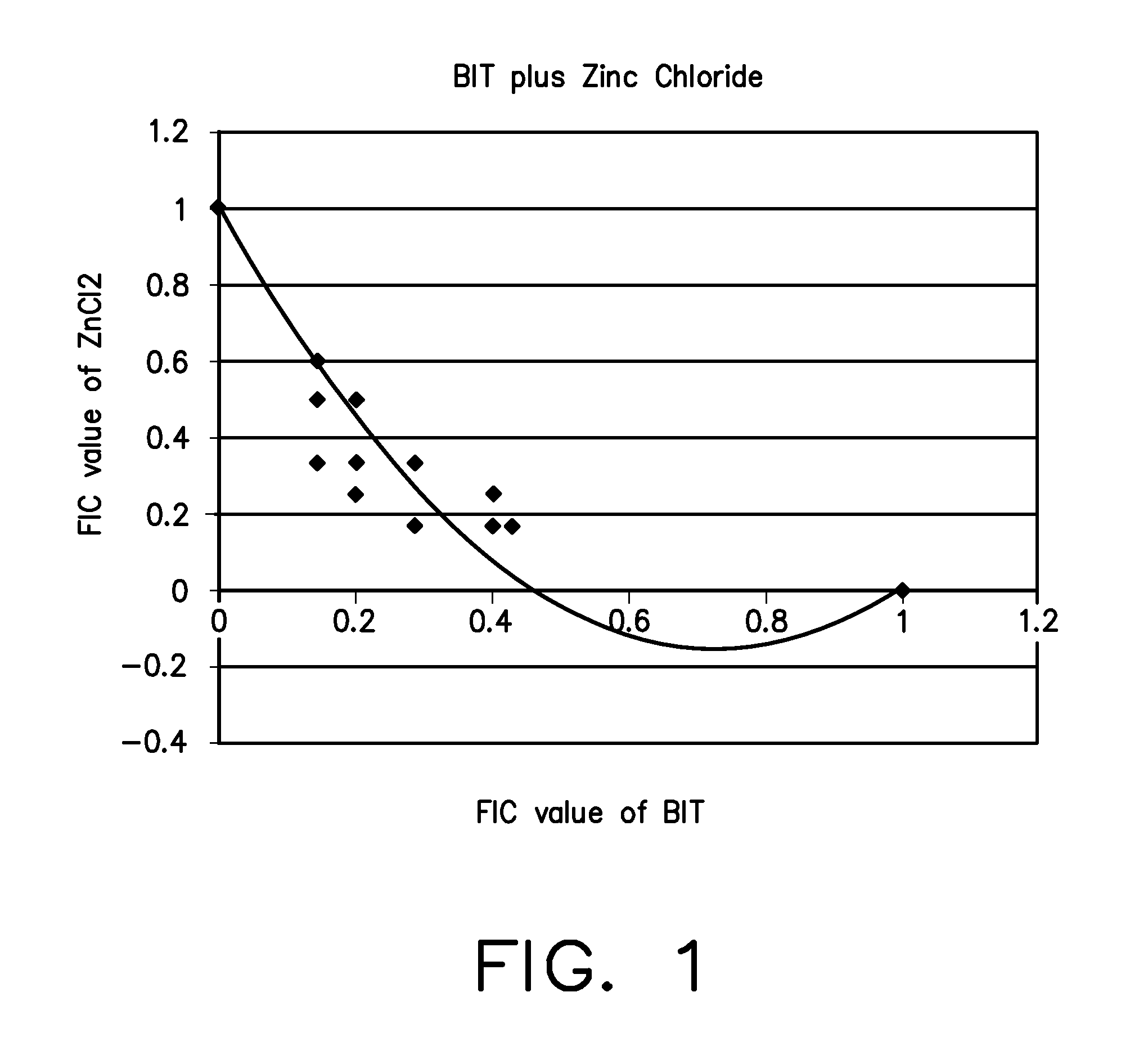

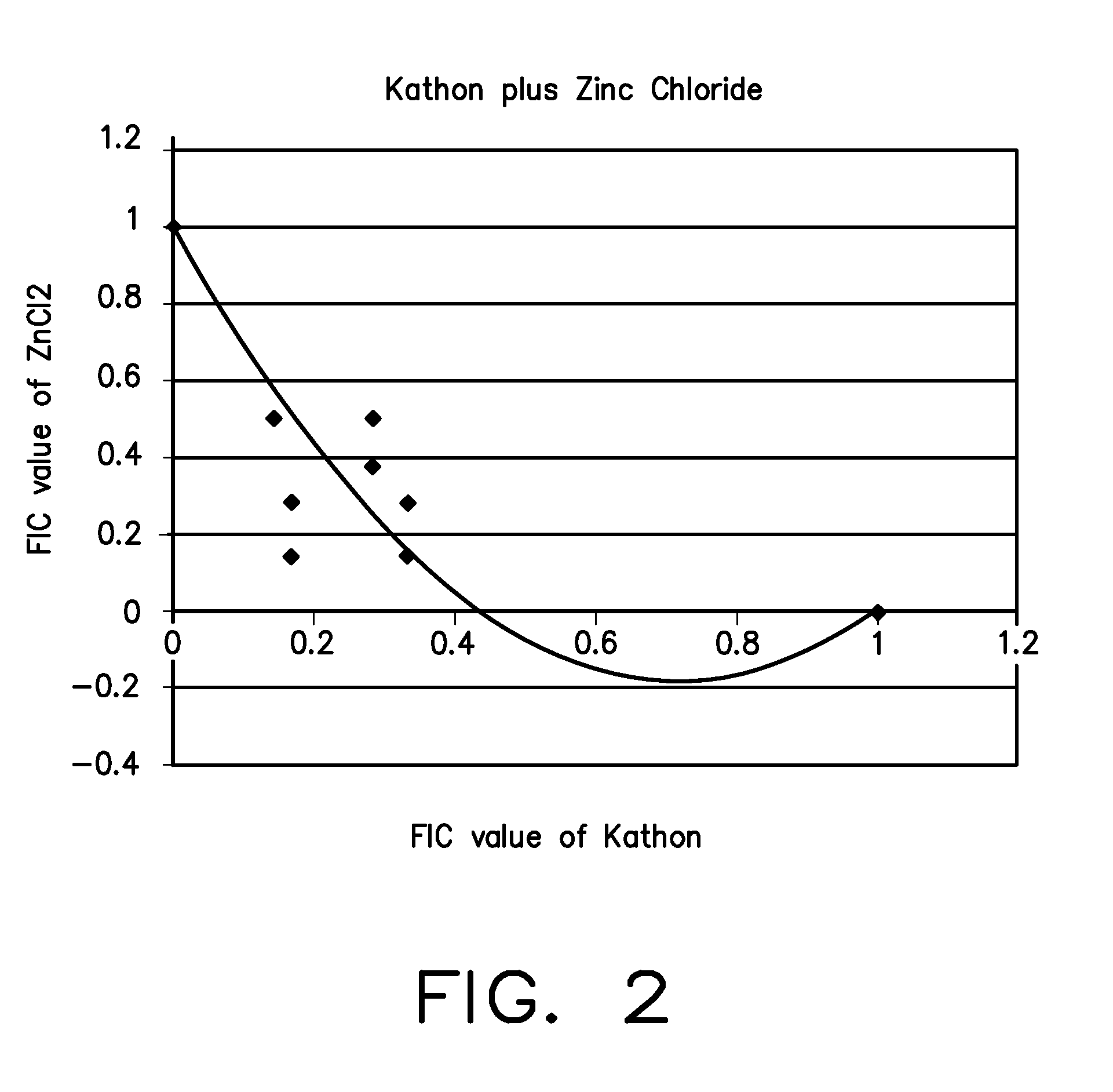

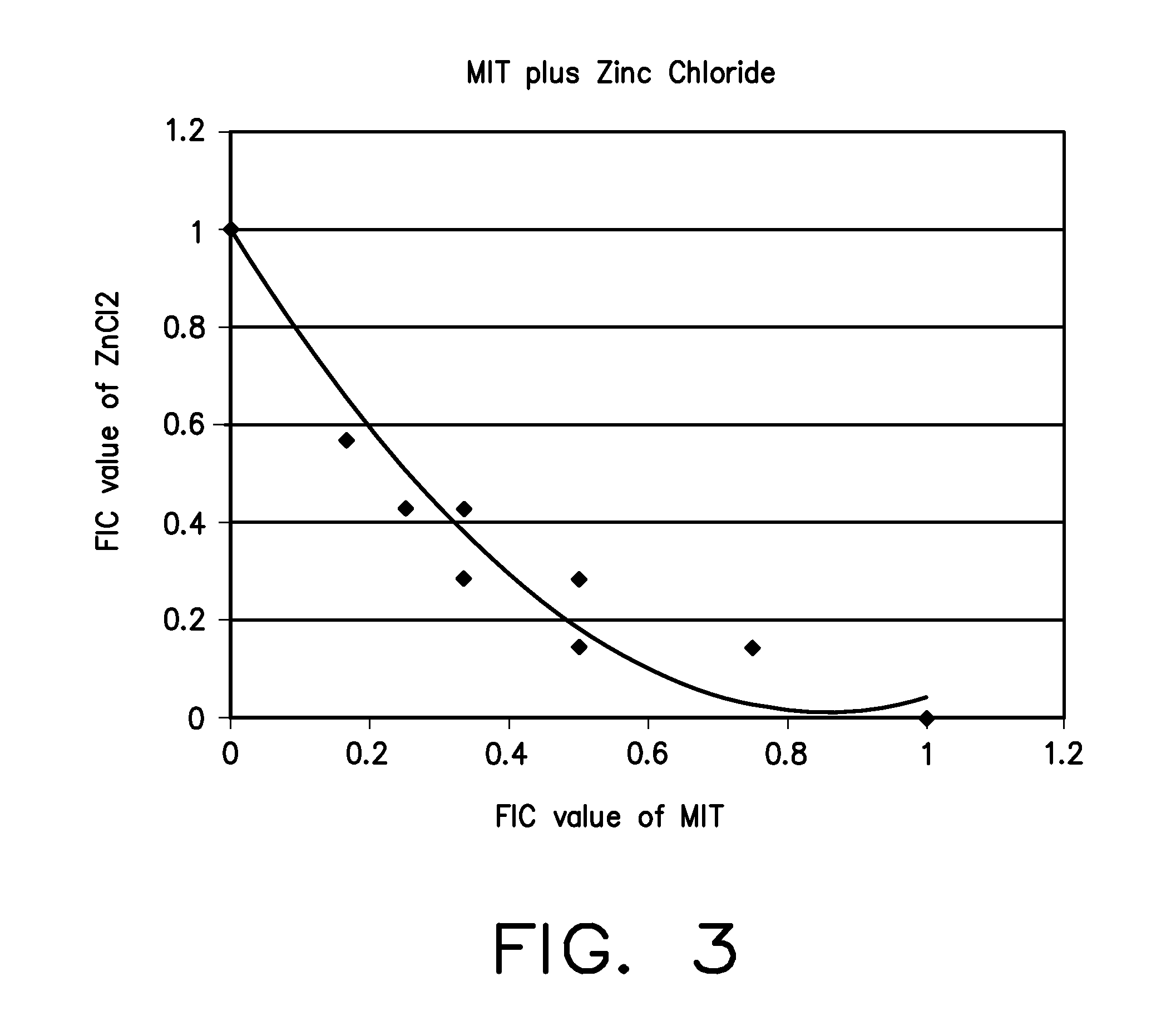

Isothiazolinone biocides enhanced by zinc ions

The present invention relates to an antimicrobial composition comprising an isothiazolinone, such as 1,2-benzisothiazolin-3-one, and a zinc compound selected from zinc salts, zinc oxides, zinc hydroxides or combinations thereof. Useful zinc salts include for example, oxides, sulfates, chlorides, and combinations thereof. In use, the zinc from the zinc compound enhances the antimicrobial activity to the isothiazolin-containing composition. This enhancement permits achieving the desired antimicrobial activity at a lower usage rate than is achieved using the isothiazolinone in the absence of the zinc compound. The antimicrobial composition can also contain co-biocides, such as pyrithiones, including zinc pyrithione or copper pyrithione.

Owner:ARCH CHEM INC

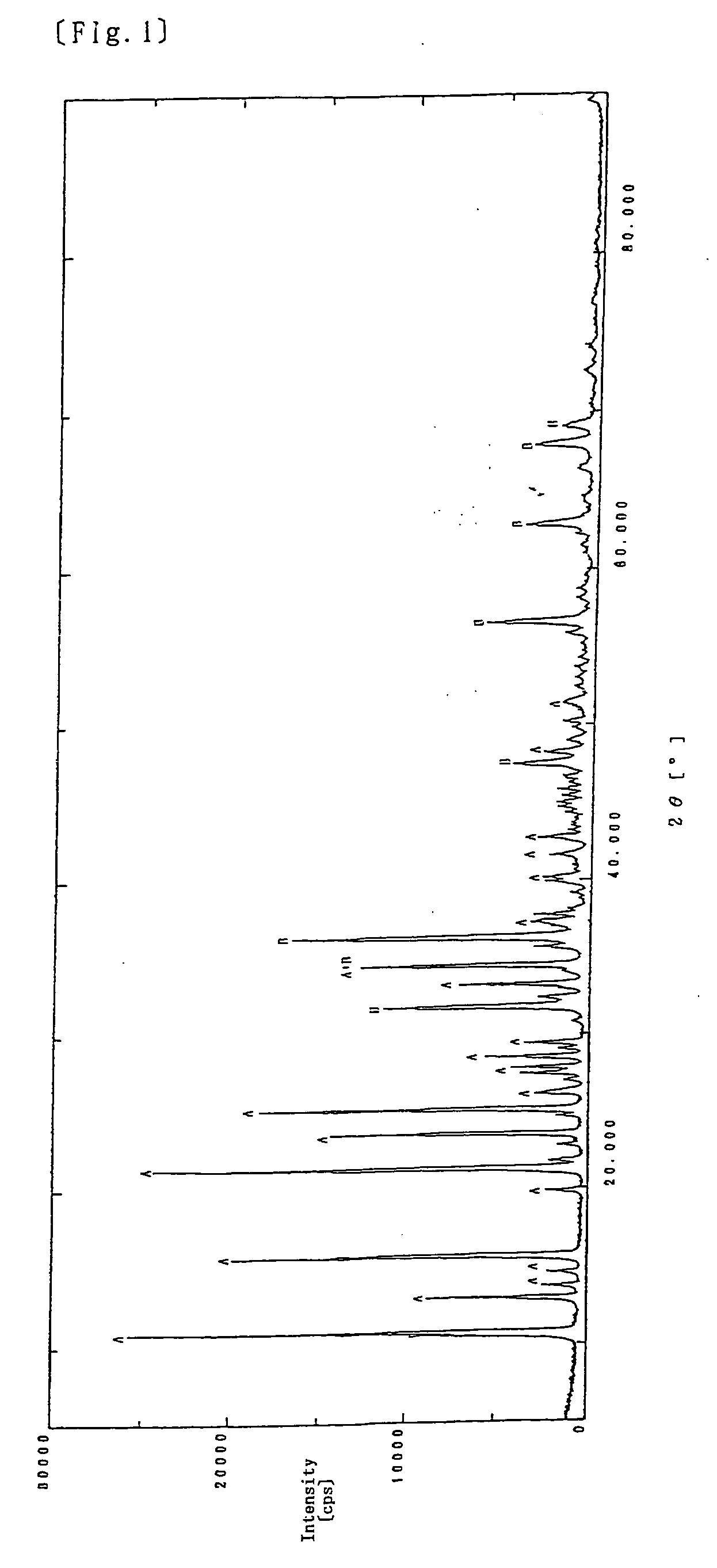

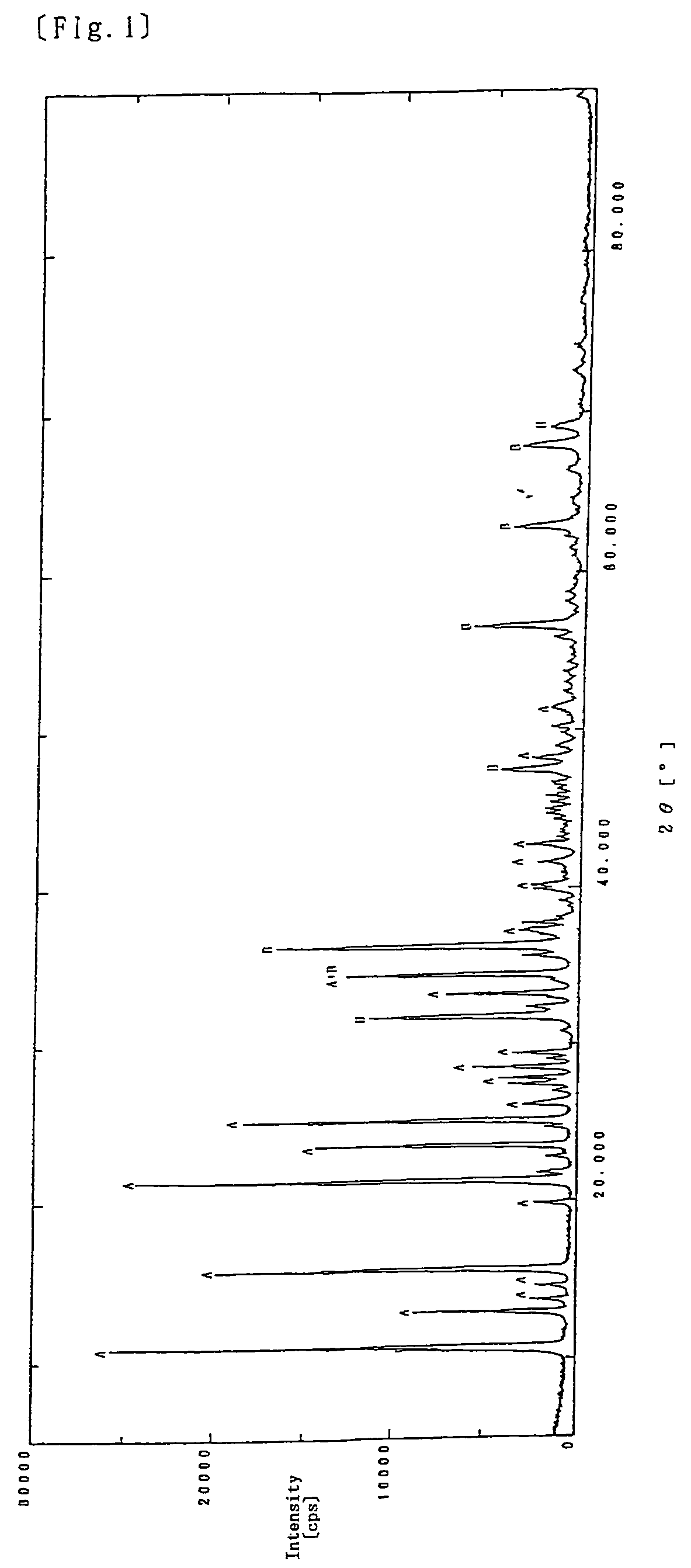

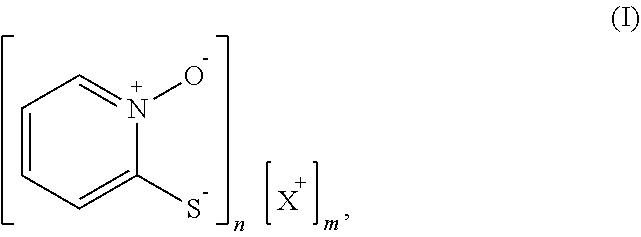

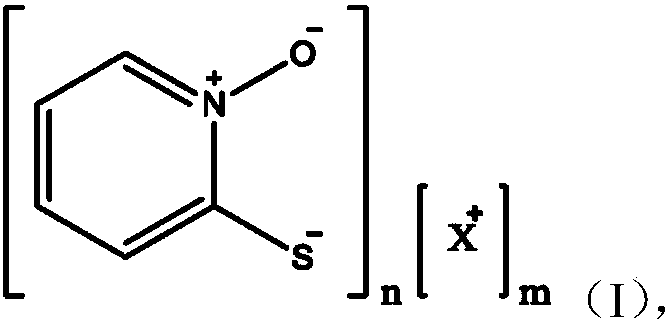

Novel pyrithione complex compound, process for producing the same and use thereof

InactiveUS20060246097A1Good effectReduced effectCosmetic preparationsBiocideSolubilitySodium Pyrithione

Zinc pyrithione and copper pyrithione are highly evaluated in the market as an antidandruff agent for shampoo, or an antifouling agent for ship bottom paint and fish-farming net, or an antibacterial / antifungal agent or preservative / mildewcide for industrial products and household articles. For enhancing the market value thereof, there has been a demand for a product that not only attains an increase in conventional antibacterial / antifungal effects but also exhibits novel bioactive effects and that achieves improvement with respect to problems and drawbacks relating to properties, such as solubility in seawater, and stability, such as thermal stability and weather resistance, of polymer materials. There is provided a novel pyrithione complex compound obtained by converting the conventional pyrithione metal salt to a complex compound with an oxide or hydroxide of metal such as zinc, copper or aluminum. As compared with the conventional pyrithione metal salt, this complex compound exhibits superior antibacterial / antifungal effects, newly realizes a hair-regrowing effect and successfully attains improvement with respect to the solubility in seawater and thermal stability / weather resistance of polymer materials.

Owner:YHS

Pyrithione complex compound, process for producing the same and use thereof

InactiveUS7659397B2Good effectGood antibacterial and antifungal effectBiocideCosmetic preparationsSodium PyrithioneSolubility

Owner:YHS

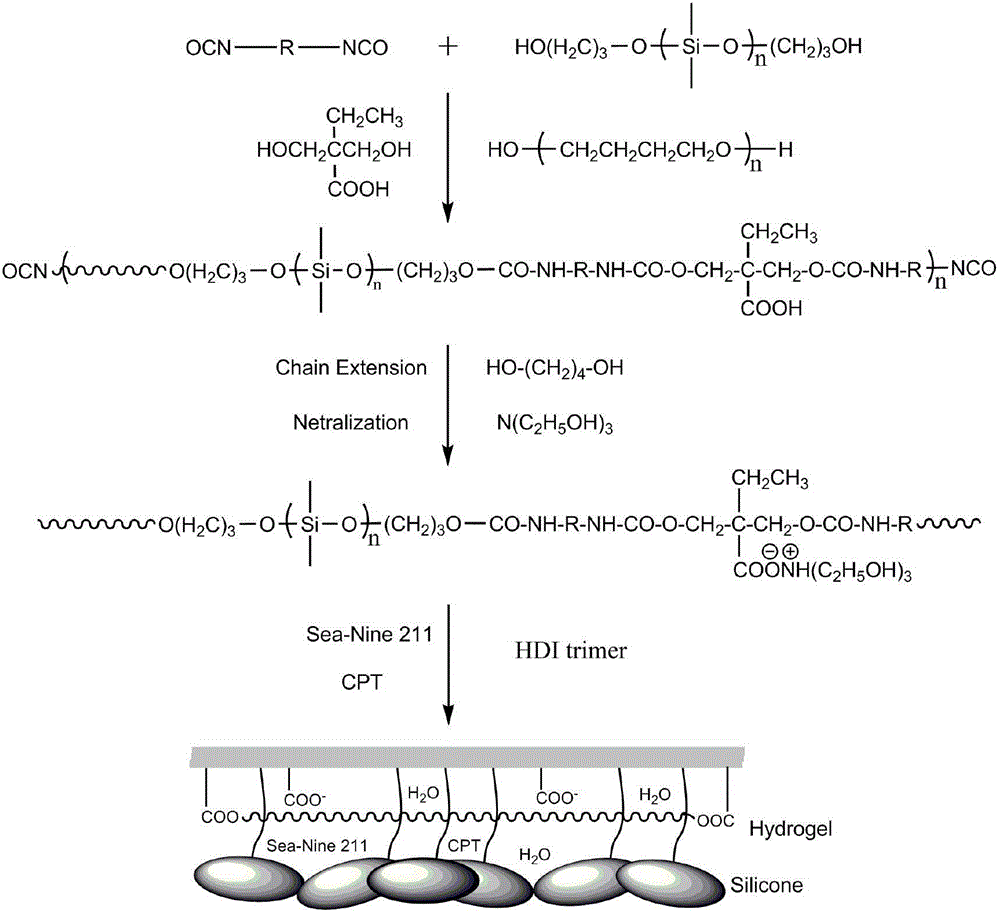

Preparation method of organosilicon-modified polyurethane hydrogel antifouling paint

ActiveCN105273600ASelf-layeringHas a self-healing effectAntifouling/underwater paintsPaints with biocidesSodium BentoniteCopper pyrithione

The invention relates to a preparation method of an organosilicon-modified polyurethane hydrogel antifouling paint. The method comprises the following steps: organosilicon-modified polyurethane resin is synthesized; and the hydrogel antifouling paint is prepared. The antifouling paint is a double-component paint composed of a component A and a component B with a mass ratio of (11-13):1. The component A is a resin binder carrier comprising the components of, by mass, 55-65 parts of organosilicon-modified polyurethane resin, 4-6 parts of red iron oxide, 0.5-1.5 parts of organic bentonite, 4-6 parts of zinc oxide, 7-9 parts of copper pyrithione, 6-8 parts of Sea-Nine 211, 2-3 parts of terminated dimethicone, and 10-11 parts of xylene. The component B is a crosslinking agent carrier. According to the invention, the organosilicon monomer is introduced into the polyurethane resin system with a chemical method; with appropriate auxiliary agents and antifouling agent, a low-surface organosilicon antifouling barrier layer is formed, and the paint is provided with self-layering and self-healing effects. The process is simple; the antifouling effect is good; anti-fouling agent dose is low; and production cost is greatly reduced.

Owner:ZHEJIANG MARINE DEV RES INST

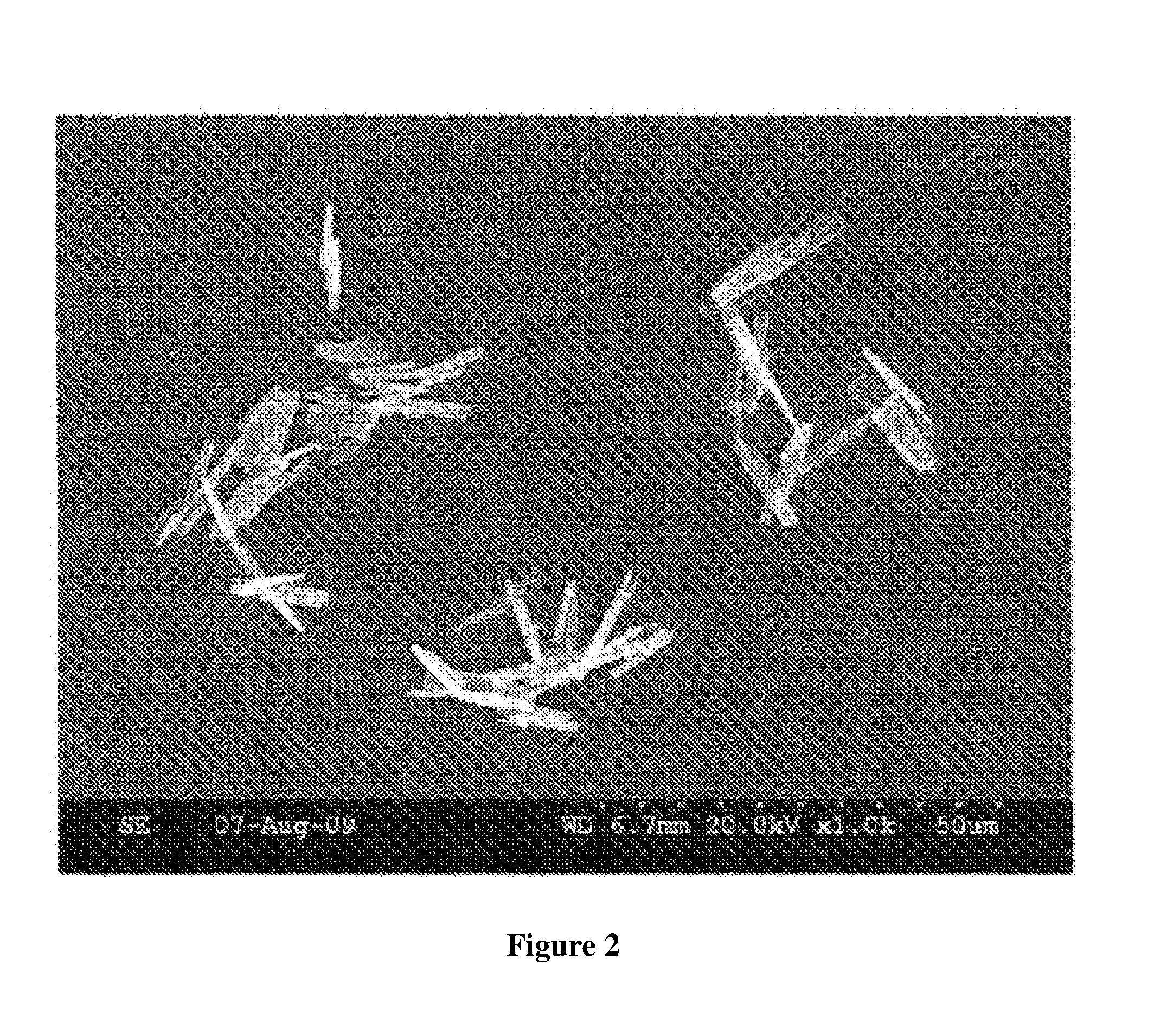

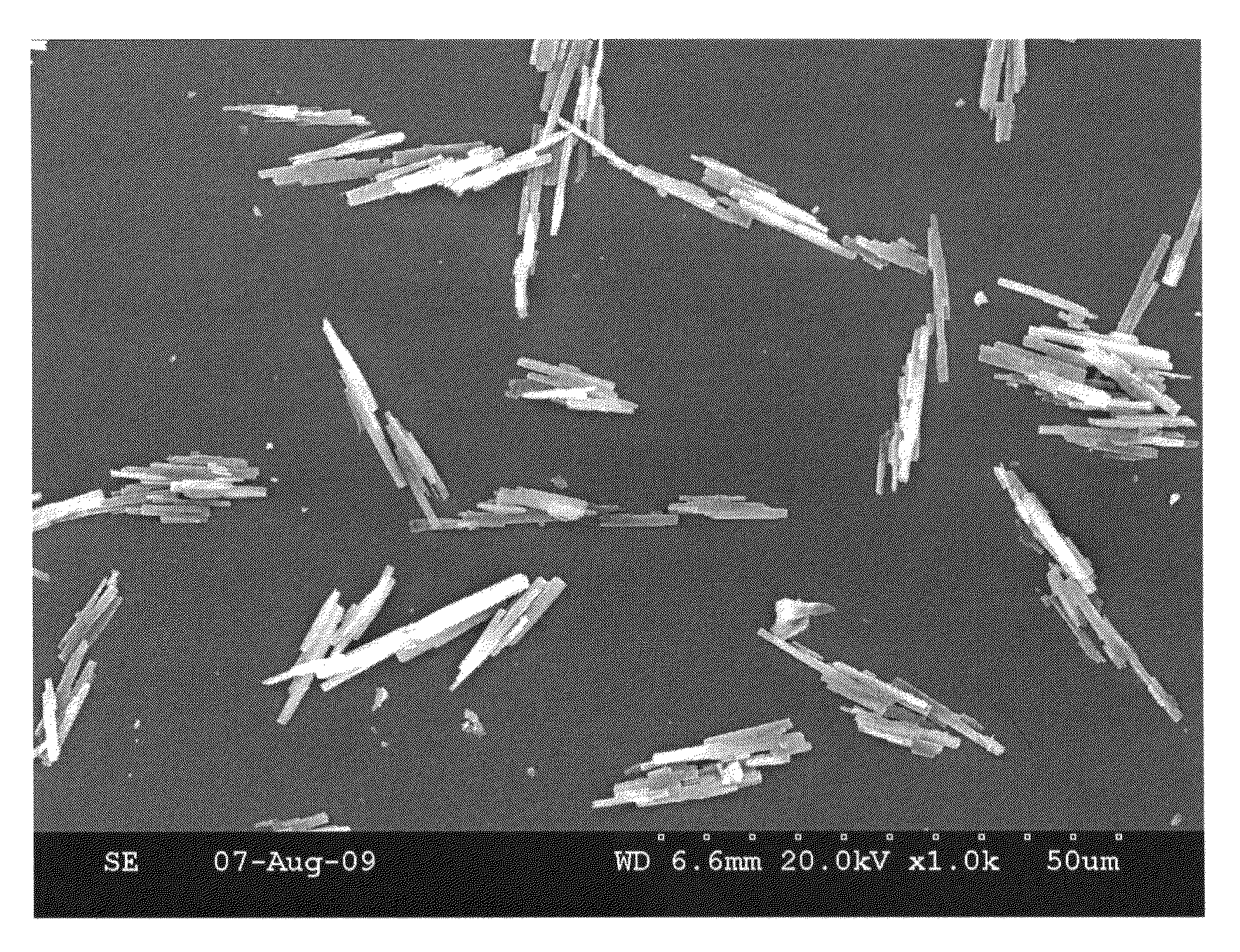

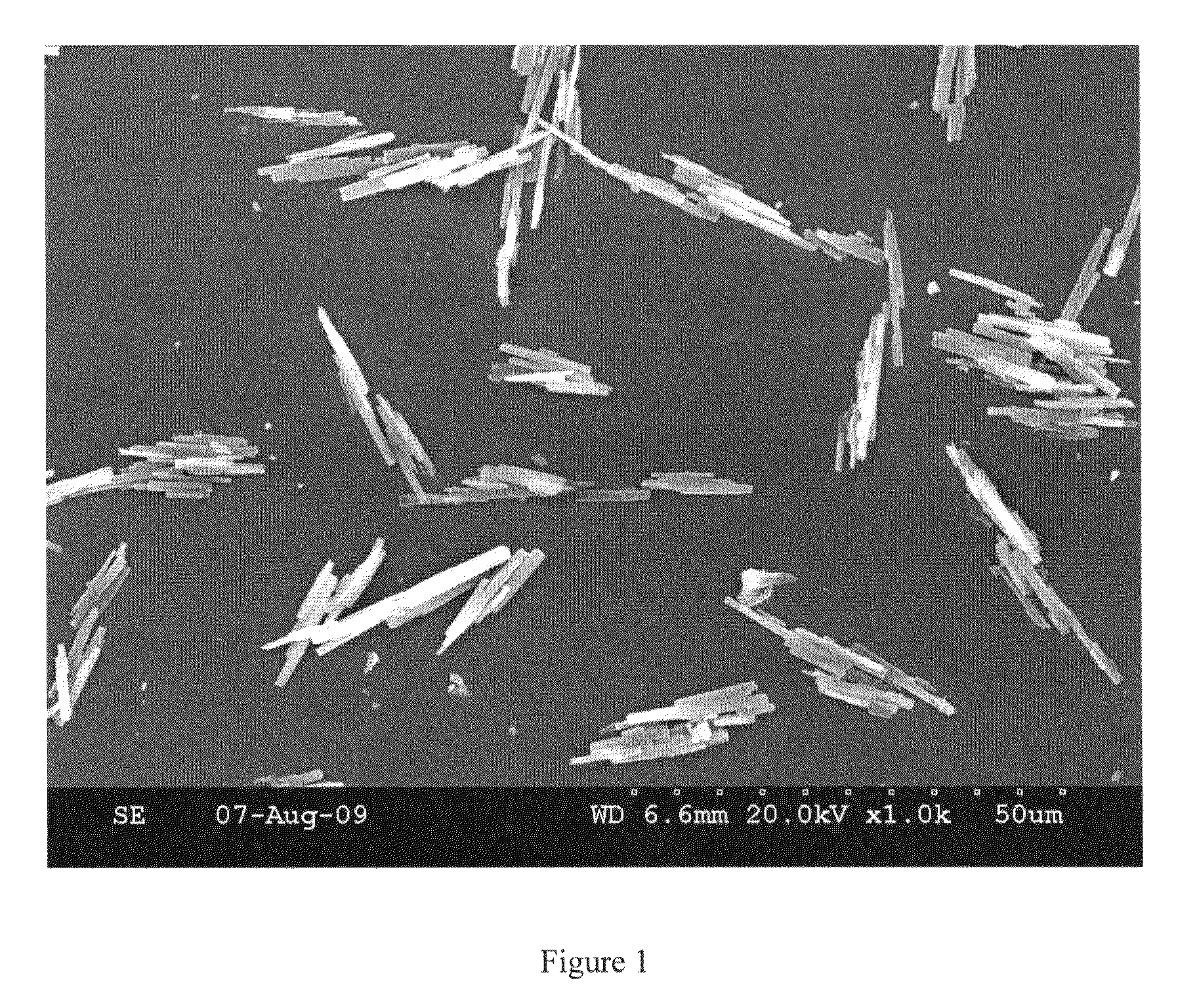

Synthesis of zinc acrylate copolymer from acid functional copolymer, zinc pyrithione, and copper compound

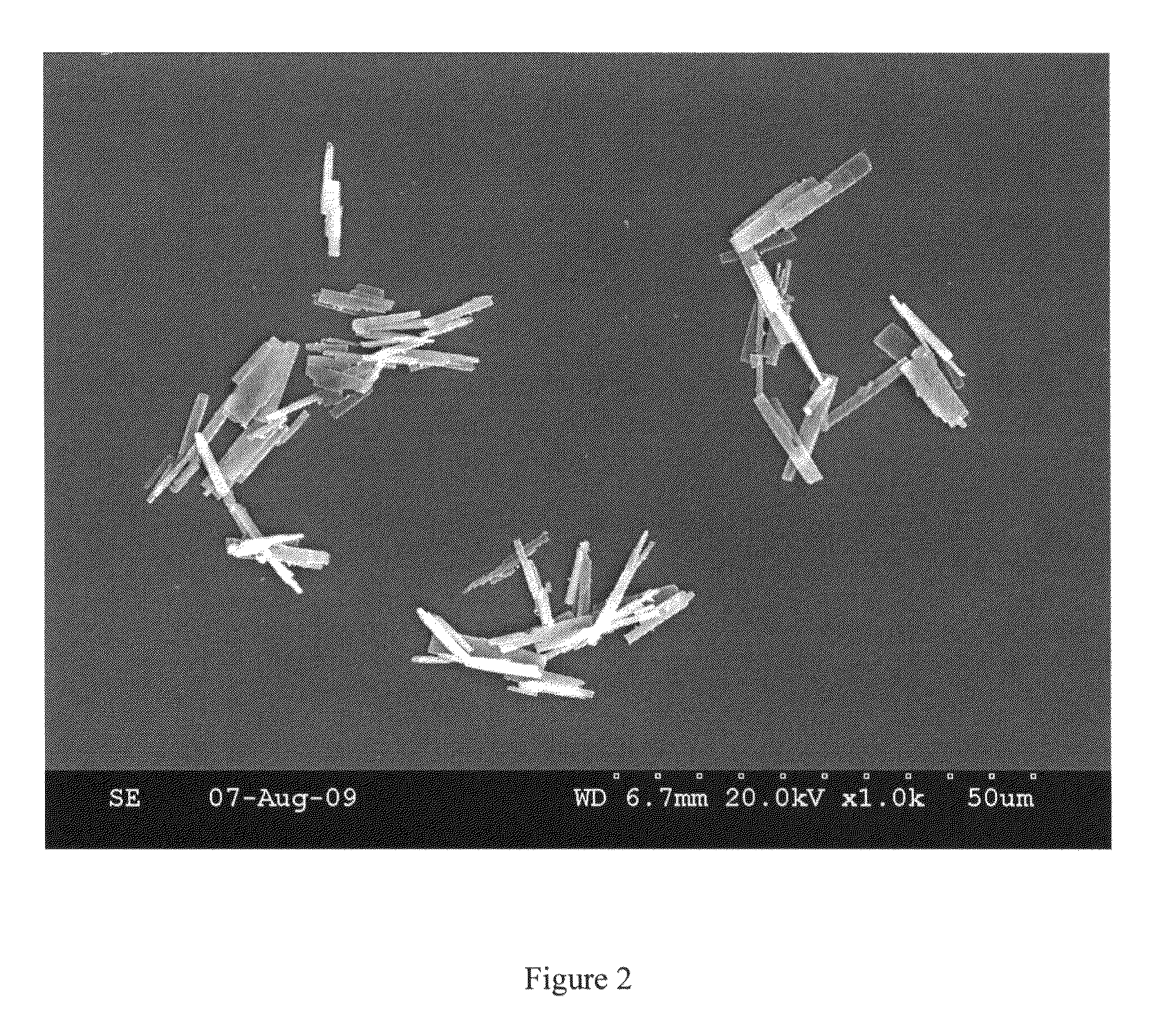

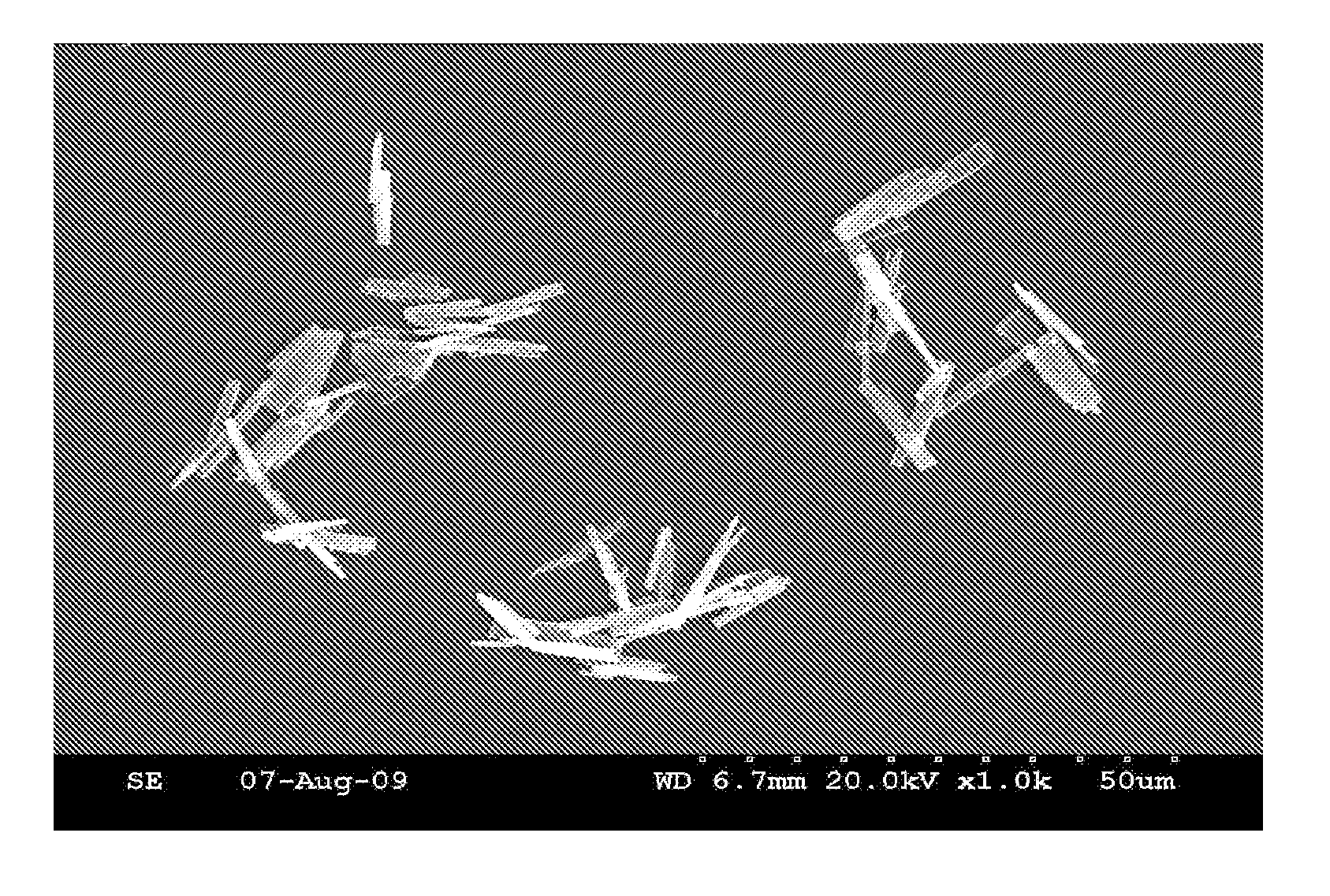

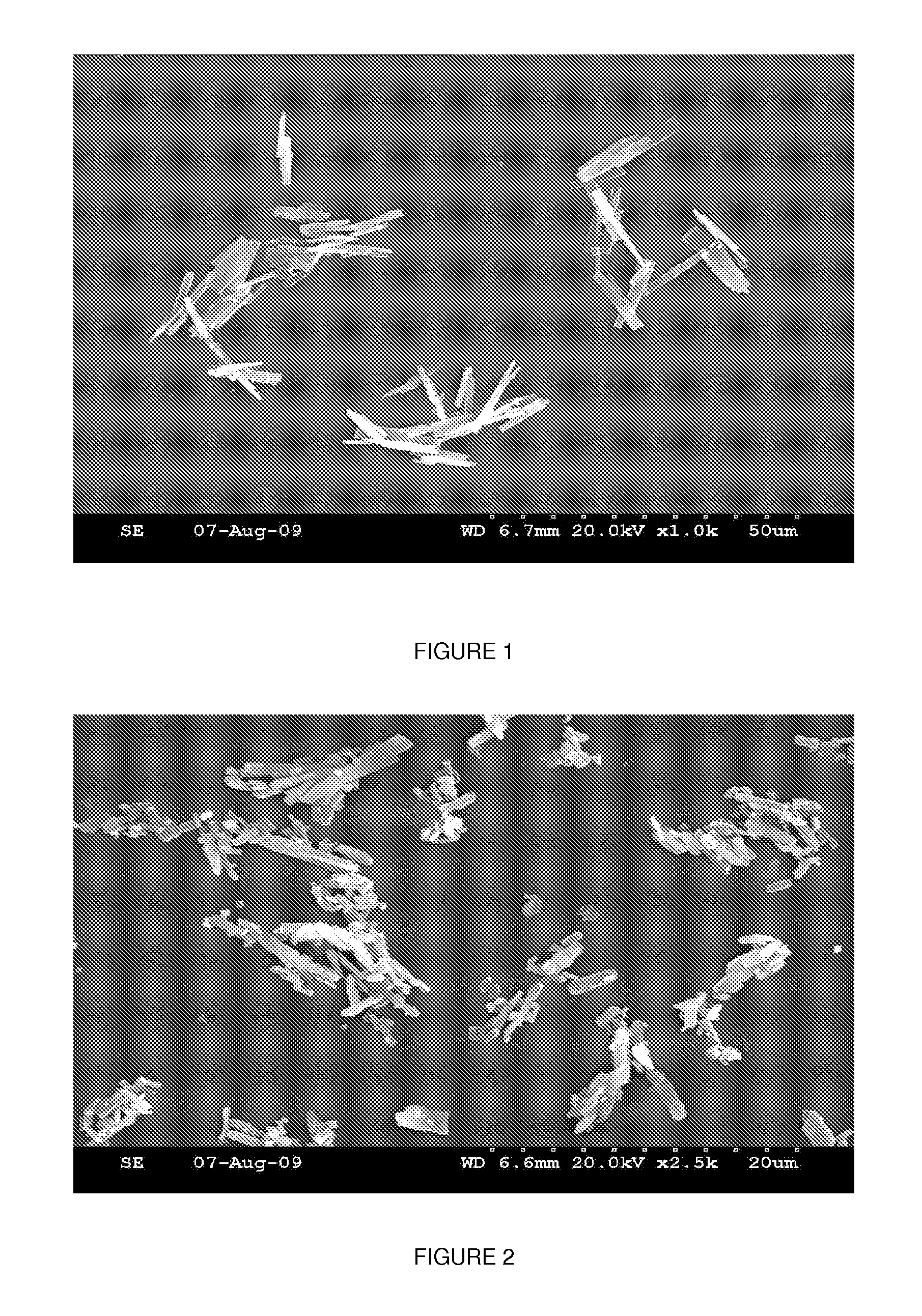

Disclosed is a composition containing zinc ester functional polymer and particulate copper pyrithione, wherein the particles have an average aspect ratio within a range of from about 8 to about 15, where the zinc ester functional polymer and the copper pyrithione are obtained by reacting an acid functional polymer with zinc pyrithione and a copper salt or a copper carboxylate. Also disclosed is an antifouling coating containing such a composition.

Owner:ARCH CHEM INC

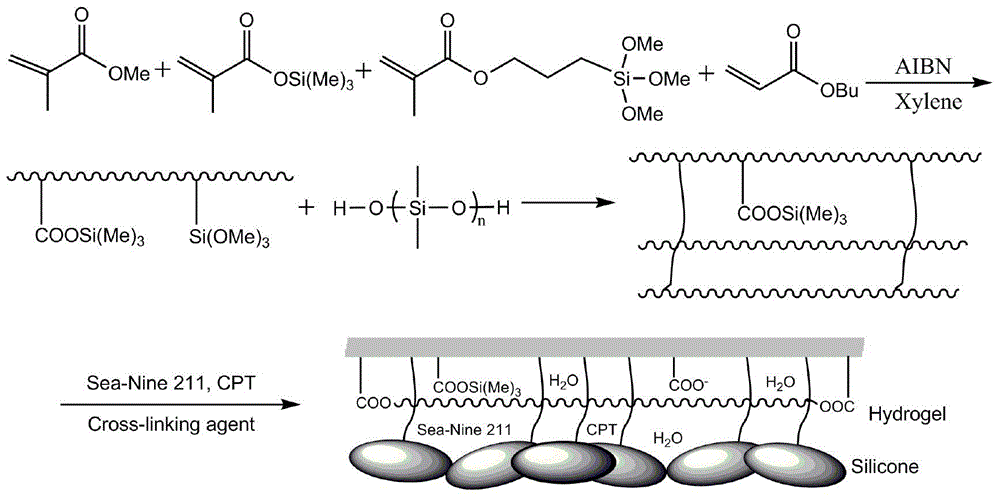

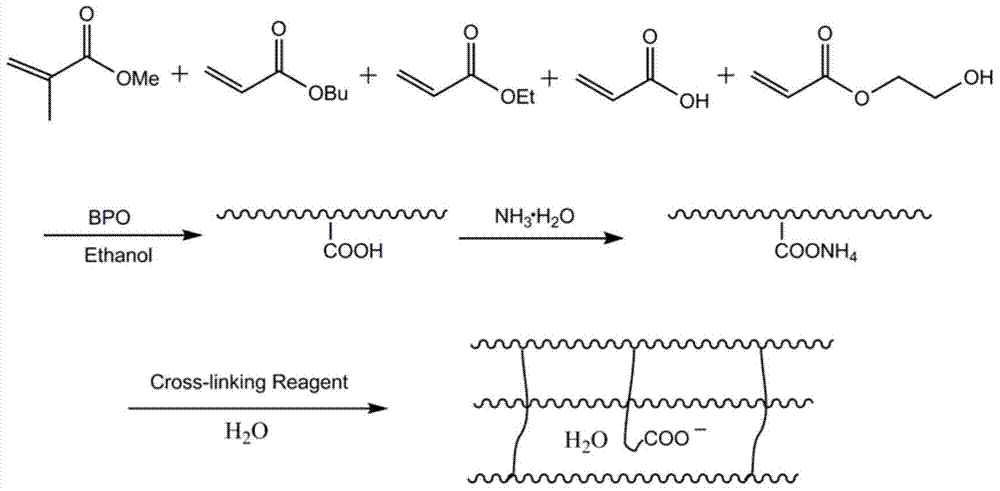

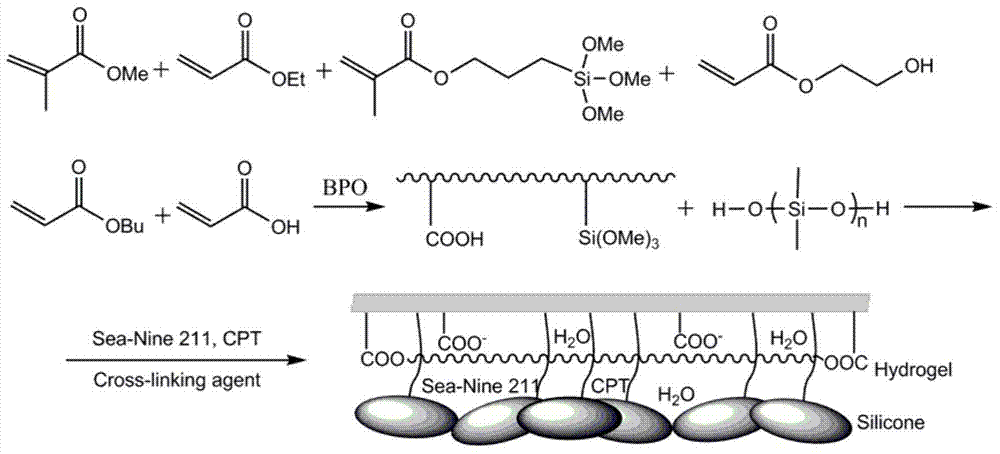

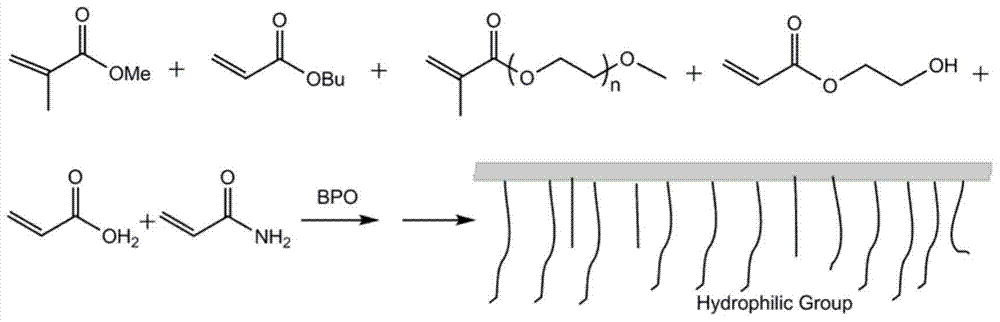

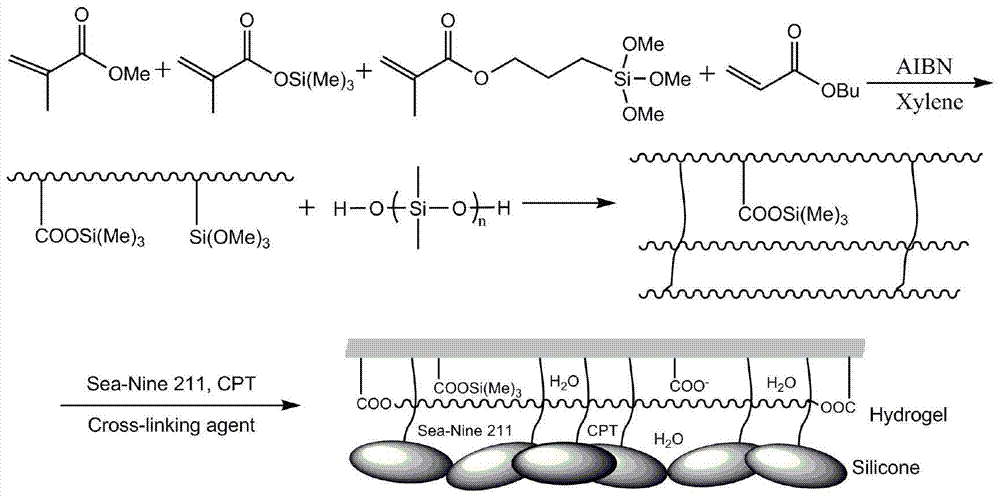

Preparation method of silicone modified acrylic hydrogel antifouling coating

ActiveCN105219206AImprove adhesionPrevent adhesionAntifouling/underwater paintsPaints with biocidesCross-linkAcrylic resin

A preparation method of a silicone modified acrylic hydrogel antifouling coating comprises the following steps: synthesizing silicone modified acrylic resin, and preparing the hydrogel antifouling coating. The antifouling coating is a double-component coating composed of a component A and a component B, and a mass ratio of the component A to the component B is 8:1, wherein the component A is a resin base material carrier, and comprises, by mass, 55-65 parts of the silicone modified acrylic resin, 4-6 parts of iron oxide red, 0.5-1.5 parts of organic bentonite, 4-6 parts of zinc oxide, 7-9 parts of copper pyrithione, 8-10 parts of a Sea-Nine211 antifouling agent and 10-12 parts of an organic solvent; and the component B is a cross-linking agent carrier, and comprises, by mass, 25-35 parts of an aziridine cross-linking agent, 60-70 parts of n-butanol and 4-6 parts of water. Silicone is introduced to the acrylic resin system through a chemical technology, and a proper assistant and the proper antifouling agent are matched to form a low-surface organosilicon antifouling barrier layer, so the coating has self-layering and self-restoration effects, simple process, good antifouling effect, small dosage of the antifouling agent, and effective prolongation of the antifouling time period.

Owner:舟山市知识产权促进会

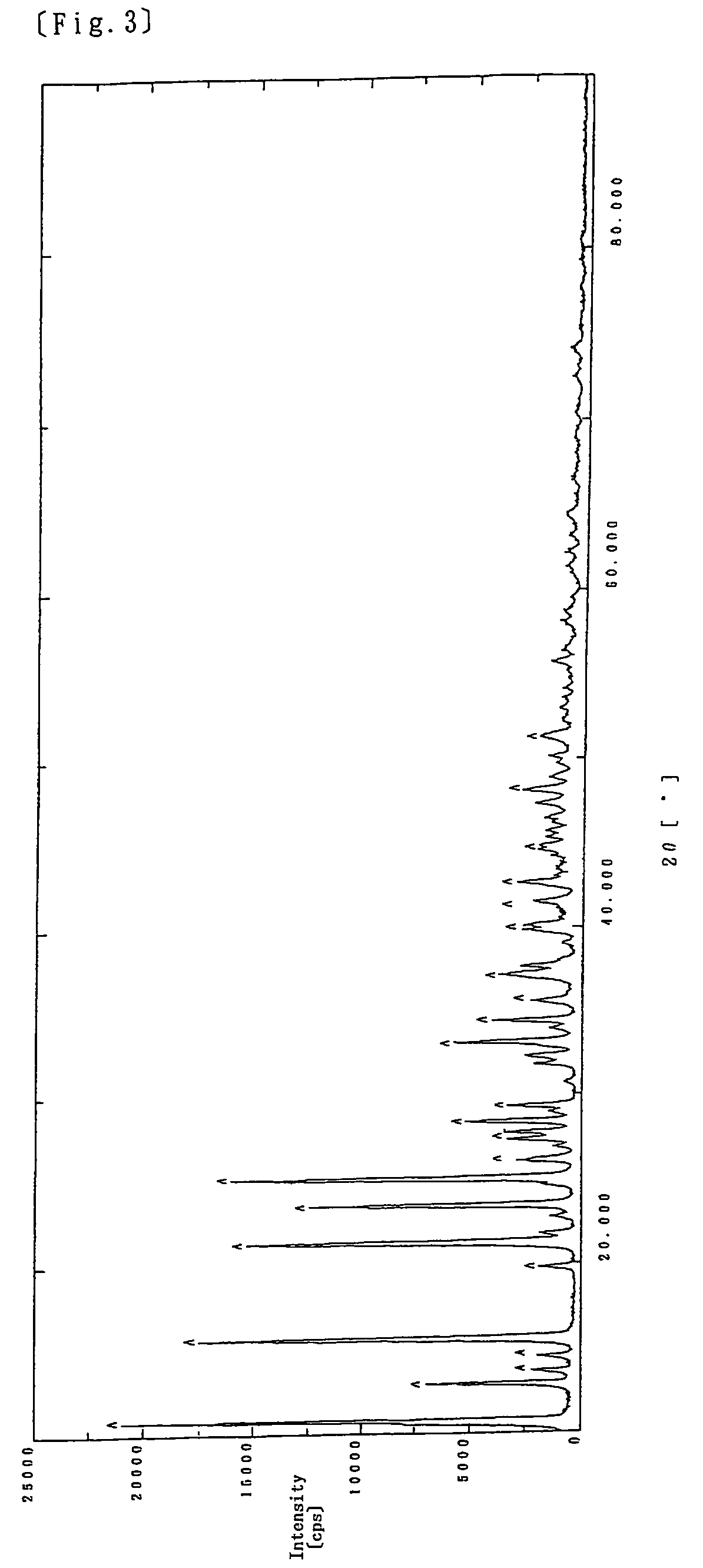

Synthesis method of copper pyrithione

ActiveCN102702094AReduce consumptionEasy to operateOrganic chemistryMolecular sieve catalystsChemical oxygen demandSynthesis methods

The invention relates to a synthesis method of copper pyrithione, which is characterized by comprising the following steps: (1) 2-chloropyridine oxidization: adding 2-chloropyridine and a catalyst into a container, and dropwisely adding hydrogen peroxide; (2) filtering the solution obtained in the step (1), carrying out vacuum drying on the filter cake, washing the filter cake, and carrying out vacuum drying on the filter cake again, wherein the obtained filter cake is the catalyst used in the step (1), and the filtrate is a 2-chloropyridine oxynitride solution; and (3) preparation of copper pyrithione. By using the synthesis method provided by the invention, the oxidization yield of 2-chloropyridine is enhanced from 80% to 98%, the total yield is enhanced from 75% to 93%, the product quality is enhanced from 95-96% to more than 98%, and the recycled catalyst can be used repeatedly; and thus, the raw material consumption is reduced, the production cost is lowered, the technological operation is simple, and the wastewater amount and COD (chemical oxygen demand) are obviously reduced.

Owner:NANTONG ACETIC ACID CHEM

Synthesis of zinc acrylate copolymer from acid functional copolymer, zinc pyrithione, and copper compound

Disclosed is a composition containing zinc ester functional polymer and particulate copper pyrithione, wherein the particles have an average aspect ratio within a range of from about 8 to about 15, where the zinc ester functional polymer and the copper pyrithione are obtained by reacting an acid functional polymer with zinc pyrithione and a copper salt or a copper carboxylate. Also disclosed is an antifouling coating containing such a composition.

Owner:ARCH CHEM INC

Composite biocidal particles

InactiveUS7942958B1Reducing inhibiting growthReduced skin absorptionAntibacterial agentsBiocideSodium PyrithioneCopper pyrithione

A biocidal composition is disclosed comprising composite particles, each of the composite particles containing a shell and a core, the core comprising a metal or a metal-containing compound wherein the metal is a moiety selected from the group consisting of zinc, copper, bismuth, silver, zirconium, and combinations thereof, the shell comprising a pyrithione adduct comprising the reaction product of pyrithione with a portion of the core metal or metal compound. In one aspect, an anti-fouling composition is disclosed comprising (a) an anti-soft-fouling effective amount of copper pyrithione; and (b) an anti-hard-fouling effective amount of a copper-containing salt, or oxide or hydroxide thereof. The present invention also relates to a method of making an antifouling composition comprising particles of copper pyrithione and a copper-containing salt that is effective against hard-fouling and soft-fouling organisms.

Owner:ARCH CHEM INC

Aqueous soft biomass anti-fouling paint and preparation method thereof

ActiveCN104293062AExtend the antifouling periodSave energyAntifouling/underwater paintsPaints with biocidesCross-linkSodium Pyrithione

The invention belongs to the technical field of marine protection and especially relates to an aqueous soft biomass anti-fouling paint and its preparation method. The aqueous soft biomass anti-fouling paint comprises dual components A and B, and mass ratio of the component A to the component B is 8-10: 1. The component A is a resin base-material carrier, and comprises the following ingredients, by weight, 60-66% of aqueous acrylic resin, 0-6% of iron oxide red, 5% of zinc oxide, 0-3% of active silica, 0-1% of organobentonite, 3-4% of zinc pyrithione, 3-4% of copper pyrithione, 9-10% of an antifouling agent, 5% of ethanol and 6% of water. The component B is a cross-linking agent. The formula adopted in the invention is nontoxic and harmless, and the anti-fouling paint obtained after mixing has a good antifouling effect.

Owner:舟山市知识产权促进会

Color antifouling paint without cuprous oxide and preparation thereof

InactiveCN101353493AHigh surface energyGood film formingRubber derivative coatingsAntifouling/underwater paintsCopper pyrithioneSolvent

The invention provides a colorized antifouling paint without cuprous oxide, which comprises the following components with the weight percentage of: 10-25 percent of resin, 1-2 percent of pigment, 14-33 percent of stuffing, 15-30 percent of antifouling agent, 5-10 percent of addition agent, and 10-25 percent of solvent, wherein, the antifouling agent comprises following components with the weight percentage of: 50-95 percent of cuprous thiocyanate, 3-35 percent of zineb, and 2-15 percent of copper pyrithione. The antifouling paint of the invention has no cuprous oxide, silicon or fluororesin; when the antifouling paint of the invention is applied to coating, various colors can be presented below a waterline of a vessel. The product is in accordance with requirements for environmental protection; the preparation method is simple; energy can be saved; the cost is low. The prepared antifouling paint has good film-forming performance under normal temperature; the storage stability and antifouling performance are excellent; attached organism can be killed effectively.

Owner:上海华谊精细化工有限公司上海开林造漆厂

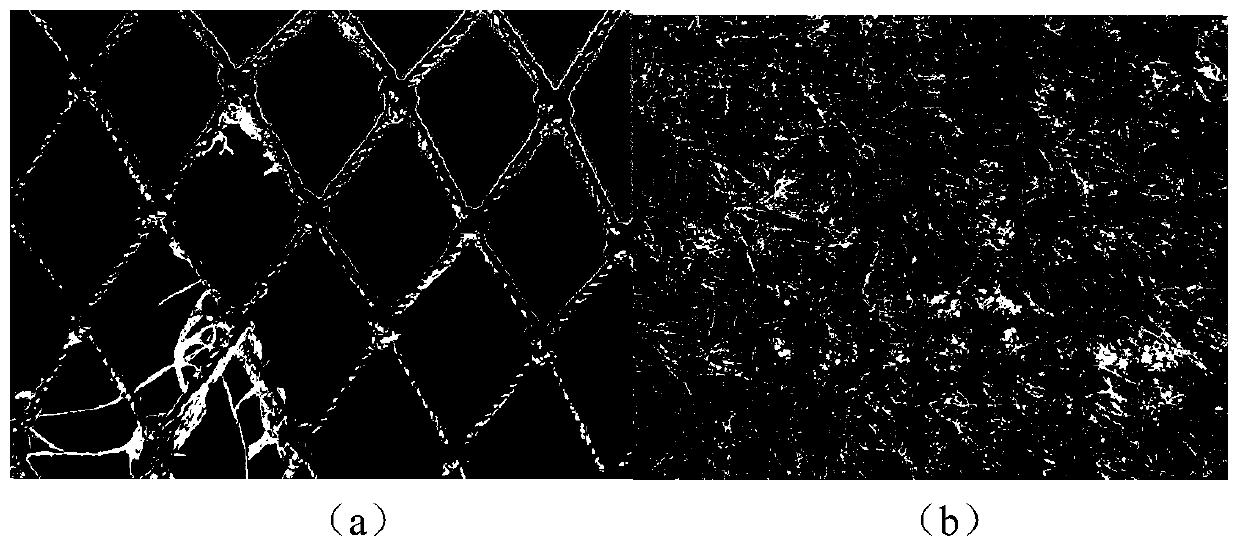

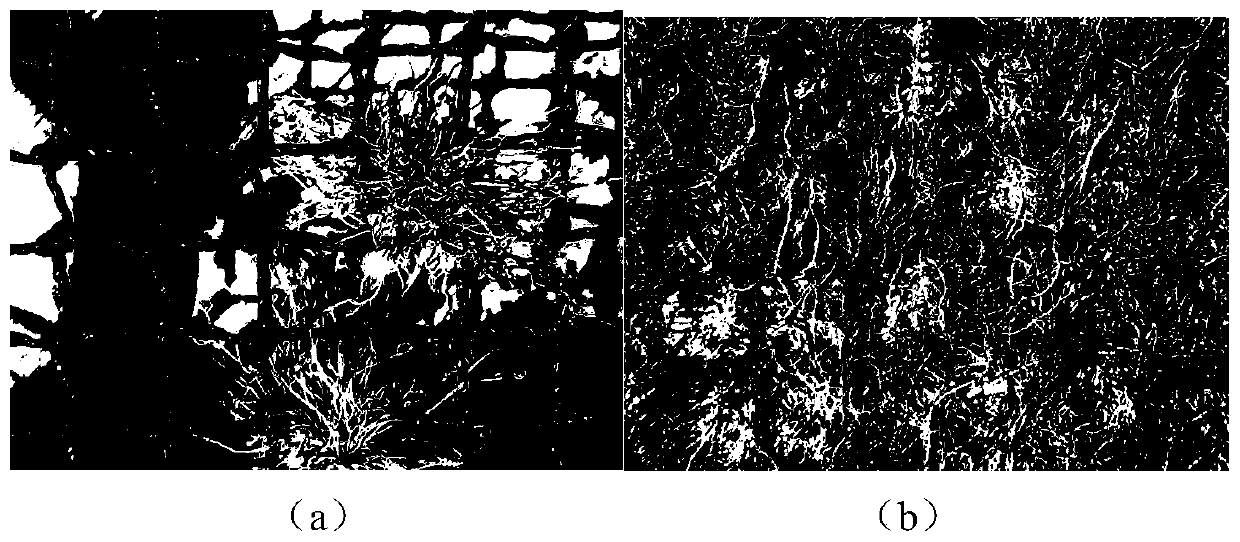

Antifouling coating for marine net wire and preparation method of antifouling coating

ActiveCN110724424AImprove adhesionGood weather resistanceAntifouling/underwater paintsPaints with biocidesThioketonePhosphate

The invention relates to the field of materials science, and discloses an antifouling coating for a marine net wire and a preparation method of the antifouling coating aiming at the problem of low flexibility and bactericidal activity of a matrix resin. The antifouling coating comprises the following components in percent by mass: 2-5% of modified nano zinc oxide, 2-7% of P-aminobenzoic acid, 2-7%of sodium benzoate, 2-7% of copper pyrithione, 2-7% of SeaNine211, 3-12% of oleamide, 0.5-2% of phytic acid, 2-6% of ZH 6900-20X, and the balance poly acrylic acid composite resin. A quaternary noveldiisobutylene / n-pentyl acrylate / styrene / isobornyl methacrylate copolymer resin is synthesized, the synthesized multi-polyethylene resin has excellent flexibility, and has good adhesion and weather resistance to a net wire, the anti-fouling ability is significantly improved, the environmental pollution and aquaculture maintenance cost are reduced, and the yield and quality of seafood aquaculture are relatively greatly improved.

Owner:ZHEJIANG OCEAN UNIV

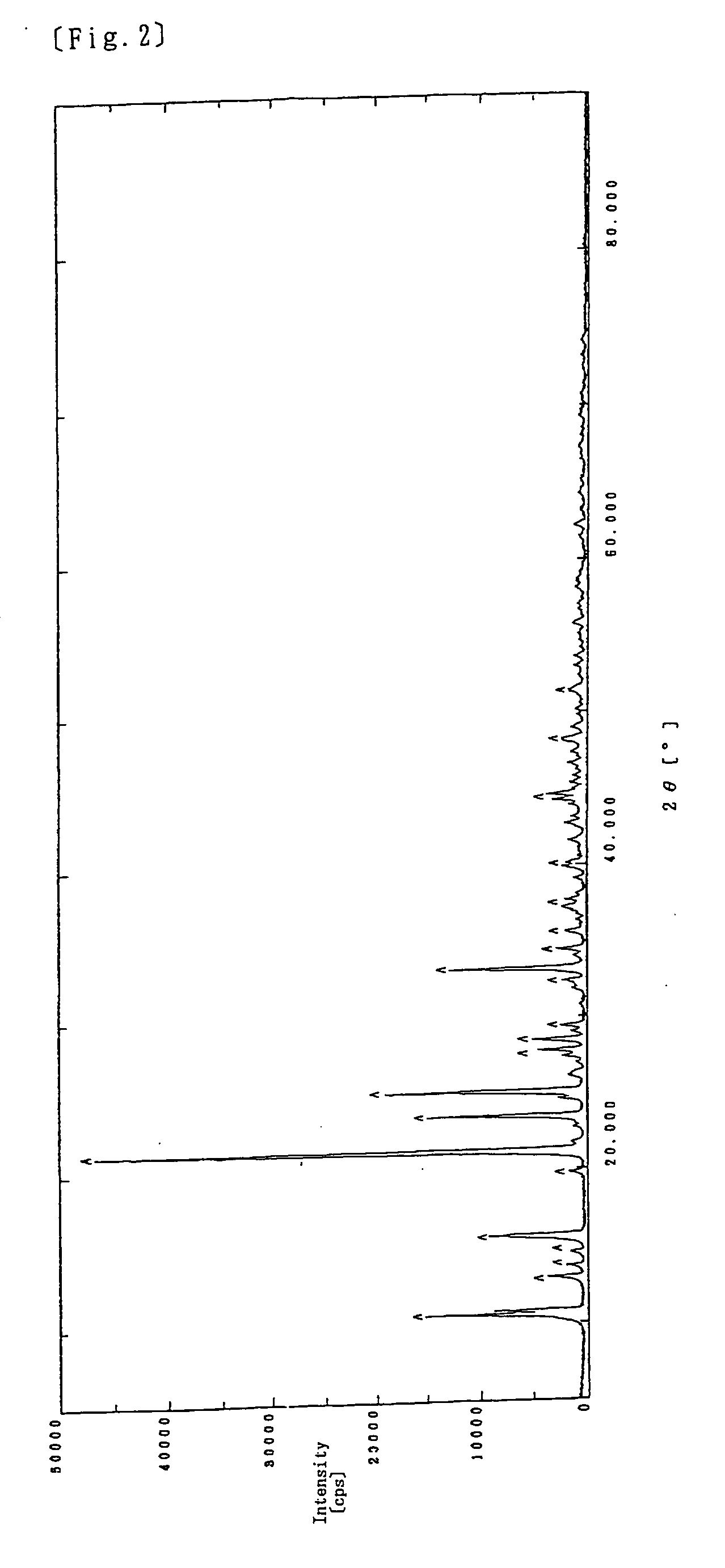

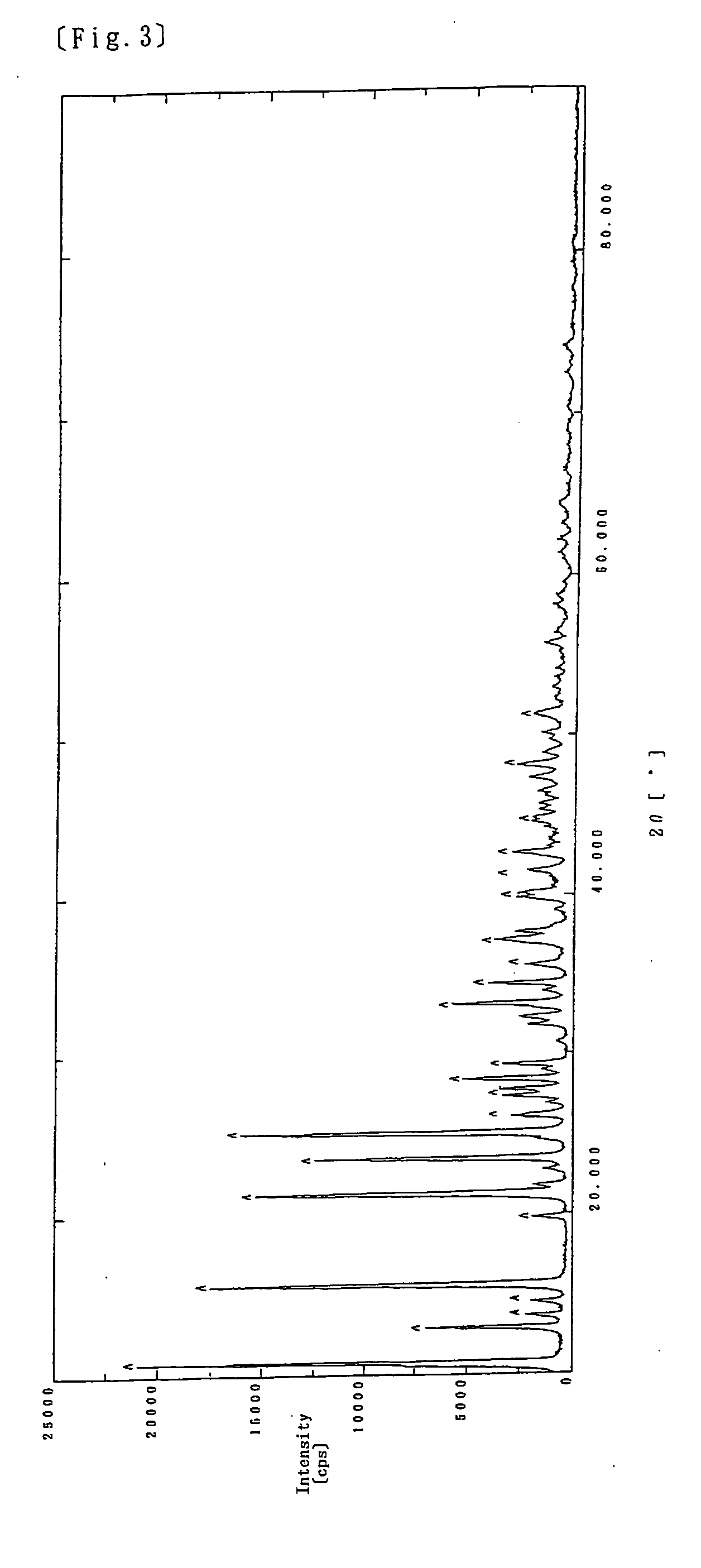

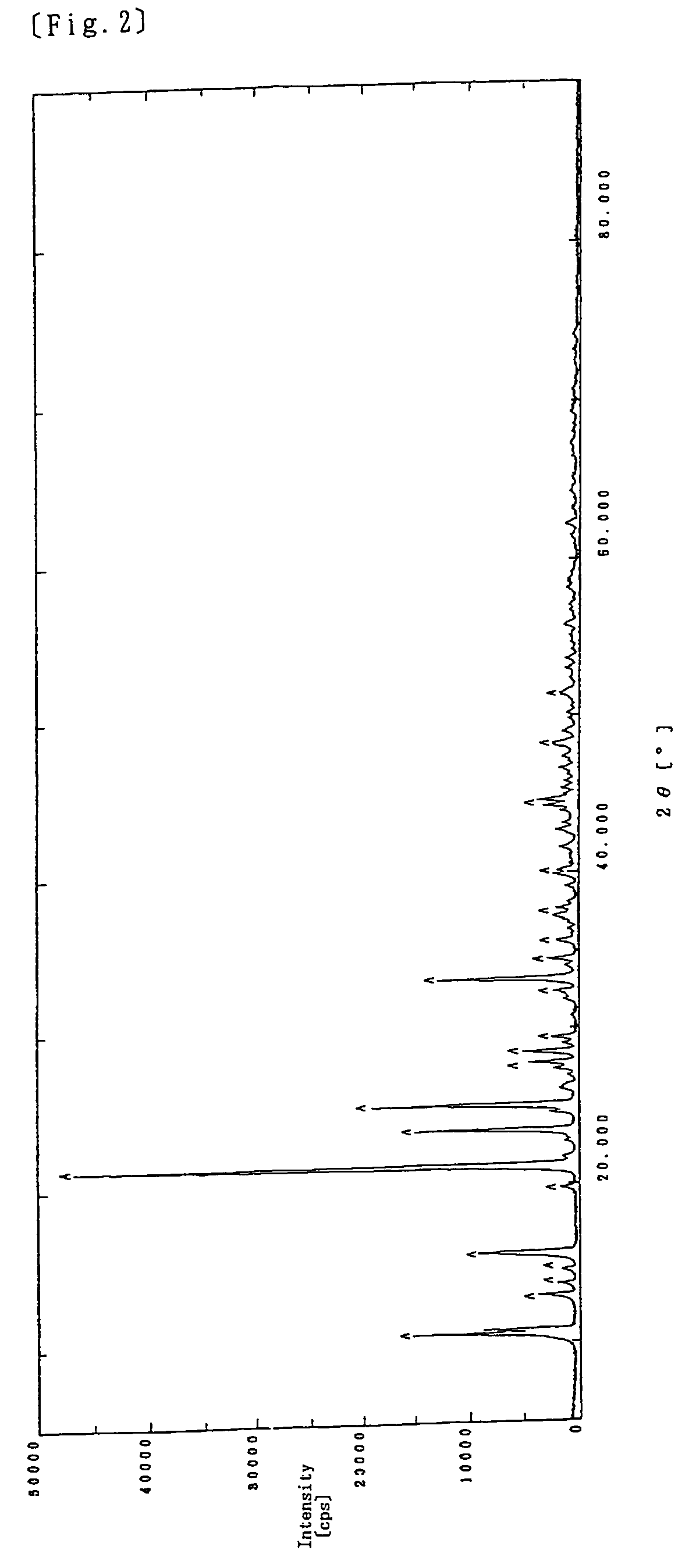

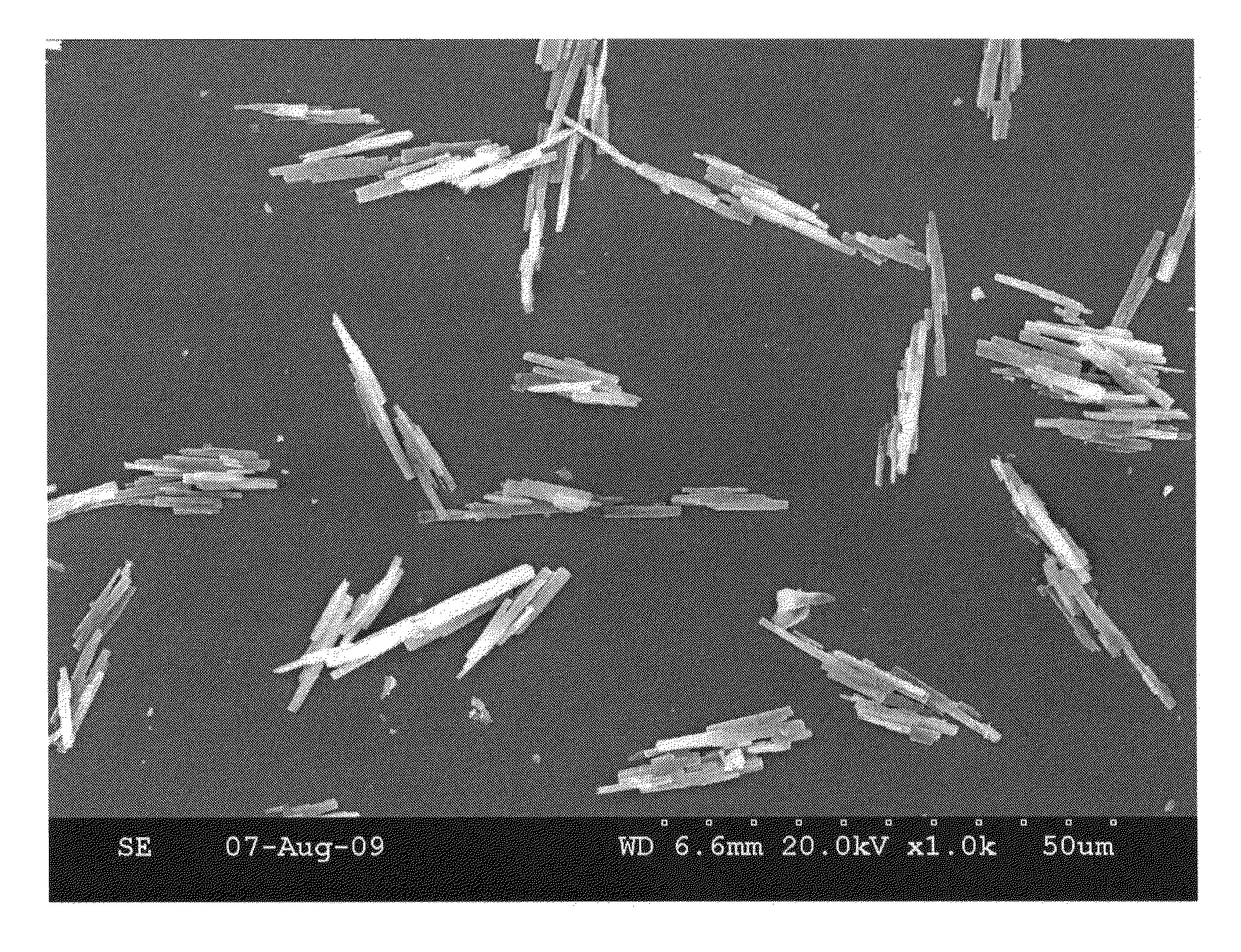

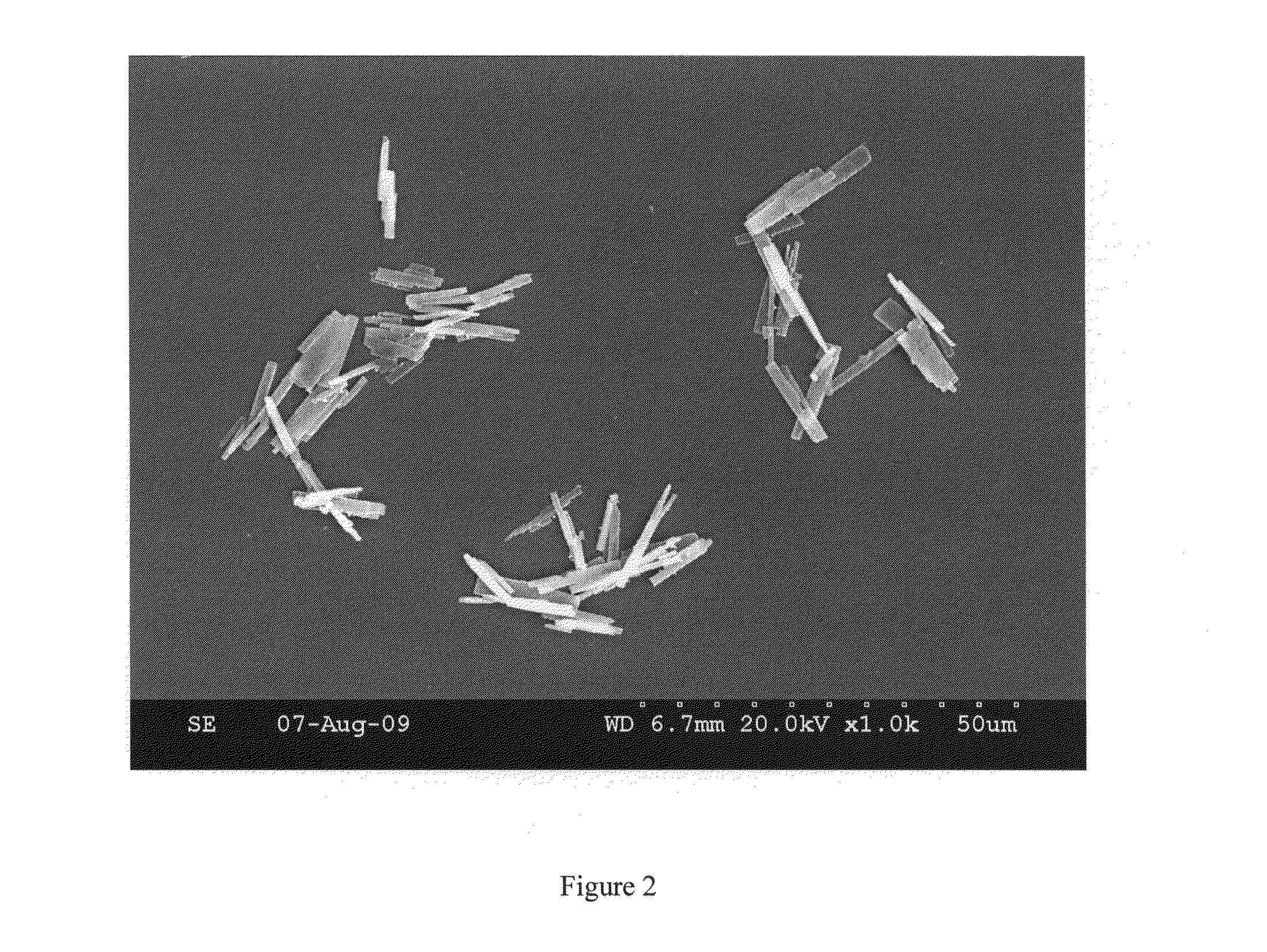

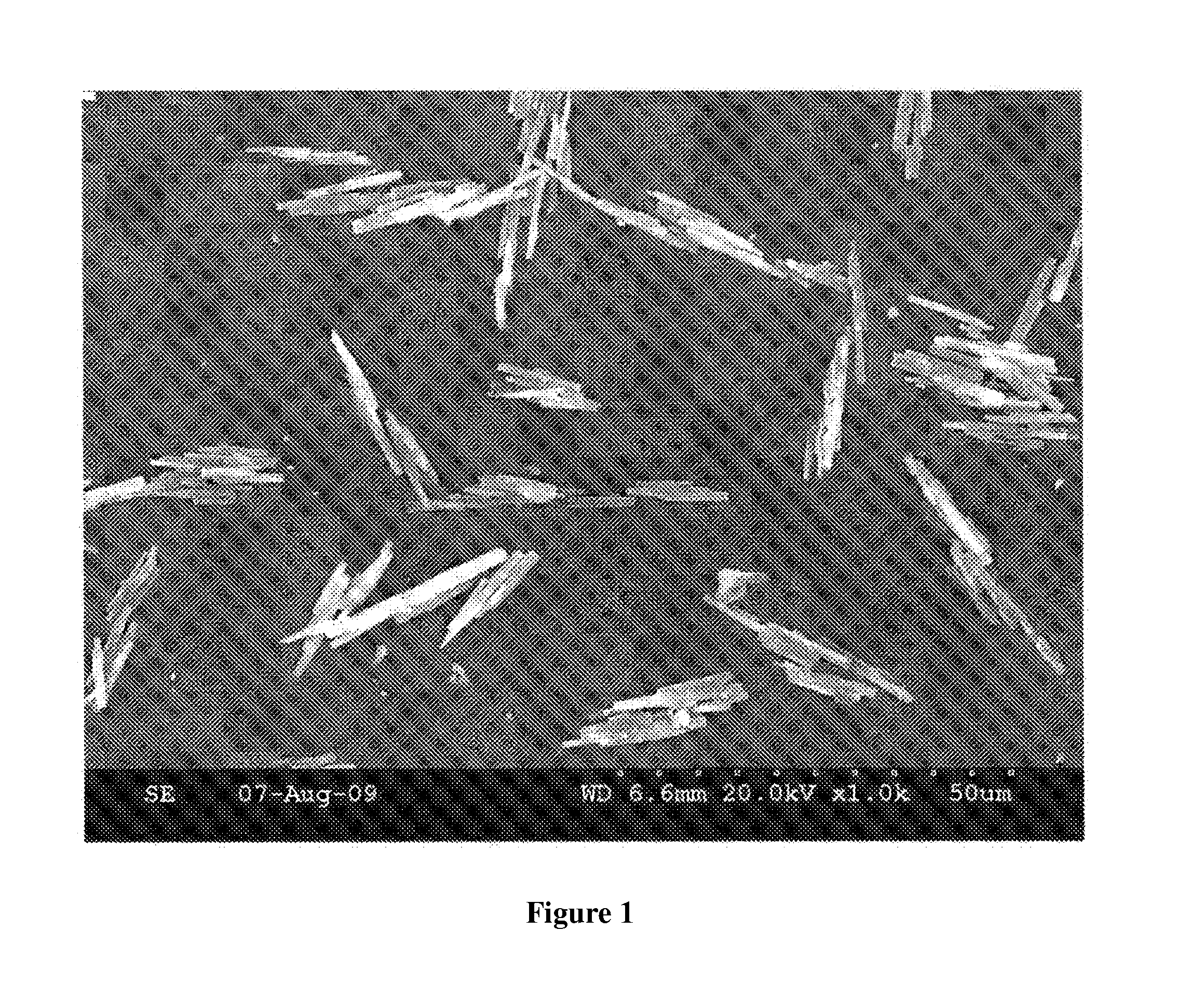

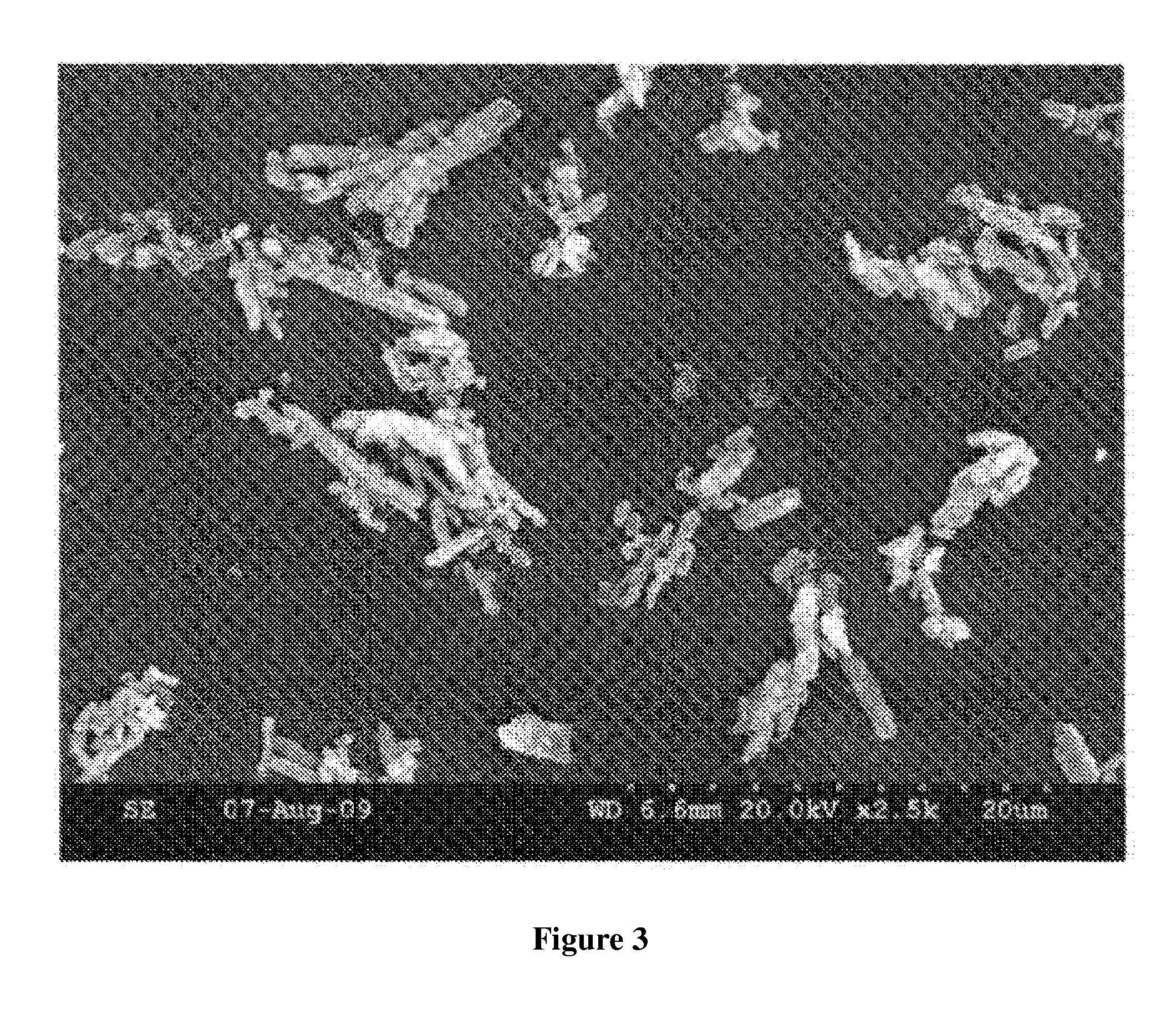

Small particle copper pyrithione

InactiveUS7481873B2Improve antibacterial propertiesGood curative effectFireproof paintsBiocideSodium PyrithioneSolid mass

Disclosed herein is a composition comprising a non-dusting copper pyrithione dispersion comprising small solid particles of copper pyrithione dispersed in a liquid dispersant, said solid particles having a particle size within a range of from about 0.1 to about 10 microns and a median particle size of from 0.2 to less than 0.5 microns. The dispersion is suitably employed as an antifouling additive for marine paints without risking worker exposure to copper pyrithione dust. Paints containing the small particle copper pyrithione exhibit improved antifouling performance in cold water, as compared to paint containing larger particle copper pyrithione.

Owner:ARCH CHEM INC

Anti-bacterial coating for glass surface and preparation method of anti-bacterial coating

InactiveCN108610719AExcellent adhesionGood coating effectAntifouling/underwater paintsPaints with biocidesCopper pyrithioneUltraviolet

The invention discloses an anti-bacterial coating for glass surface and a preparation method of the anti-bacterial coating, and relates to the field of glass coatings. The anti-bacterial coating comprises raw materials in parts by weight as follows: 30-40 parts of silicone emulsion, 1.5-2.5 parts of negative ion powder, 1-3 parts of zinc borate, 2-4 parts of copper pyrithione, 3-5 parts of silver-embedded nano titania, 3-5 parts of nano-zinc oxide, 4-7 parts of nano silica, 2-4 parts of a chitosan-copper complex, 0.4-0.9 parts of a silane coupling agent, 0.7-1.2 parts of an antistatic agent, 0.4-0.9 parts of an ultraviolet absorbent, 0.1-0.4 parts of a dispersing agent and 0.2-0.6 parts of an antifoaming agent. Under the synergistic effect of the components, the coating has excellent adhesive force, coating performance and ageing resistance and outstanding antibacterial property, is not prone to pulverization or falling and can effectively inhibit breeding of surface bacteria.

Owner:合肥钢骨玻璃制品有限公司

Isothiazolinone biocides enhanced by zinc ions

Owner:ARCH CHEM INC

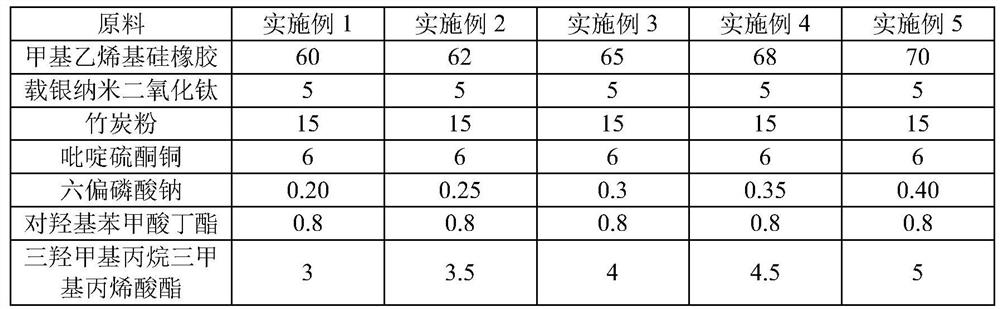

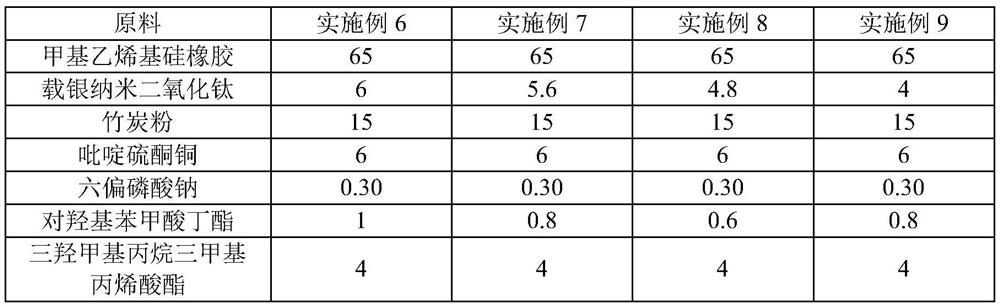

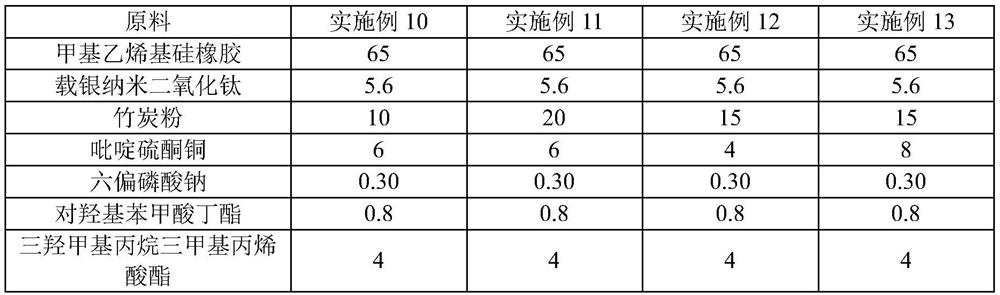

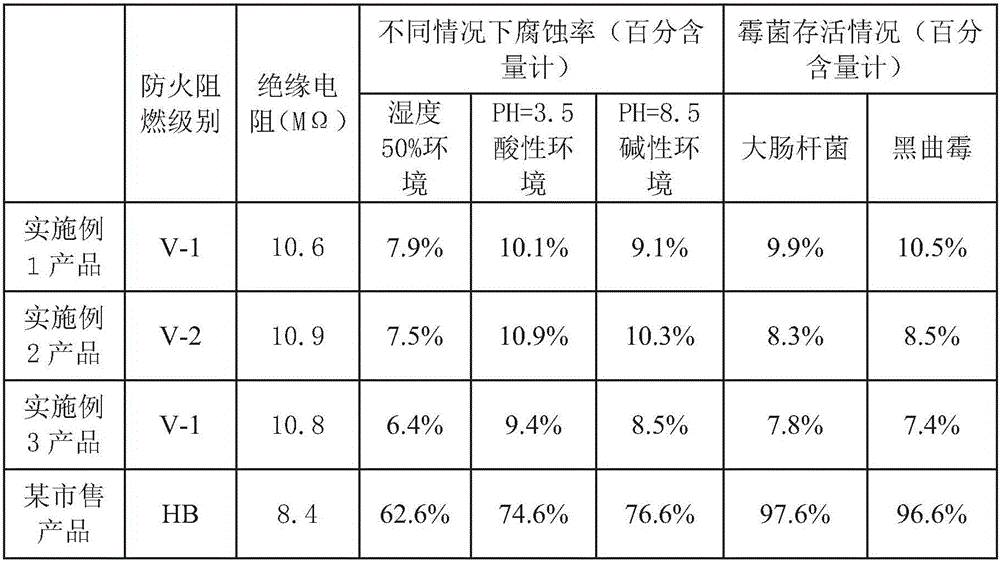

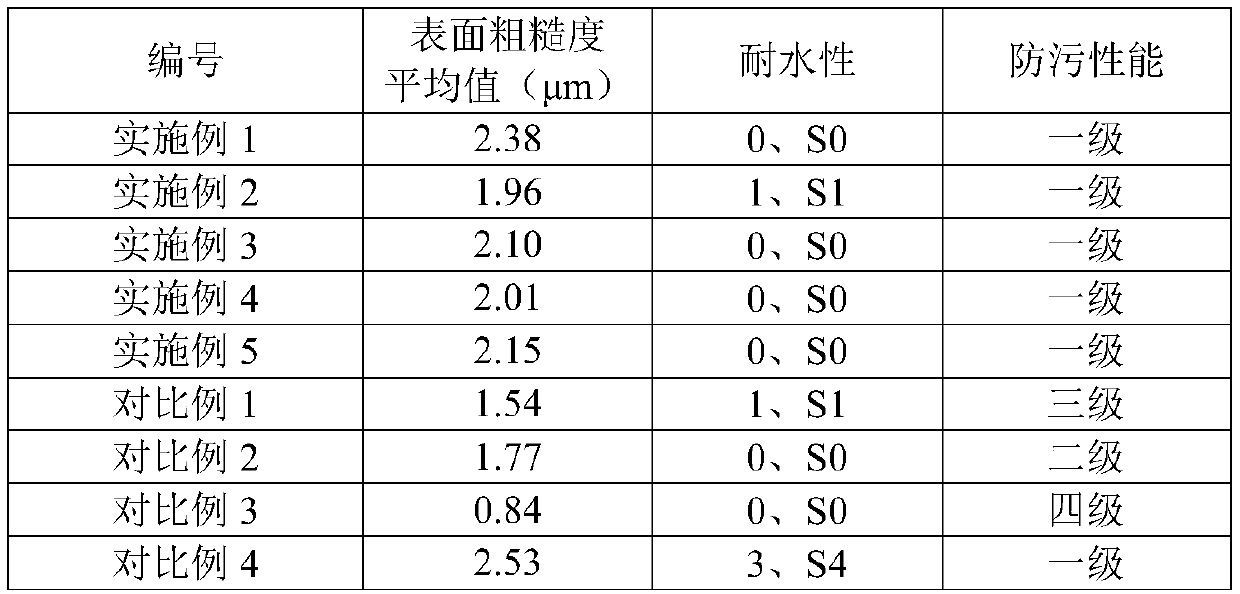

Mildew-proof antibacterial silicone rubber fabric and production process thereof

ActiveCN114316604AExcellent anti-mildew and anti-bacterial propertiesHigh tensile strengthLamination ancillary operationsSynthetic resin layered productsPolymer scienceSodium phosphates

The invention relates to the technical field of textile fabrics, and particularly discloses a mildew-proof and antibacterial silicone rubber fabric and a production process thereof. The high-temperature-resistant silicone rubber material is prepared from the following raw materials in parts by weight: 60 to 70 parts of methyl vinyl silicone rubber, 4 to 6 parts of silver-loaded nano titanium dioxide, 10 to 20 parts of bamboo charcoal powder, 4 to 8 parts of copper pyrithione, 0.2 to 0.4 part of sodium hexametaphosphate, 0.6 to 1 part of butyl p-hydroxybenzoate and 3 to 5 parts of vulcanizing agent. The highest inhibition rate of escherichia coli and staphylococcus aureus of the silicone rubber fabric is 99.9%, and the silicone rubber fabric has a high antibacterial effect; meanwhile, the optimal mildew-proof grade of the silicone rubber fabric is 0 grade, mildew spots do not appear on the surface, and the silicone rubber fabric has good mildew-proof performance.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

Multifunctional PVC pipe for electric power construction

The invention relates to a multifunctional PVC pipe for electric power construction. The PVC pipe is composed of the following components: phenolic resin, diisopropanolamine, dicumyl peroxide, iodopropynyl butyl carbamate, cinnamaldehyde, isothiazolinone, tea polyphenol, sodium diacetate, montmorillonite powder, triazine resin, phenothiazine, zirconium silicate powder, linseed alkyd resin, polybutylene terephthalate, acrylamide, PVC resin powder, zinc phosphate, polyacrylic acid, titanium dioxide, cylindrin, arabinogalactan, propyl paraben, copper pyrithione, melamine cyanurate, vancomycin, cyclohexanone, lumisterin, zirconium dioxide powder, silicon carbide powder, kaolin, and linseed oil. The ingredients mentioned above are mixed together to form a novel composite toughened and enhanced system, the performance indexes such as toughness, rigidity, elastic modulus, and the like, are good; the anti-aging performance and using property of product are largely improved, and the anti-corrosion effect is good.

Owner:王义金

Small particle copper pyrithione

InactiveUS20050118134A1Improve antibacterial propertiesGood curative effectFireproof paintsBiocideCopper pyrithionePyrithione

Disclosed herein is a composition comprising a non-dusting copper pyrithione dispersion comprising small solid particles of copper pyrithione dispersed in a liquid dispersant, said solid particles having a particle size within a range of from about 0.1 to about 10 microns and a median particle size of from 0.2 to less than 0.5 microns. The dispersion is suitably employed as an antifouling additive for marine paints without risking worker exposure to copper pyrithione dust. Paints containing the small particle copper pyrithione exhibit improved antifouling performance in cold water, as compared to paint containing larger particle copper pyrithione.

Owner:ARCH CHEM INC

Surface micro-structure self-polishing antifouling coating and preparation method thereof

InactiveCN110684421AImprove water resistanceImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesCopper pyrithioneThioketone

The invention relates to the technical field of ocean antifouling, aims to overcome the problems that a self-polishing antifouling coating has a large use amount of a cuprous oxide antifouling agent,a surface micro-structure is hard to apply to the surface of a vessel and a coating layer is damaged and the antifouling function is hard to take into play as ocean microorganisms and inorganic matterare settled to the surface, and provides a surface micro-structure self-polishing antifouling coating and a preparation method thereof. The surface micro-structure self-polishing antifouling coatingconsists of the following components in parts by weight: 20-30 parts of a resin, 1-3 parts of microgel spheres, 1-2 parts of a cross-linking agent, 2-3 parts of a plasticizer, 4-5 parts of cuprous oxide, 2-3 parts of copper pyrithione, 5-8 parts of terpene and 5-8 parts of an organic solvent. By virtue of the synergetic antifouling function of the surface micro-structure and a self-polishing antifouling agent, the antifouling effect of the surface of the coating layer can be improved, meanwhile, the use amount of an antifouling agent of a conventional self-polishing antifouling coating formulacan be greatly reduced, and the influence upon the ocean environment can be reduced.

Owner:ZHEJIANG MARINE DEV RES INST

Antimicrobial paint composition and related methods

An antimicrobial paint composition for forming an antimicrobial coating is disclosed. The antimicrobial paint composition comprises a carrier vehicle, a film-forming polymer, a glass comprising copper, and a non-copper pyrithione salt. A method of preparing the antimicrobial coating on an indoor surface with the antimicrobial paint composition is further disclosed. The method comprises applying the antimicrobial paint composition on the indoor surface and forming the antimicrobial coating on the indoor surface from the antimicrobial paint composition.

Owner:BEHR PROCESS

Preparation method of polyethylene net thread monofilament with marine fouling prevention property

ActiveCN110685032AWith micro-nano structured surfaceHigh strengthMonocomponent polyolefin artificial filamentArtifical filament manufactureMicro nanoHigh density

The invention relates to the field of material science, discloses a preparation method of a polyethylene net thread monofilament with marine fouling prevention property, and aims at the problems of coating peeling and high maintenance cost in the prior art. The net thread monofilament comprises, per 100 parts by weight, 2.3-3.8 parts of copper pyrithione, 2.2-3.5 parts of pyridine bromonitrile, 2.-3.2 parts of modified nano ZnO powder, 0.8-1.2 parts of zinc acrylate resin, and the balance of a mixture of high-density polyethylene particles and polypropylene powder. The five preparation steps mainly comprise drying, uniform mixing of materials, drawing, setting and solvent removing. According to the invention, an antifouling agent is directly added into the net thread monofilament, so thatnetting has better antifouling performance; the monofilament has a certain micro-nano structure surface and good wear resistance; subsequent complicated antifouling paint construction and environmental pollution are avoided; the maintenance of net threads during use is reduced, the monofilament preparation process is simple, and the processing cost is saved.

Owner:ZHEJIANG OCEAN UNIV

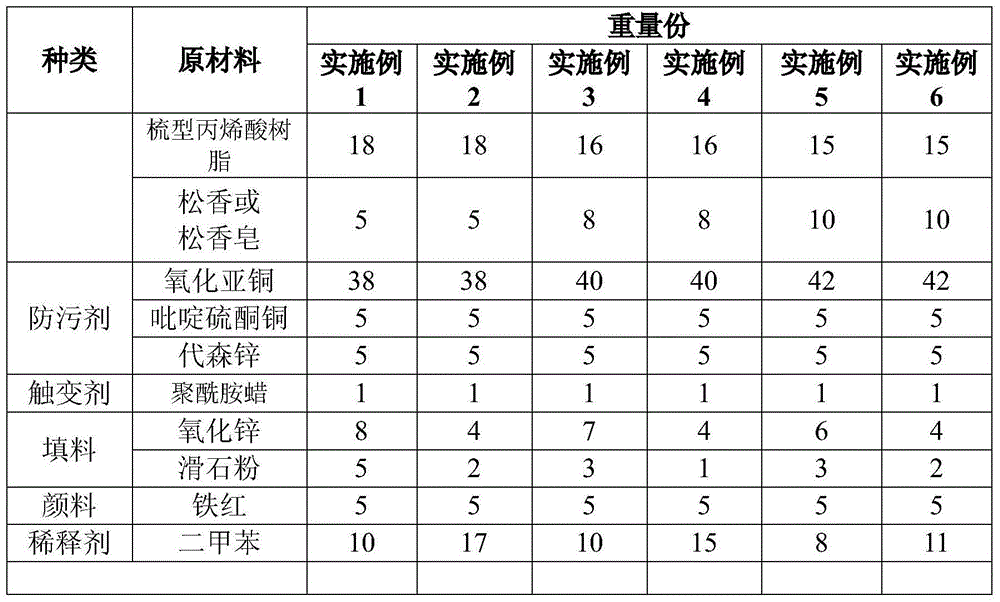

Preparation method of antifouling paint with high hydrolysis rate

InactiveCN104673093AGuaranteed safe operationAntifouling/underwater paintsRosin coatingsWaxCopper pyrithione

The invention relates to a preparation method of an antifouling paint with a high hydrolysis rate. The preparation method comprises the following steps: putting 15-18 parts by weight of combtype acrylic resin, 5-10 parts by weight of natural rosin or a rosin soap, 5-10 parts by weight of iron oxide red, 4-8 parts by weight of zinc oxide and 1-5 parts by weight of talcum powder together into 5-17 parts by weight of dimethylbenzene to be dissolved and dispersed; after fully dissolving, transferring the mixture obtained from the former step to a grinder to be ground to the grain size being less than 80 microns; then, transferring the ground material from the former step to a dispersing machine and adding 38-42 parts by weight of cuprous oxide, 5 parts of copper pyrithione and 5 parts of zineb to be dispersed and stirred; after uniformly dispersing and stirring, transferring the mixture from the former step to the grinder to be ground to the grain size being less than 100 microns; then transferring the ground material from the former step to the dispersing machine and adding 1 part by weight of polyamide wax to be dispersed and stirred; and after uniformly dispersing and stirring, preparing the antifouling paint with the high hydrolysis rate, wherein the copper ion exudation rate under a static condition can reach 30-40 microgram / (cm<2>.d), and the antifouling paint has an antifouling period of two years.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

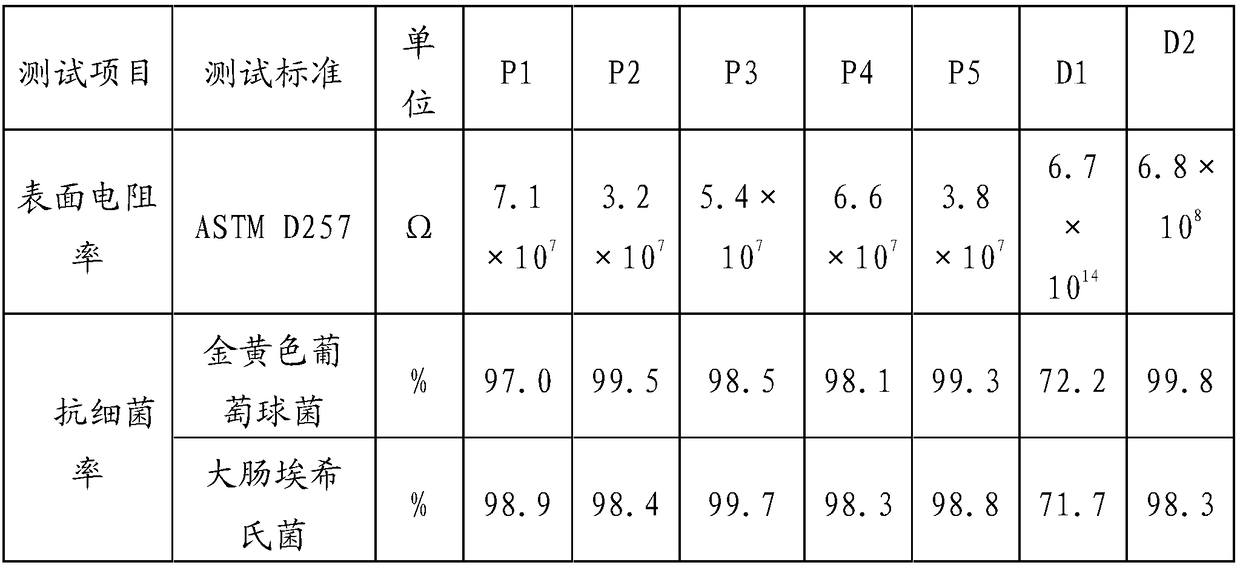

Anti-microbial antistatic PET composite material and preparation method thereof

The invention relates to an anti-microbial antistatic PET composite material and a preparation method thereof. The anti-microbial antistatic PET composite material comprises the following components in parts by weight: 80-100 parts of PET, 2-6 parts of antibacterial agent, 4-8 parts of antistatic agent and 0.1-0.5 part of antioxidant. A novel copper pyrithione loaded zeolite antibacterial agent iscompounded according to the technology and is capable of effectively improving the antibacterial property of a PET composite material; nanometer indium sesquioxide and polyvinyl alcohol are used as acompound antistatic agent, so that the surface resistivity of the PET composite material can be reduced; nanometer indium sesquioxide and polyvinyl alcohol are difficult to migrate, can permanently form a conductive path and can achieve an antistatic effect; compared with a single antistatic agent, the compound antistatic agent has a better effect; the defects of the present product are overcome;the anti-microbial antistatic PET composite material has ultrahigh promotional value.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

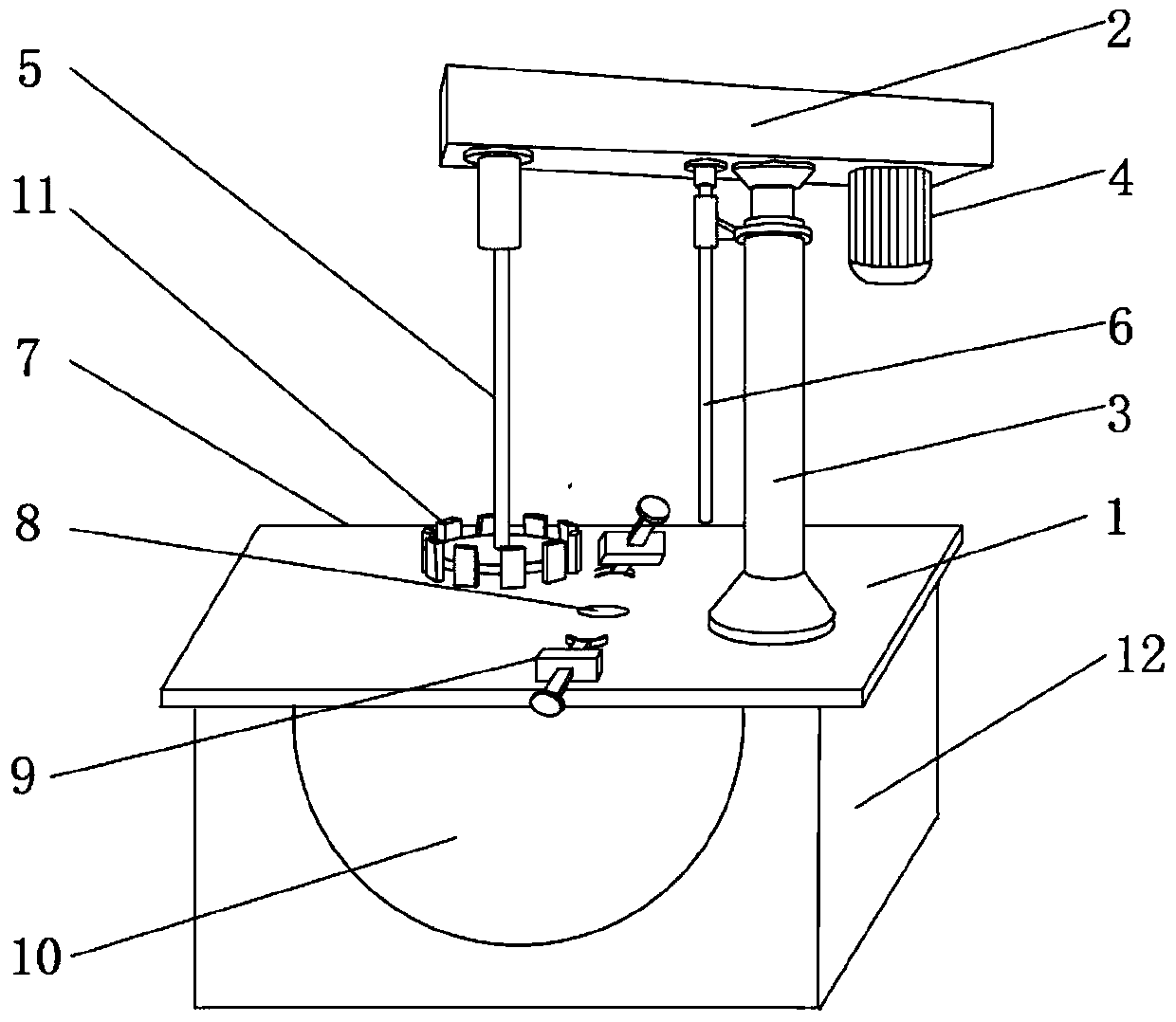

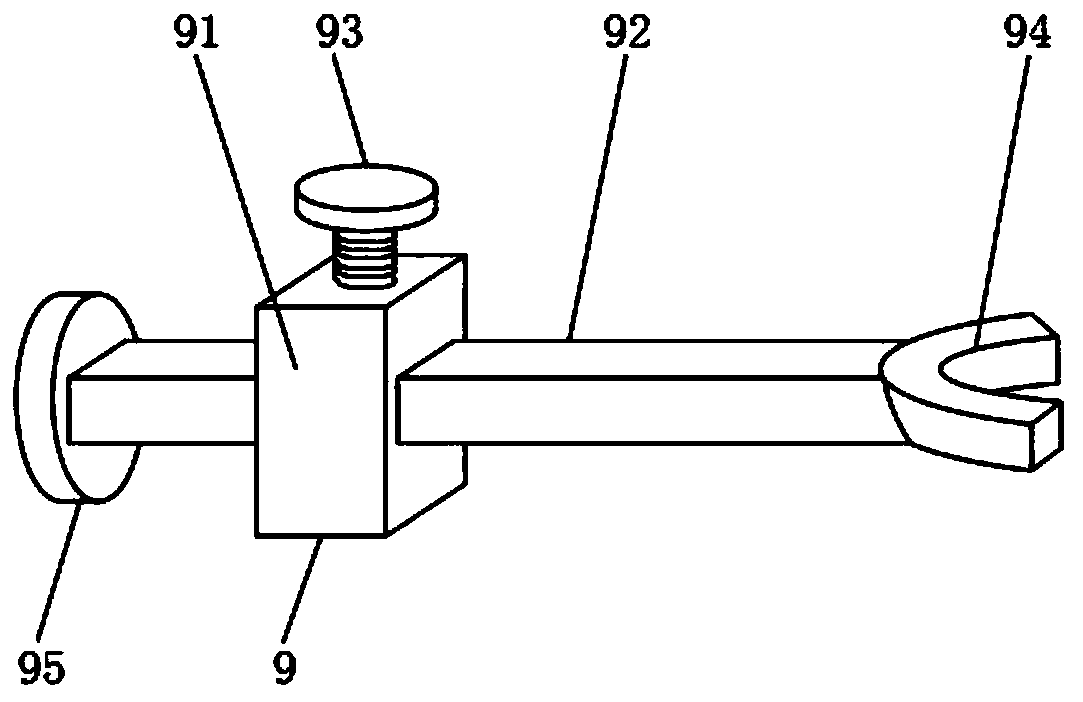

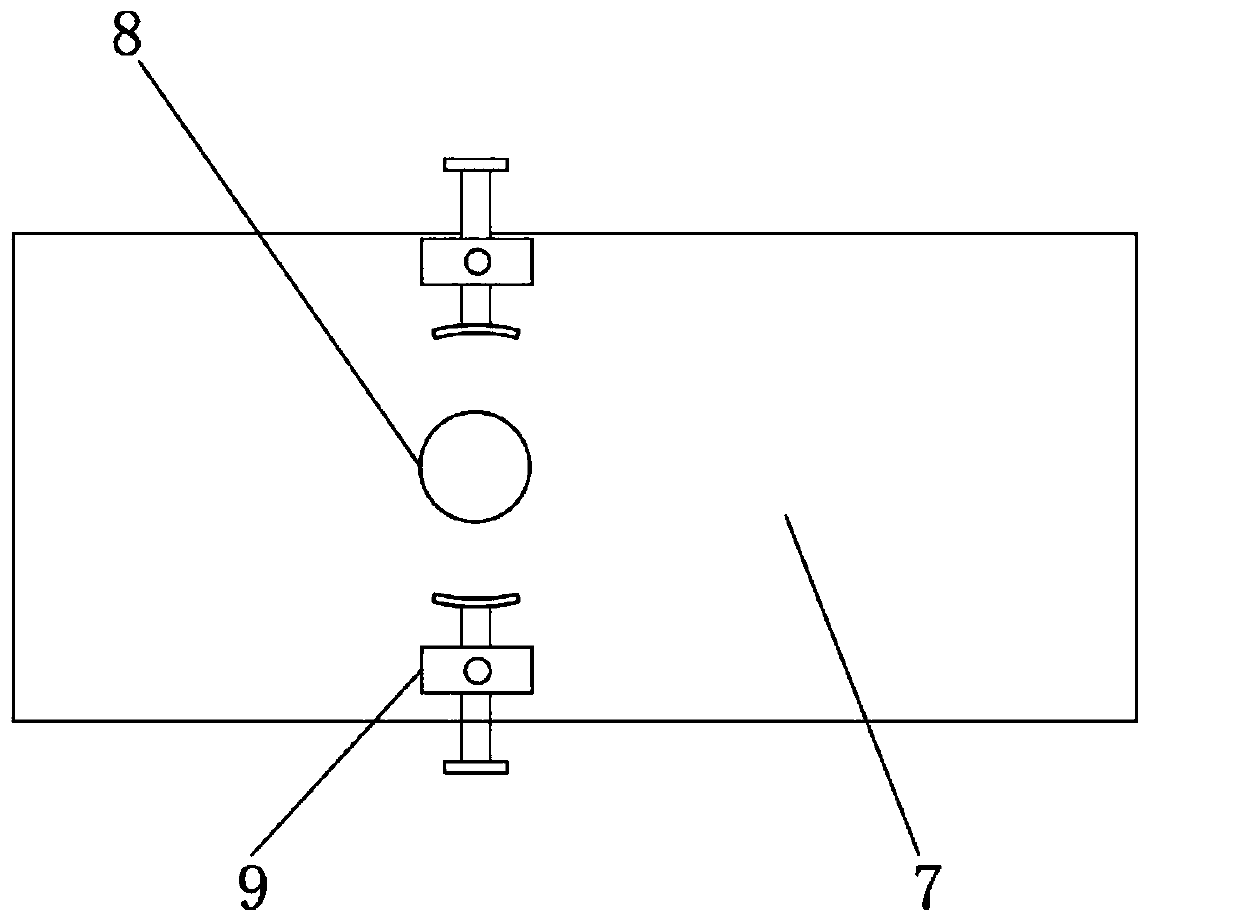

Nanometer water-based paint with high antifouling performance, and preparation method and equipment thereof

InactiveCN110938342AImprove antifouling performanceNo toxicityFireproof paintsAntifouling/underwater paintsXylyleneCopper pyrithione

The invention discloses a nanometer water-based paint with high antifouling performance. The paint is prepared from the following components in parts by weight: 100 parts of a polyurethane-acrylic emulsion, 15-20 parts of rosin, 10-15 parts of nanometer silicon dioxide, 10-15 parts of nanometer titanium dioxide, 5-10 parts of xylene, 2-5 parts of butyl acetate, 10-15 parts of copper pyrithione, 0.5-1.0 part of a surfactant and 40-50 parts of deionized water. The invention further discloses a preparation method and preparation equipment of the nanometer water-based paint with high antifouling performance. According to key points in the invention, the components, the preparation method and the equipment of the high-antifouling nanometer water-based paint are improved at the same time, so theantifouling effect of the paint is improved, and the paint is non-toxic and environmentally friendly; and meanwhile, the equipment is used for feeding while stirring, so various processes and processing methods can be integrated in one piece of equipment. The paint provided by the invention has excellent hydrophobicity and rapid, balanced and continuous hydrophobicity migration, and presents goodantifouling performance; and a coating formed by the paint is high in strength and good in adhesive force.

Owner:广东华斓汽车材料研究院

Synthesis of zinc acrylate copolymer from acid functional copolymer, zinc pyrithione, and copper compound

Disclosed is a composition containing zinc ester functional polymer and particulate copper pyrithione, wherein the particles have an average aspect ratio within a range of from about 8 to about 15, where the zinc ester functional polymer and the copper pyrithione are obtained by reacting an acid functional polymer with zinc pyrithione and a copper salt or a copper carboxylate. Also disclosed is an antifouling coating containing such a composition.

Owner:ARCH CHEM INC

Coating and preparation method thereof

InactiveCN114410140AHigh glossHigh temperature resistantFireproof paintsAnti-corrosive paintsFiberCopper pyrithione

The invention relates to a coating and a preparation method thereof, the coating comprises the following raw material component mixture A: 40-45 parts of titanium dioxide sol, 15-20 parts of isocyanate, 30-40 parts of polyethylene glycol, 10-15 parts of cosolvent, 5-8 parts of talcum powder, 7-12 parts of silicon dioxide dispersion liquid, 5-15 parts of aluminum silicate fiber, 1.5-2 parts of isobutyl acrylate, 5-10 parts of allyl phosphate, 20-30 parts of copper pyrithione, 10-20 parts of film-forming agent, 1.6-2 parts of dispersing agent and 1-5 parts of polyethyleneimine; the coating is prepared under the cooperation of preparation process steps and technical parameters, and at least has the following advantages that the coating is high in glossiness, resistant to high temperature, good in surface hardness, high in corrosion resistance, good in adhesiveness, not prone to falling off, high in contact adhesive force with the metal surface, high in paint film hardness, good in coloring effect, not prone to agglomeration, good in color fastness, good in corrosion resistance and the like. The paint is suitable for surface treatment and decoration of various metals, and has good comprehensive performance even in a high-temperature environment, so that the performance of the paint is obviously improved.

Owner:岑卫康

Preparation method of silicone modified acrylic hydrogel antifouling coating

ActiveCN105219206BImprove adhesionPrevent adhesionAntifouling/underwater paintsPaints with biocidesSelf-healingAdjuvant

A preparation method of a silicone-modified acrylic hydrogel antifouling coating, the steps of: first synthesizing a silicone-modified acrylic resin, and then preparing a hydrogel antifouling coating: the antifouling coating is composed of A and B components For two-component coatings, the mass ratio of component A and component B is 8:1, and component A is the resin base material carrier, and the ingredients are: 55-65 parts of silicone modified acrylic resin, 4-4 parts of iron oxide red 6 parts, 0.5-1.5 parts of organic bentonite, 4-6 parts of zinc oxide, 7-9 parts of copper pyrithione, 8-10 parts of Sea‑Nine211 antifouling agent, 10-12 parts of organic solvent; component B is cross-linked agent carrier, the components are 25-35 parts of aziridine cross-linking agent, 60-70 parts of n-butanol, and 4-6 parts of water; the above-mentioned parts are parts by mass. The invention introduces silicone into the acrylic resin system by chemical method, and then cooperates with appropriate additives and antifouling agents to form a low-surface organic silicon antifouling barrier layer, so that the coating has the functions of self-layering and self-repairing, not only the process Simple, good anti-fouling effect, and the amount of anti-fouling agent is small, effectively prolonging the anti-fouling effect.

Owner:舟山市知识产权促进会

Composite biocidal particles

InactiveUS8158158B2Reducing inhibiting growthAntibacterial agentsHeavy metal active ingredientsSodium PyrithioneCopper pyrithione

A biocidal composition is disclosed comprising composite particles, each of said composite particles containing a shell and a core, said core comprising a metal or a metal-containing compound wherein the metal is a moiety selected from the group consisting of zinc, copper, bismuth, silver, zirconium, and combinations thereof said shell comprising a pyrithione adduct comprising the reaction product of pyrithione with a portion of said core metal or metal compound. In one aspect, an anti-fouling composition is disclosed comprising (a) an anti-soft-fouling effective amount of copper pyrithione; and (b) an anti-hard-fouling effective amount of a copper-containing salt, or oxide or hydroxide thereof. The present invention also relates to a method of making an anti-fouling composition comprising particles of copper pyrithione and a copper-containing salt that is effective against hard-fouling and soft-fouling organisms.

Owner:ARCH CHEM INC

Antimicrobial paint composition and related methods

Owner:BEHR PROCESS

Synthesis of copper pyrithione from zinc pyrithione and copper compound

InactiveUS9540520B2Easily mixed into paintSafe handlingBiocideOrganic chemistrySodium PyrithioneCompound a

Owner:ARCH CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com