Anti-microbial antistatic PET composite material and preparation method thereof

A composite material and antistatic technology, which is applied in the field of antibacterial and antistatic PET composite materials and its preparation, can solve the problems that the antibacterial performance and antistatic performance of PET materials cannot meet the requirements of specific fields, achieve great promotion value, improve antibacterial performance, Effect of lowering surface resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

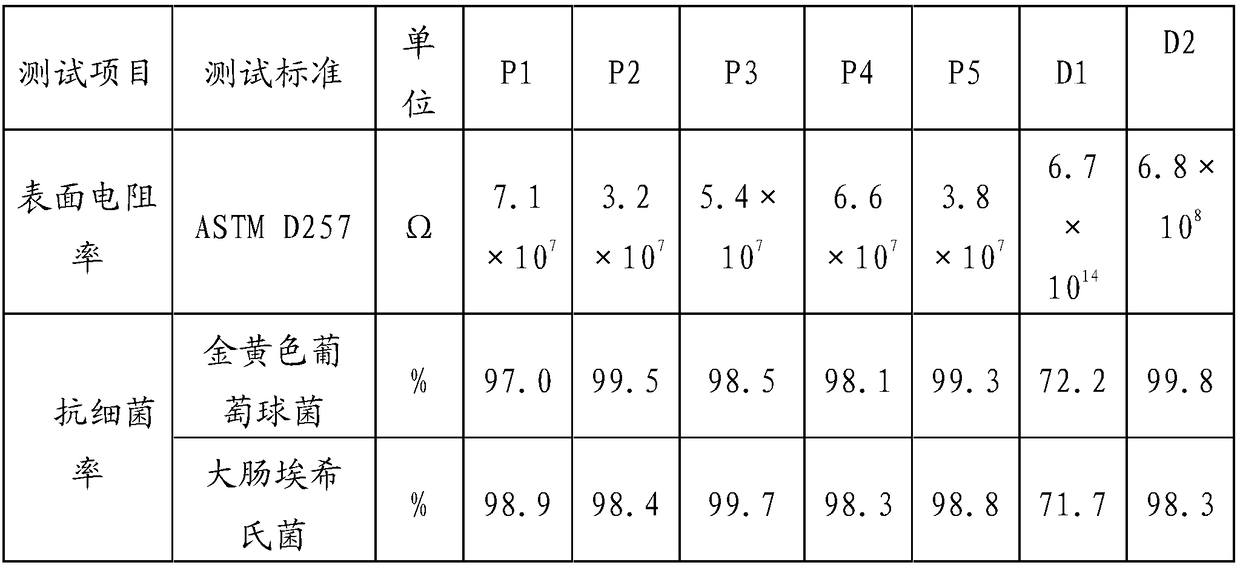

Examples

preparation example Construction

[0034] The preparation method of antibacterial agent, comprises the following steps:

[0035] (1) Take a certain amount of zeolite, copper nitrate solution and deionized water, and add them into a three-necked flask to form solution A; the mass ratio of zeolite, copper nitrate solution and deionized water is (20-28):( 60-80): (200-240).

[0036] (2) Adjust the pH value of solution A to 6-7 with nitric acid, and react in a water bath at 60-80° C. for 4-6 hours to obtain solution B;

[0037] (3) Filtrating, washing, drying and grinding solution B to obtain copper-loaded zeolite;

[0038] (4) Weigh a certain amount of sodium α-mercaptopyridine-N-oxide, N,N dimethylformamide and copper-loaded zeolite, put them into a reaction vessel, and react in a water bath at 70-90°C for 2-4 hours, Filter, wash, dry, grind, and pass through a 400-mesh sieve to obtain the antibacterial agent. The mass ratio of α-mercaptopyridine-N-oxide sodium, N,N dimethylformamide and copper-loaded zeolite ...

Embodiment 1

[0046] (1) Weigh 80 parts of PET, 2 parts of antibacterial agent, 1 part of nano-indium trioxide, 3 parts of polyvinyl alcohol, 0.1 part of Irganox168 and mix and stir evenly to obtain a mixture;

[0047] (2) Extruding and granulating the mixture obtained in step (1) to obtain PET composite material P1.

[0048] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 240°C, the temperature of the second zone is 280°C, the temperature of the third zone is 280°C, the temperature of the fourth zone is 280°C, the temperature of the fifth zone is 280°C, and the temperature of the sixth zone is 280°C. The head temperature is 280°C, and the screw speed is 200r / min.

Embodiment 2

[0050] (1) Weigh 100 parts of PET, 6 parts of antibacterial agent, 2 parts of nano-indium trioxide, 6 parts of polyvinyl alcohol, 0.1 part of Irganox168, 0.2 part of Irganox1010, 0.2 part of Irganox1330 and mix them evenly to obtain a mixture;

[0051] (2) extruding and granulating the mixture obtained in the step (1) to obtain PET composite material P2.

[0052]Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 260°C, the temperature of the second zone is 300°C, the temperature of the third zone is 300°C, the temperature of the fourth zone is 300°C, the temperature of the fifth zone is 300°C, and the temperature of the sixth zone is 300°C. The head temperature is 300°C, and the screw speed is 280r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com