Nanometer water-based paint with high antifouling performance, and preparation method and equipment thereof

A water-based coating and anti-fouling technology, applied in the direction of anti-fouling/underwater coatings, fire-resistant coatings, rosin coatings, etc., can solve the problems of inability to achieve environmental protection of materials, high-efficiency anti-fouling, insufficient anti-fouling effect, and inability to add materials. Achieve continuous hydrophobic migration, excellent hydrophobicity, and reduce the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

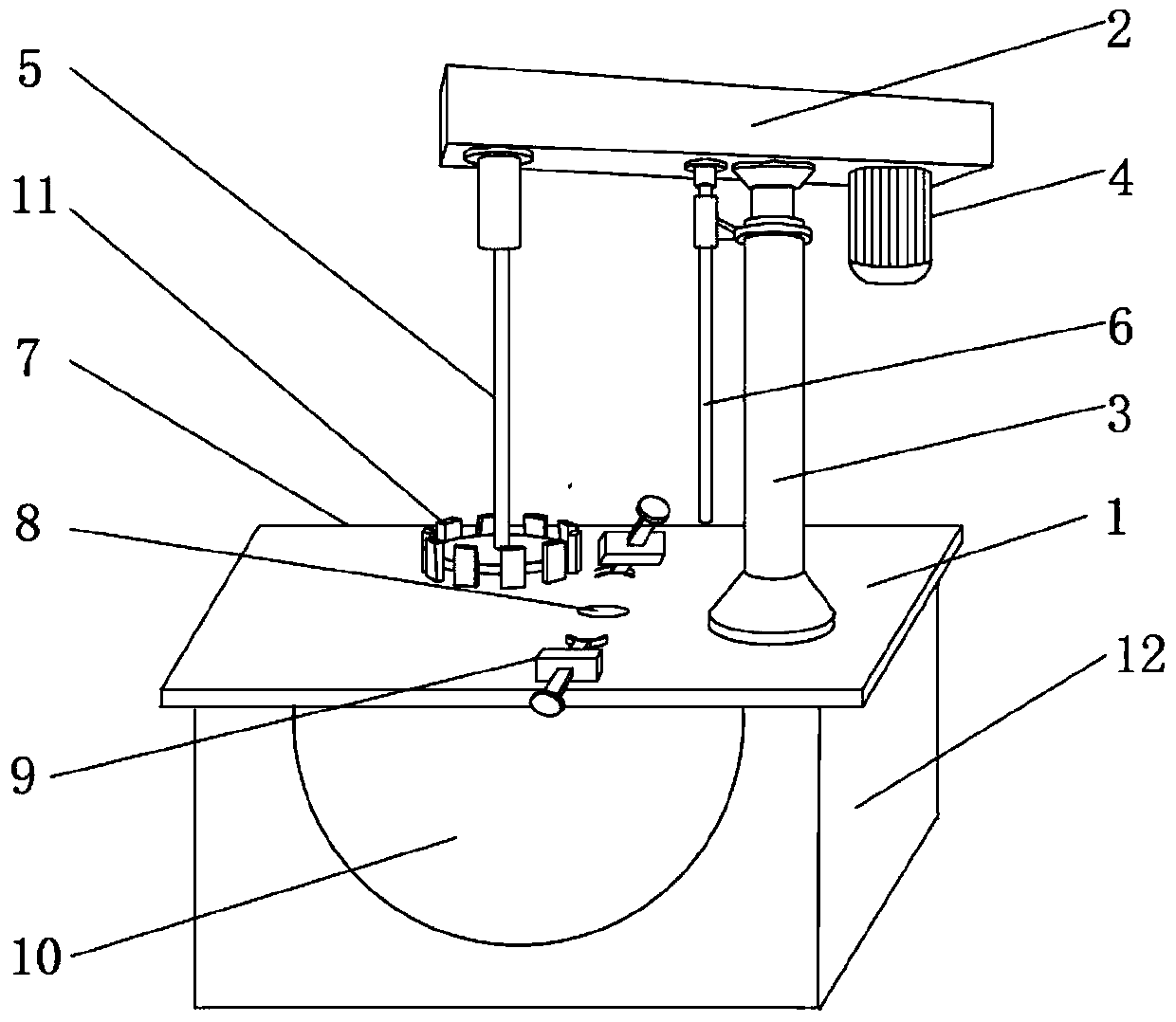

[0034] see Figure 1-3 , the high anti-fouling nano water-based paint provided by the present embodiment is made of the following parts by weight: 100 parts of polyurethane-acrylic acid emulsion, 15-20 parts of rosin, 10-15 parts of nano-silica, 10-15 parts of nano-titanium dioxide 5-10 parts of xylene, 2-5 parts of butyl acetate, 10-15 parts of copper pyrithione, 0.5-1.0 parts of surfactant, and 40-50 parts of deionized water.

[0035]Specifically, in the present embodiment, the high anti-fouling nano water-based paint is made of the following parts by weight: 100 parts of polyurethane-acrylic acid emulsion, 15 parts of rosin, 12 parts of nano-silica, 13 parts of nano-titanium dioxide, xylene 8 parts, 4 parts of butyl acetate, 12 parts of copper pyrithione, 0.8 parts of surfactant, 45 parts of deionized water. The surfactant is sodium hexametaphosphate.

[0036] The polyurethane-acrylic acid emulsion is prepared by the following steps: in a nitrogen atmosphere, mix p-phenyl...

Embodiment 2

[0051] The high antifouling nano water-based paint, preparation method and equipment provided by the embodiments of the present invention are basically the same as in Example 1, except that:

[0052] In the present embodiment, the high anti-fouling nano water-based paint is made of the following parts by weight: 100 parts of polyurethane-acrylic acid emulsion, 20 parts of rosin, 10 parts of nano silicon dioxide, 10 parts of nano titanium dioxide, 5 parts of xylene, 2 parts of butyl acetate, 10 parts of copper pyrithione, 0.5 parts of surfactant, 40 parts of deionized water.

Embodiment 3

[0054] The high antifouling nano water-based paint, preparation method and equipment provided by the embodiments of the present invention are basically the same as in Example 1, except that:

[0055] In the present embodiment, the high anti-fouling nano water-based paint is made of the following parts by weight: 100 parts of polyurethane-acrylic acid emulsion, 18 parts of rosin, 15 parts of nano silicon dioxide, 15 parts of nano titanium dioxide, 10 parts of xylene, 5 parts of butyl acetate, 15 parts of copper pyrithione, 1 part of surfactant, 50 parts of deionized water.

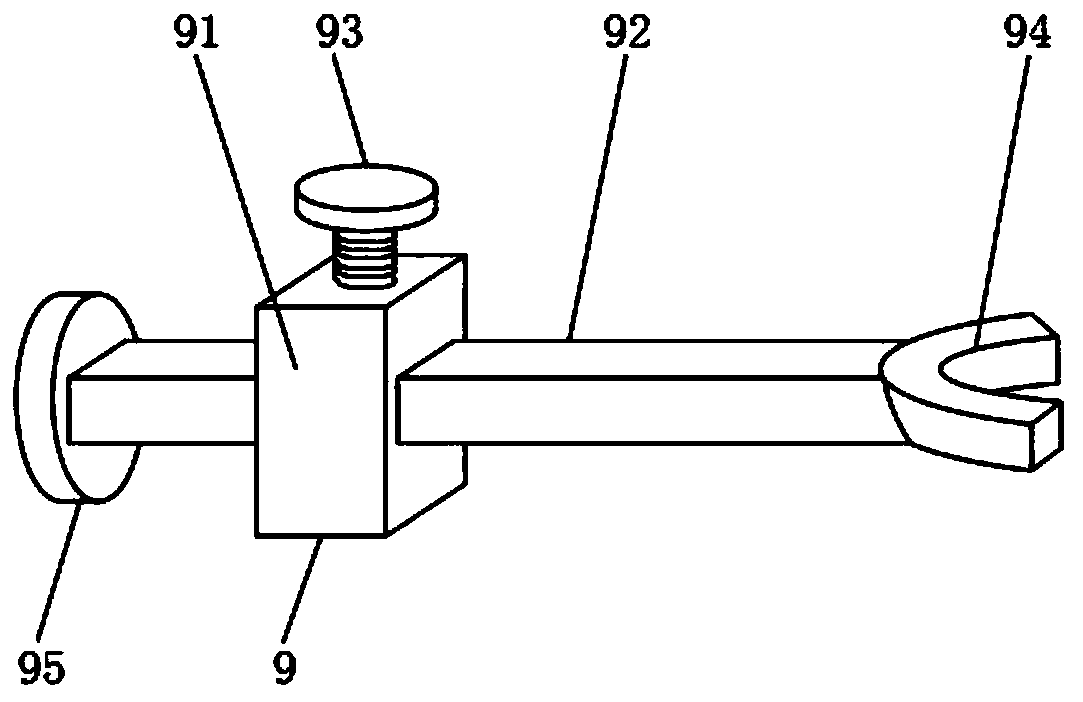

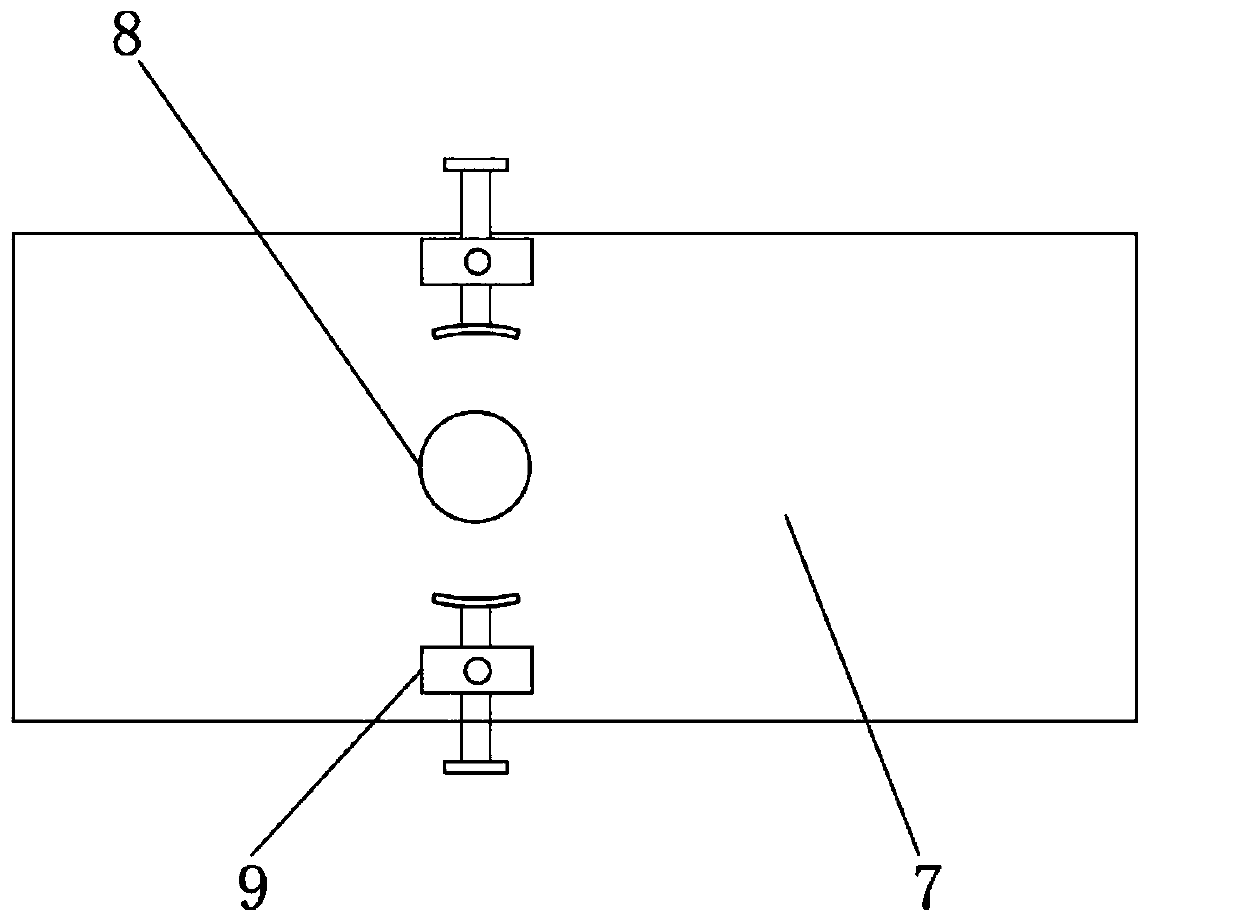

[0056] The components used in the present invention, and the use process of stirring plate 11, suspension arm 2, support arm 3, stirring motor 4, stirring rod 5 and stop rod 6 and the above-mentioned parts all adopt the background information provided by the present invention. , and with the elaboration of the description of the present invention, those skilled in the art can obtain its use process and obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com