Mildew-proof antibacterial silicone rubber fabric and production process thereof

An anti-mildew and antibacterial, silicone rubber technology, applied in the field of textile fabrics, can solve the problems of no more than 50% anti-mildew and anti-bacterial effect, weak anti-mildew and anti-bacterial effect, etc. The effect of strength and tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The silicone rubber fabric of Example 1 obtained by the following operation steps:

[0038] According to the amount of Table 1, silver nano-titanium dioxide, bamboo charcoal powder, pyridone copper, sodium hexagonophosphate, butyl hydroxybenzate and trimethylolpropane trimethyl methacrylate (vulcanizing agent) are added to A In the base silicone rubber, 40 min is mixed under 50 ° C for 40 min to obtain a mixture A;

[0039] The mixture A was applied to the release paper, bonded to the flame retardation, for 10 minutes at a temperature of 140 ° C, and peeled off the paper to obtain silicone rubber fabric.

Embodiment 2-5

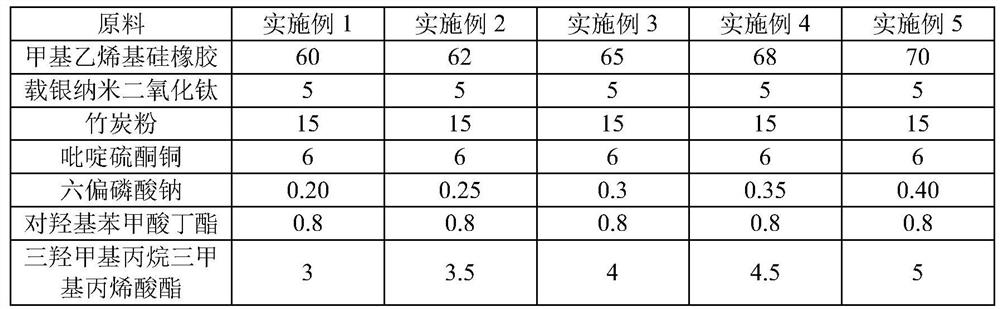

[0041]The silicone rubber fabric of Example 2-5 was identical to the preparation method of Example 1 and the type of raw material, and the difference is that the amount of raw materials is different, as shown in Table 1, specifically shown in Table 1.

[0042] Table 1 Example 1-5 Silicone Rubber fabric of each raw material duct (unit: kg)

[0043]

Embodiment 6-9

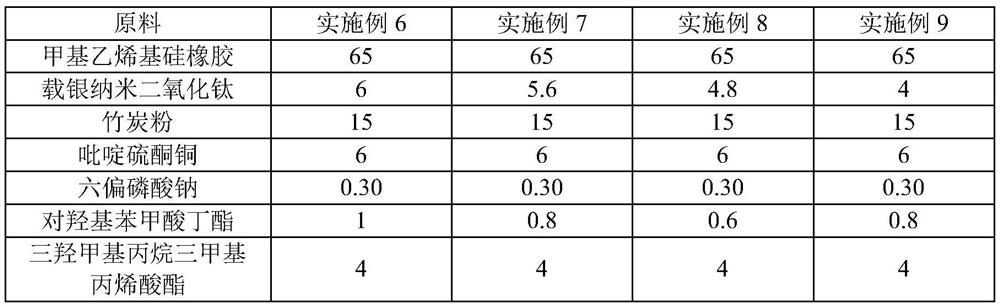

[0045] The silicone rubber fabric of Example 6-9 is exactly the same as the preparation method of Example 3 and the type of raw material, and the difference is that the amount of raw materials is different, as shown in Table 2, specifically shown in Table 2.

[0046] Table 2 Example 6-9 Each raw material dosage of silicone rubber fabric (unit: kg)

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com