High-speed railway construction installation cable

A cable and high-speed rail technology, applied in the field of high-speed rail construction and installation of cables, can solve problems such as poor cable use, achieve soft texture, improve performance, and superior flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

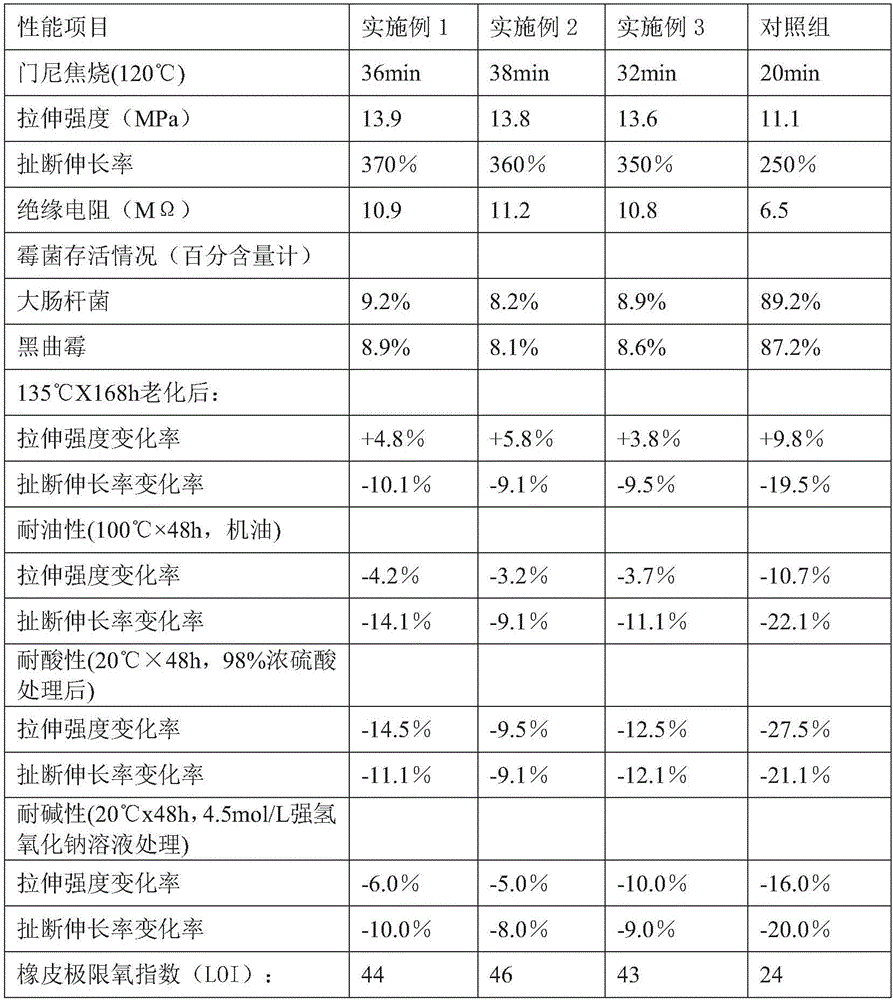

Embodiment 1

[0017] The high-speed rail construction and installation cable in this embodiment includes multiple copper alloy conductors and protective sleeves. The copper alloy conductors are placed parallel to each other. The outer layer of each copper alloy conductor is covered with a protective sleeve. The protective sleeve is composed of the following parts by mass: Component composition: 24 parts of epichlorohydrin rubber, 22 parts of rosin resin, 22 parts of isoprene rubber, 20 parts of dipropylene glycol methyl ether, 22 parts of dimethyl sulfoxide, 22 parts of diisobutyl ketone, 20 parts of modified hydrogenated castor oil , 22 parts of silicone resin polyether emulsion, 22 parts of ethyl paraben sodium salt, 20 parts of calcium borate, 20 parts of propargyl chloride, 20 parts of hexadecyl bromide, 22 parts of wood powder, 20 parts of wood fiber, molybdic acid 18 parts of sodium, 22 parts of nano-barium sulfate, 20 parts of nano-carbon powder, 18 parts of nano-alumina powder, 20 pa...

Embodiment 2

[0024] The high-speed rail construction and installation cable in this embodiment includes multiple copper alloy conductors and protective sleeves. The copper alloy conductors are placed parallel to each other. The outer layer of each copper alloy conductor is covered with a protective sleeve. The protective sleeve is composed of the following parts by mass: Component composition: 26 parts of epichlorohydrin rubber, 24 parts of rosin resin, 24 parts of isoprene rubber, 22 parts of dipropylene glycol methyl ether, 24 parts of dimethyl sulfoxide, 24 parts of diisobutyl ketone, 22 parts of modified hydrogenated castor oil , Silicone resin polyether emulsion 24 parts, ethylparaben sodium salt 24 parts, calcium borate 22 parts, propargyl chloride 22 parts, hexadecyl bromide 22 parts, wood powder 24 parts, wood fiber 22 parts, molybdic acid 20 parts of sodium, 24 parts of nano-barium sulfate, 22 parts of nano-carbon powder, 20 parts of nano-alumina powder, 22 parts of nano-titanium o...

Embodiment 3

[0031] The high-speed rail construction and installation cable in this embodiment includes multiple copper alloy conductors and protective sleeves. The copper alloy conductors are placed parallel to each other. The outer layer of each copper alloy conductor is covered with a protective sleeve. The protective sleeve is composed of the following parts by mass: Component composition: 28 parts of epichlorohydrin rubber, 26 parts of rosin resin, 26 parts of isoprene rubber, 24 parts of dipropylene glycol methyl ether, 26 parts of dimethyl sulfoxide, 26 parts of diisobutyl ketone, 24 parts of modified hydrogenated castor oil , Silicone resin polyether emulsion 26 parts, ethylparaben sodium salt 26 parts, calcium borate 24 parts, propargyl chloride 24 parts, hexadecyl bromide 24 parts, wood powder 26 parts, wood fiber 24 parts, molybdic acid 22 parts of sodium, 26 parts of nano-barium sulfate, 24 parts of nano-carbon powder, 22 parts of nano-alumina powder, 24 parts of nano-titanium o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com