Environment-friendly coating for civil construction road and bridge construction bridge connecting railing surface

A technology for civil construction, road and bridge, which is applied in the field of environmental protection coating on the surface of bridge connecting railings in civil construction, road and bridge construction, which can solve the problems of poor application effect of coating materials, achieve superior flame retardancy, improve product performance, anti-mildew and antibacterial properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

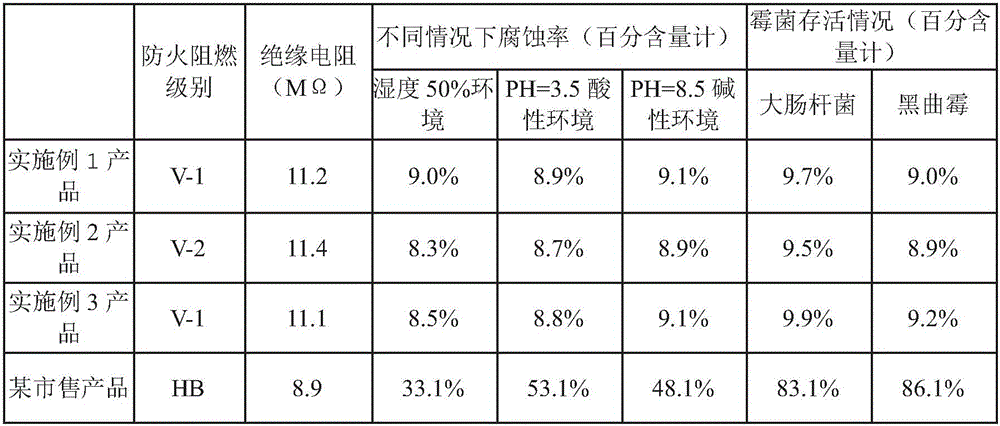

Examples

Embodiment 1

[0016] The environmental protection coating on the surface of the bridge connecting railing for civil engineering construction, road and bridge construction in this embodiment is composed of the following components in parts by mass: 30 parts of methyl vinyl silicone rubber, 28 parts of polyurethane, and 28 parts of polystyrene resin , 26 parts of soybean oil, 28 parts of wintergreen oil, 28 parts of dimethyl sulfoxide, 26 parts of diisobutyl ketone, 28 parts of caprylic acid ester, 28 parts of zinc pyrithione, 10,10'-oxobisphenox 26 parts of arsenic, 26 parts of potassium sorbate, 26 parts of imperata, 28 parts of aluminum fluoride powder, 26 parts of cobalt chloride hexahydrate, 24 parts of sucrose, 28 parts of barium chromate powder, 26 parts of ferrous sulfate, 24 parts of polyester yarn 26 parts of zinc sulfide, 24 parts of attapulgite powder, 24 parts of zinc hydroxystannate, 26 parts of decabromodiphenyl ether, 26 parts of sodium antimonate, 26 parts of zinc stannate, γ-...

Embodiment 2

[0022] The environmental protection coating on the surface of the bridge connecting railings for civil engineering construction, road and bridge construction in this embodiment is composed of the following components in parts by mass: 32 parts of methyl vinyl silicone rubber, 30 parts of polyurethane, and 30 parts of polystyrene resin , 28 parts of soybean oil, 30 parts of wintergreen oil, 30 parts of dimethyl sulfoxide, 28 parts of diisobutyl ketone, 30 parts of caprylic acid ester, 30 parts of zinc pyrithione, 10,10'-oxobisphenox 28 parts of arsenic, 28 parts of potassium sorbate, 28 parts of imperate, 30 parts of aluminum fluoride powder, 28 parts of cobalt chloride hexahydrate, 26 parts of sucrose, 30 parts of barium chromate powder, 28 parts of ferrous sulfate, 26 parts of polyester yarn 28 parts, 28 parts of zinc sulfide, 26 parts of attapulgite powder, 26 parts of zinc hydroxystannate, 28 parts of decabromodiphenyl ether, 28 parts of sodium antimonate, 28 parts of zinc s...

Embodiment 3

[0028] The environmental protection coating on the surface of the bridge connecting railings for civil engineering construction, road and bridge construction in this embodiment is composed of the following components in parts by mass: 34 parts of methyl vinyl silicone rubber, 32 parts of polyurethane, and 32 parts of polystyrene resin , 30 parts of soybean oil, 32 parts of wintergreen oil, 32 parts of dimethyl sulfoxide, 30 parts of diisobutyl ketone, 32 parts of caprylic acid ester, 32 parts of zinc pyrithione, 10,10'-oxobisphenox 30 parts of arsenic, 30 parts of potassium sorbate, 30 parts of imperata, 32 parts of aluminum fluoride powder, 30 parts of cobalt chloride hexahydrate, 28 parts of sucrose, 32 parts of barium chromate powder, 30 parts of ferrous sulfate, 28 parts of polyester yarn , 30 parts of zinc sulfide, 28 parts of attapulgite powder, 28 parts of zinc hydroxystannate, 30 parts of decabromodiphenyl ether, 30 parts of sodium antimonate, 30 parts of zinc stannate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com