Multifunctional power maintenance glove material

A multi-functional, electric technology, applied in the field of electric power, can solve problems such as poor effect and short service life of gloves, achieve superior flame retardancy and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

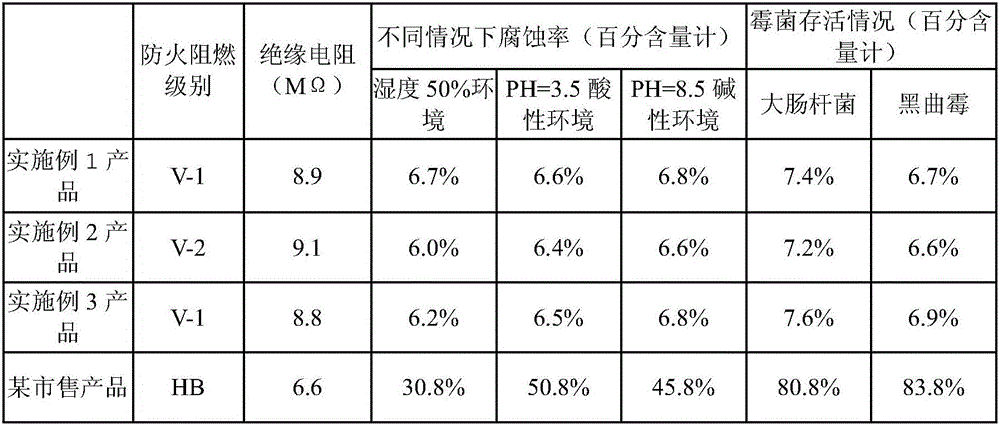

Examples

Embodiment 1

[0016] The multifunctional power maintenance glove material in this embodiment is composed of the following components by mass: 30 parts of o-cresol novolac epoxy resin, 28 parts of diisocyanate, 28 parts of fluororubber, 26 parts of grape seed oil, and 28 parts of Turkish oil 28 parts, triglyceride oleate, 26 parts palm oil, 28 parts dimethyl sulfoxide, 28 parts biguanide trioctylbenzene sulfonate, 26 parts polyhexamethylene guanidine, stearamidopropyl pyrrolidone 26 parts of methyl dimethyl ammonium chloride, 26 parts of nano silver, 28 parts of lithopone, 26 parts of lithium chromate powder, 24 parts of magnesium sulfate, 28 parts of potassium aluminum sulfate dodecahydrate, 26 parts of aluminum phosphate powder, 24 parts of sodium metasilicate in water, 26 parts of wax powder, 24 parts of ammonium phosphate, 24 parts of polyacrylonitrile fiber, 26 parts of dibasic lead stearate, 26 parts of tri(butoxyethyl) phosphate, six 26 parts of bromobenzene, 26 parts of pentaerythrit...

Embodiment 2

[0022] The multifunctional power maintenance glove material in this embodiment is composed of the following components in parts by mass: 32 parts of o-cresol novolac epoxy resin, 30 parts of diisocyanate, 30 parts of fluororubber, 28 parts of grape seed oil, and 30 parts of Turkish oil 30 parts of triglyceride oleate, 28 parts of palm oil, 30 parts of dimethyl sulfoxide, 30 parts of biguanide trioctylbenzene sulfonate, 28 parts of polyhexamethylene guanidine, stearamidopropyl pyrrolidone 28 parts of methyl dimethyl ammonium chloride, 28 parts of nano silver, 30 parts of lithopone, 28 parts of lithium chromate powder, 26 parts of magnesium sulfate, 30 parts of potassium aluminum sulfate dodecahydrate, 28 parts of aluminum phosphate powder, 26 parts of sodium metasilicate in water, 28 parts of wax powder, 26 parts of ammonium phosphate, 26 parts of polyacrylonitrile fiber, 28 parts of dibasic lead stearate, 28 parts of tri(butoxyethyl) phosphate, six 28 parts of bromobenzene, 28...

Embodiment 3

[0028] The multifunctional power maintenance glove material in this embodiment is composed of the following components in parts by mass: 34 parts of o-cresol novolac epoxy resin, 32 parts of diisocyanate, 32 parts of fluororubber, 30 parts of grape seed oil, and 32 parts of Turkish oil 32 parts, triglyceride oleate, 30 parts palm oil, 32 parts dimethyl sulfoxide, 32 parts biguanide trioctylbenzene sulfonate, 30 parts polyhexamethylene guanidine, stearamidopropyl pyrrolidone 30 parts of methyl dimethyl ammonium chloride, 30 parts of nano silver, 32 parts of lithopone, 30 parts of lithium chromate powder, 28 parts of magnesium sulfate, 32 parts of potassium aluminum sulfate dodecahydrate, 30 parts of aluminum phosphate powder, 28 parts of sodium metasilicate in water, 30 parts of wax powder, 28 parts of ammonium phosphate, 28 parts of polyacrylonitrile fiber, 30 parts of dibasic lead stearate, 30 parts of tri(butoxyethyl) phosphate, six 30 parts of bromobenzene, 30 parts of pent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com