Surface micro-structure self-polishing antifouling coating and preparation method thereof

An anti-fouling coating and self-polishing technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc. , it is difficult to play an anti-fouling effect, etc., to achieve the effect of easy control of process conditions, easy industrial production, and long-term anti-fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

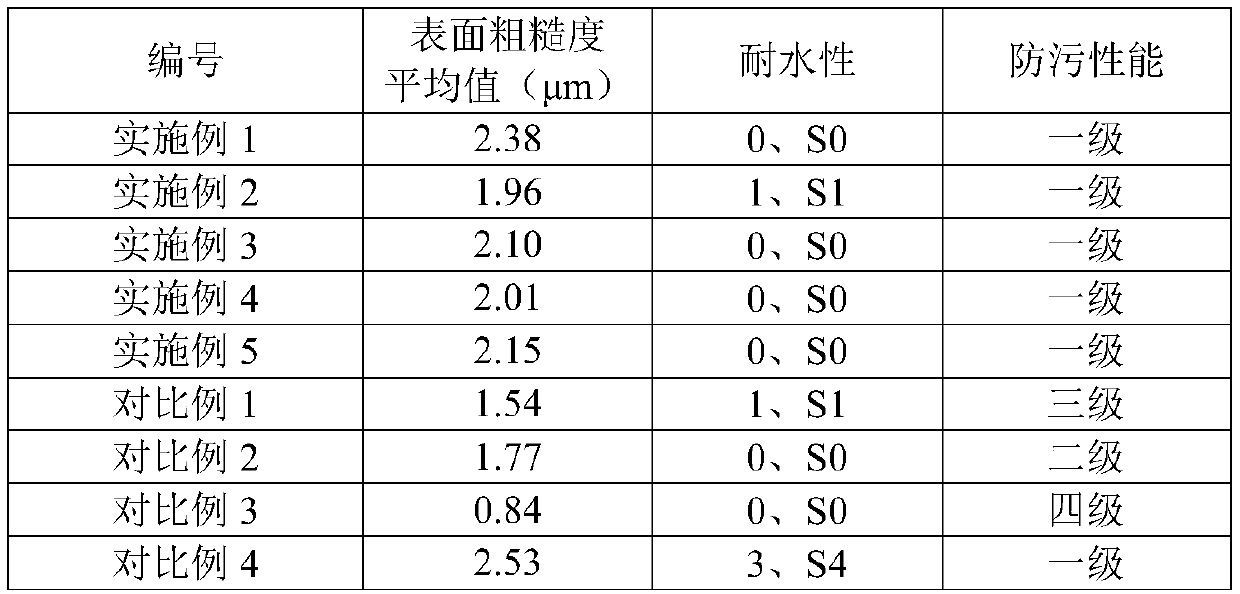

Examples

Embodiment 1

[0039] (1) Preparation of resin: first add 180g of xylene solvent in a 500mL four-neck flask equipped with a stirrer, reflux condensing device, semi-automatic sampling device, and ventilation tube, control the stirring speed to be 150 rpm, and feed nitrogen to remove After oxygen for 30 minutes, the solvent was heated to 85°C and a constant nitrogen pressure was maintained; then 117.2g tert-butyl methacrylate, 40g triisopropyl methacrylate silicone grease, 2.8g acrylic acid monomer and 1.28g azobis The mixed solution of isobutyronitrile is added dropwise to the solvent at a uniform speed through a semi-automatic dropping device, and the dropping time is controlled to be 3 hours; after the dropping is completed, continue to keep warm for 4 hours;

[0040] (2) Preparation of microspheres: Add 1.8g of acrylamide, 0.016g of N,N'-methylenebisacrylamide , 0.9g methacrylic acid, 3.6g self-made dispersant, 0.06g azobisisobutyronitrile, 110g n-butanol mixed solution, feed nitrogen for ...

Embodiment 2

[0043] (1) Preparation of resin: first add the mixed solvent mass ratio (7:3) of 180 dimethylbenzene and n-butanol in the 500mL four-neck flask equipped with stirrer, reflux condensing device, semi-automatic sampling device, ventilation tube, Control the stirring speed to 160 rpm, pass through nitrogen to remove oxygen for 30 minutes, then heat the solvent to 85°C and maintain a constant nitrogen pressure; then mix 123g methyl methacrylate, 54g tributyl silicon methacrylate, 3g acrylic monomer 1. The mixed solution of 28g of azobisisobutyronitrile was added dropwise to the solvent at a constant speed through a semi-automatic dropping device, and the dropping time was controlled to be 4 hours; after the dropping was completed, the reaction was continued for 4 hours;

[0044] (2) Preparation of microspheres: Add 2.2 g of acrylamide and 0.016 g of N,N'-methylenebisacrylamide into a 500 mL four-neck flask equipped with a stirrer, reflux condensing device, semi-automatic sampling de...

Embodiment 3

[0047] (1) Preparation of resin: first add the mixed solvent (mass ratio 9:1) of 180g xylene and n-butanol in the four-necked flask that agitator, reflux condensing device, semi-automatic sampling device, ventilation tube are housed, control The stirring speed was 200 rpm, the solvent was heated to 85° C. and a constant nitrogen pressure was maintained after 30 minutes of deoxygenation by passing nitrogen gas. Then, the mixed solution of 128.6g tert-butyl methacrylate, 28.8g triisopropyl acrylate silicone grease, 2.6g acrylic acid monomer and 1.28g azobisisobutyronitrile was dropped into the solvent at a constant speed by a semi-automatic dropping device , the dropping time is controlled to be 3.5 hours; after the dropping is completed, continue the heat preservation reaction for 3.5 hours;

[0048] (2) Preparation of microspheres: Add 2g of acrylamide, 0.016g of N,N'-methylenebisacrylamide, A mixed solution of 1g methacrylic acid, 5g self-made dispersant, 0.06g azobisisobuty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com