Preparation method of organosilicon-modified polyurethane hydrogel antifouling paint

An antifouling coating and silicone technology, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., can solve hydrogel surface damage, poor substrate adhesion, change material surface properties, etc. problems, to achieve the effects of reducing production costs, enhancing water resistance, and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

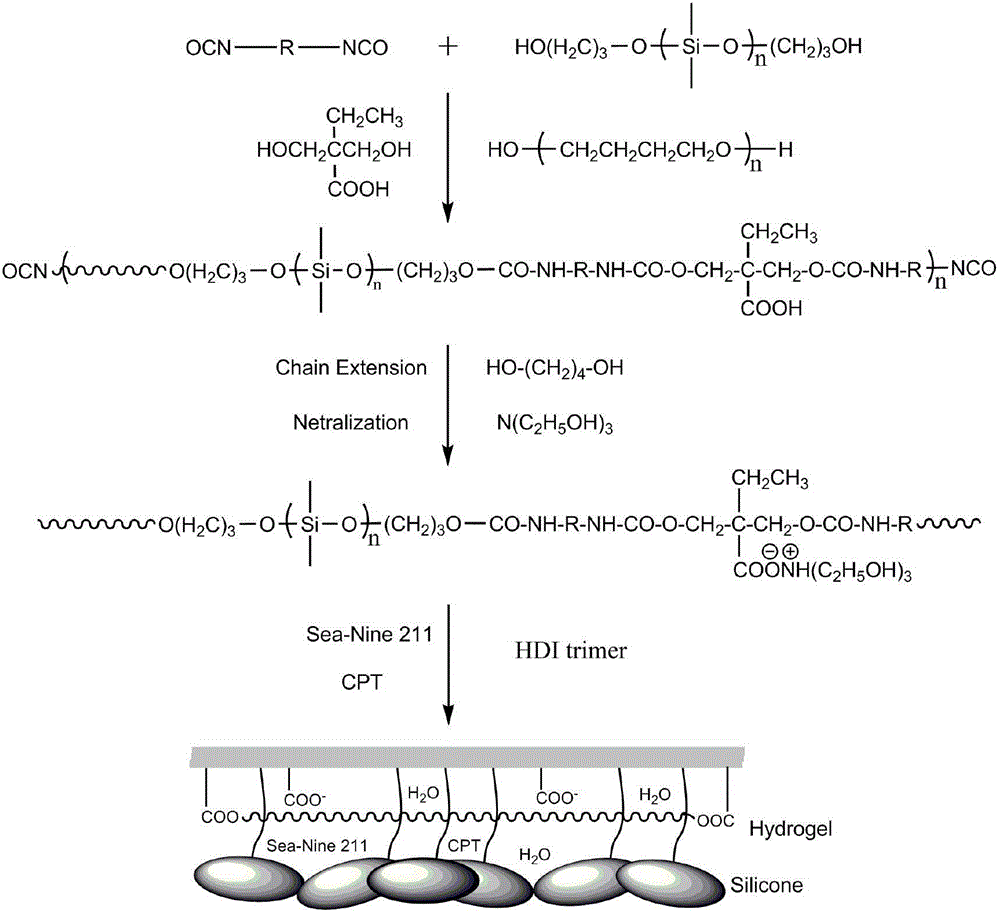

[0020] (1) Synthesis of silicone modified polyurethane resin:

[0021] Under argon protection, 200g of dry xylene was added to a 1L four-necked flask. Add 34.0g of hexamethylene diisocyanate, 4 drops of di-n-butyltin dilaurate, 100g of polytetrahydrofuran ether glycol (average molecular weight: 1000), 20g of polysiloxane diol (average molecular weight of 990) and DMBA2.00g, and raise the temperature To 80°C, after 4 hours of reaction, 3.20g of butanediol was added for chain extension. After 2 hours of reaction, 2.0 g of triethanolamine was added for neutralization for 0.5 hours. The temperature was reduced to 45°C, and 20.0 g of hexamethylene diisocyanate trimer was added to continue the reaction for 2 hours to complete the reaction. Specific synthetic route such as figure 1 Shown.

[0022] (2) Preparation of two-component hydrogel antifouling coating: The coating contains two components A and B, and the mass ratio of the A and B components is 12:1.

[0023] Among them, componen...

Embodiment 2

[0027] (1) Synthesis of silicone modified polyurethane resin:

[0028] Under argon protection, 200g of dry xylene was added to a 1L four-necked flask. Add 35.0g of toluene diisocyanate, 4 drops of di-n-butyltin dilaurate, 140g of polyethylene glycol 2000, 20g of polysiloxane diol (average molecular weight 990) and DMBA 2.00g, increase the temperature to 80°C, add butyl tin after 4 hours of reaction 3.20g diol chain extension. After 2 hours of reaction, 2.0 g of triethanolamine was added for neutralization for 0.5 hours. The temperature was lowered to 45°C, and 20.0 g of hexamethylene diisocyanate trimer was added to continue the reaction for 2 hours to complete the reaction. The specific synthesis route is the same as in Example 1.

[0029] (2) Preparation of two-component hydrogel antifouling coating: the coating contains two components A and B, and the mass ratio of the A and B components is 12:1.

[0030] Among them, component A is a resin base material carrier. The specific c...

Embodiment 3

[0034] (1) Synthesis of silicone modified polyurethane resin:

[0035] Under argon protection, 200g of dry xylene was added to a 1L four-necked flask. Add 45.0g isophorone diisocyanate, 4 drops of di-n-butyltin dilaurate, 140g polyethylene glycol 2000, 20g polysiloxane diol (average molecular weight 990) and DMBA 2.00g, heat up to 80℃, react for 4h Then 3.20 g of butanediol was added for chain extension. After 2 hours of reaction, 2.0 g of triethanolamine was added for neutralization for 0.5 hours. The temperature was lowered to 45°C, and 20.0 g of hexamethylene diisocyanate trimer was added to continue the reaction for 2 hours to complete the reaction. The specific synthesis route is the same as in Example 1.

[0036] (2) Preparation of two-component hydrogel antifouling coating: The coating contains two components A and B, and the mass ratio of the A and B components is 12:1.

[0037] Among them, component A is a resin base material carrier. The specific components are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com