Anti-microcrack coating and preparation method thereof

A micro-crack and coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient mechanical strength of the repair structure, and achieve the effect of inhibiting the generation of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0038] An anti-microcrack prepolymer, comprising the following preparation steps:

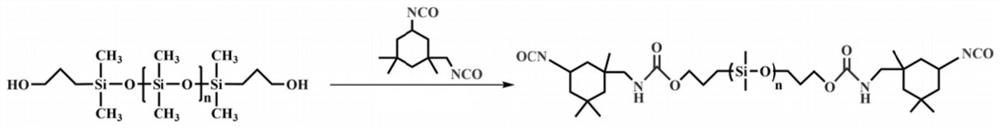

[0039] (1) 30g of hydroxyl terminated polydimethylsiloxane (viscosity 3000cSt) was placed in a dry flask, and heated under vacuum at 80°C for 2 hours to remove moisture and gas, and then 5g of isophorone diisocyanate and 0.1 g of stannous octoate was added to the flask, and stirred for 1 h under nitrogen protection to obtain mixture A. The reaction formula is as follows figure 1 shown;

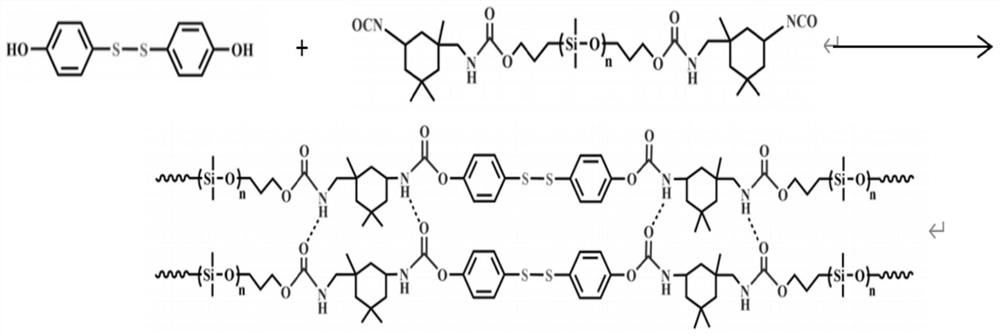

[0040] (2) under the temperature condition of 65 ℃, 5 g of bis(4-hydroxyphenyl) disulfide was dissolved in 50 g of tetrahydrofuran, and then added to the flask containing mixture A, and reacted under nitrogen protection for 30 minutes to obtain anti- Microcracked prepolymer, the reaction formula is figure 2 shown.

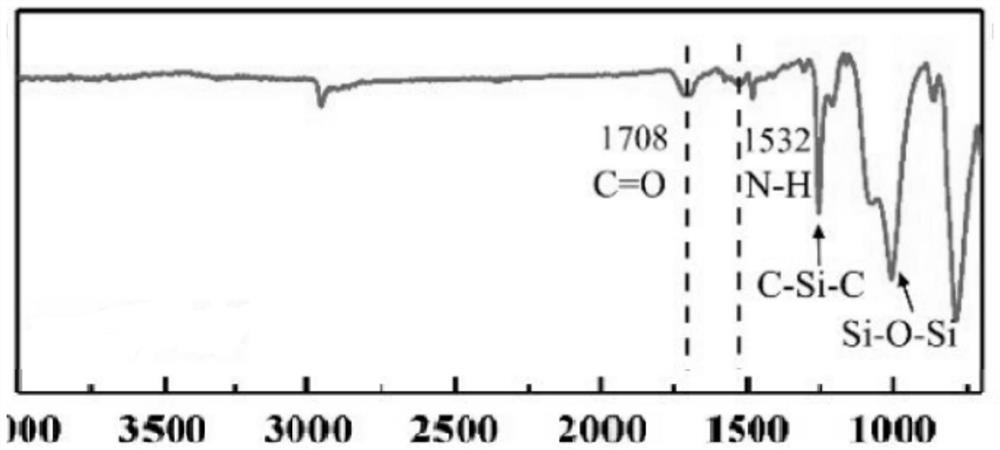

[0041] like image 3 The mid-infrared spectrum results show that the peak at 1708cm-1 is the stretching vibration of amide C=O, and the peak at 1532cm-1 belongs to the amide II band, and these ...

preparation example 2

[0044] An anti-microcrack prepolymer, comprising the following preparation steps:

[0045] (1) 50g of hydroxyl terminated polydimethylsiloxane (viscosity 2500cSt) was placed in a dry flask, and heated under vacuum at 65°C for 2 hours to remove moisture and gas, and then 8g of toluene-2,5-dimethicone was added. Isocyanate and 0.5g bis(dodecylsulfide)dibutyltin were added to the flask, and stirred for 2h under nitrogen protection to obtain mixture A;

[0046] (2) under the temperature condition of 80 ℃, dissolve 10 g of 3,3'-dihydroxydiphenyl disulfide in 50 g of tetrahydrofuran, then add it to the flask containing mixture A, and react under nitrogen protection for 40 minutes to obtain Microcrack resistant prepolymer.

preparation example 3

[0048] An anti-microcrack prepolymer, comprising the following preparation steps:

[0049] (1) 40g of hydroxyl terminated polydimethylsiloxane (viscosity 2000cSt) was placed in a dry flask, and heated under vacuum at 70°C for 1 hour to remove moisture and gas, and then 6g of hexamethylene diisocyanate and 0.3 g of dibutyltin diacetate was added to the flask, and stirred for 1 h under nitrogen protection to obtain mixture A;

[0050] (2) Under the temperature condition of 70°C, 8g of 3,3'-dihydroxydiphenyl disulfide was dissolved in 30g of tetrahydrofuran, and then added to the flask containing mixture A, and reacted under nitrogen protection for 60 minutes to obtain Microcrack resistant prepolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com