Nano-sized microcapsules, polymer-based self-healing composite material and preparation method

A technology of composite materials and microcapsules, which is applied in the field of preparation of nanoscale microcapsules for polymer-based self-healing composite materials, which can solve the problems of large capsule size, poor capsule shape and wall thickness control, and affecting self-healing efficiency, etc. problems, to achieve the effects of good coating, improved shape and size control, and high-efficiency preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

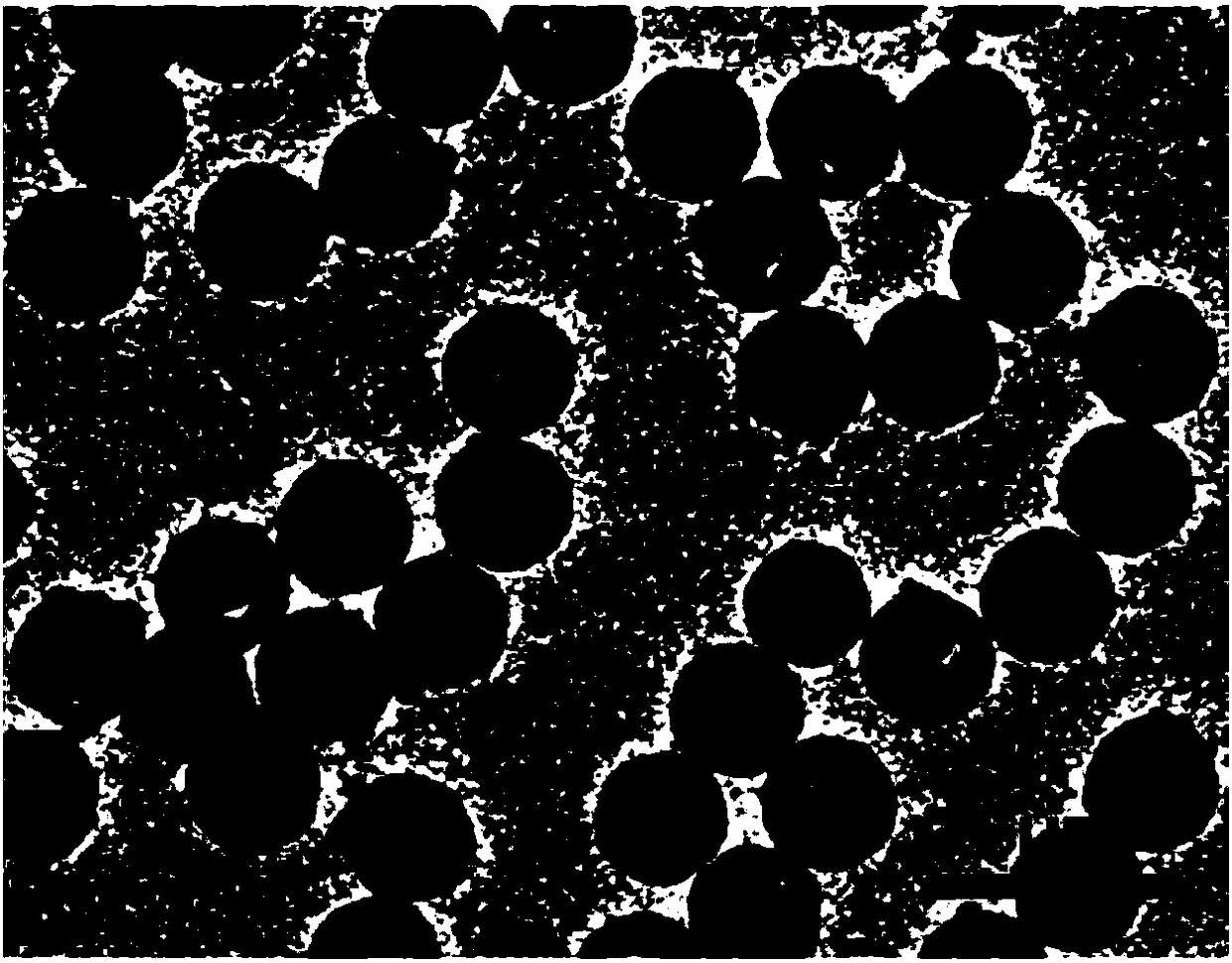

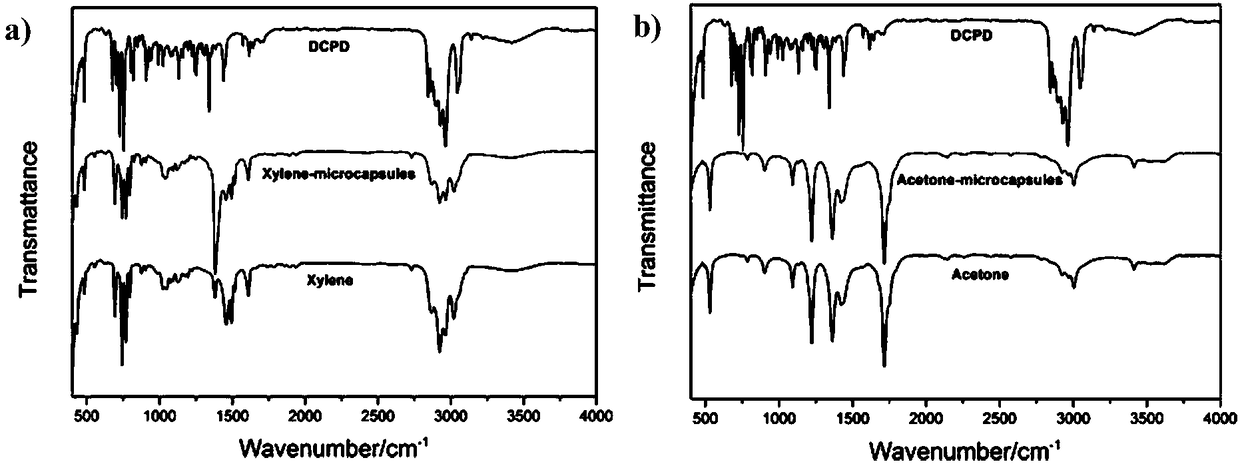

[0033] (1) Preparation of polystyrene (PS) balls

[0034] Add 3 mL of styrene, 0.1 g of oleic acid and 140 mL of deionized water into a three-necked flask, place on a constant temperature magnetic stirrer at 800 r / min and stir for 1 h. Then, 0.2 g of potassium peroxodisulfate (KPS) was added, and the three-neck flask was transferred to a collector-type constant-temperature heating magnetic stirrer to raise the temperature to 70° C., and stirred for 5 h under nitrogen protection. After the reaction, cool to room temperature, centrifuge and wash four times in a desktop centrifuge, wherein the second time is washed with ethanol, and the remaining three times are washed with deionized water to obtain polystyrene (PS) balls, which are dispersed at 60 mg / mL in in aqueous solution.

[0035] (2) Preparation of phenolic resin-embedded polystyrene (PS@PF) spheres

[0036] Mix 1.5mL polystyrene ball solution with 60mL deionized water and add it into a beaker, place it in an ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com