Preparation method of a niobium-based surface oxidation-resistant self-healing cr/nicr coating

An anti-oxidation and self-healing technology, which is applied in coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems of lack of protection, damage to the performance of welding parts of structural parts, etc., and achieve the reduction of coating Structural defects, ensuring compactness and oxidation resistance, and reducing the effect of damage on the overall performance of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

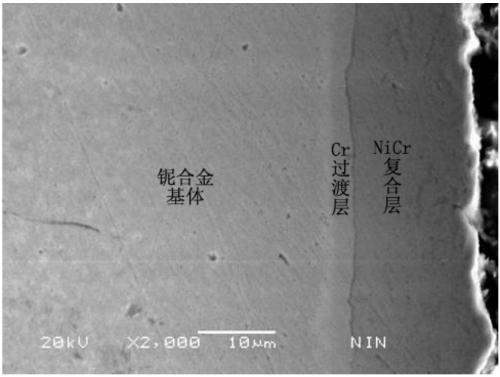

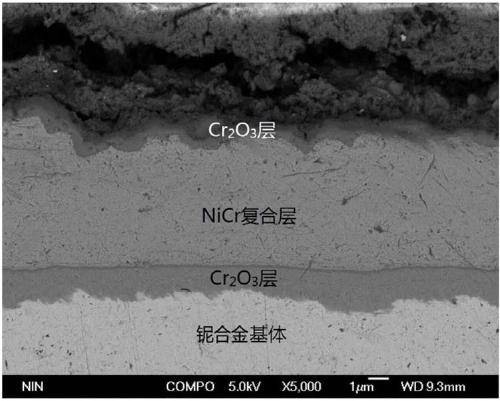

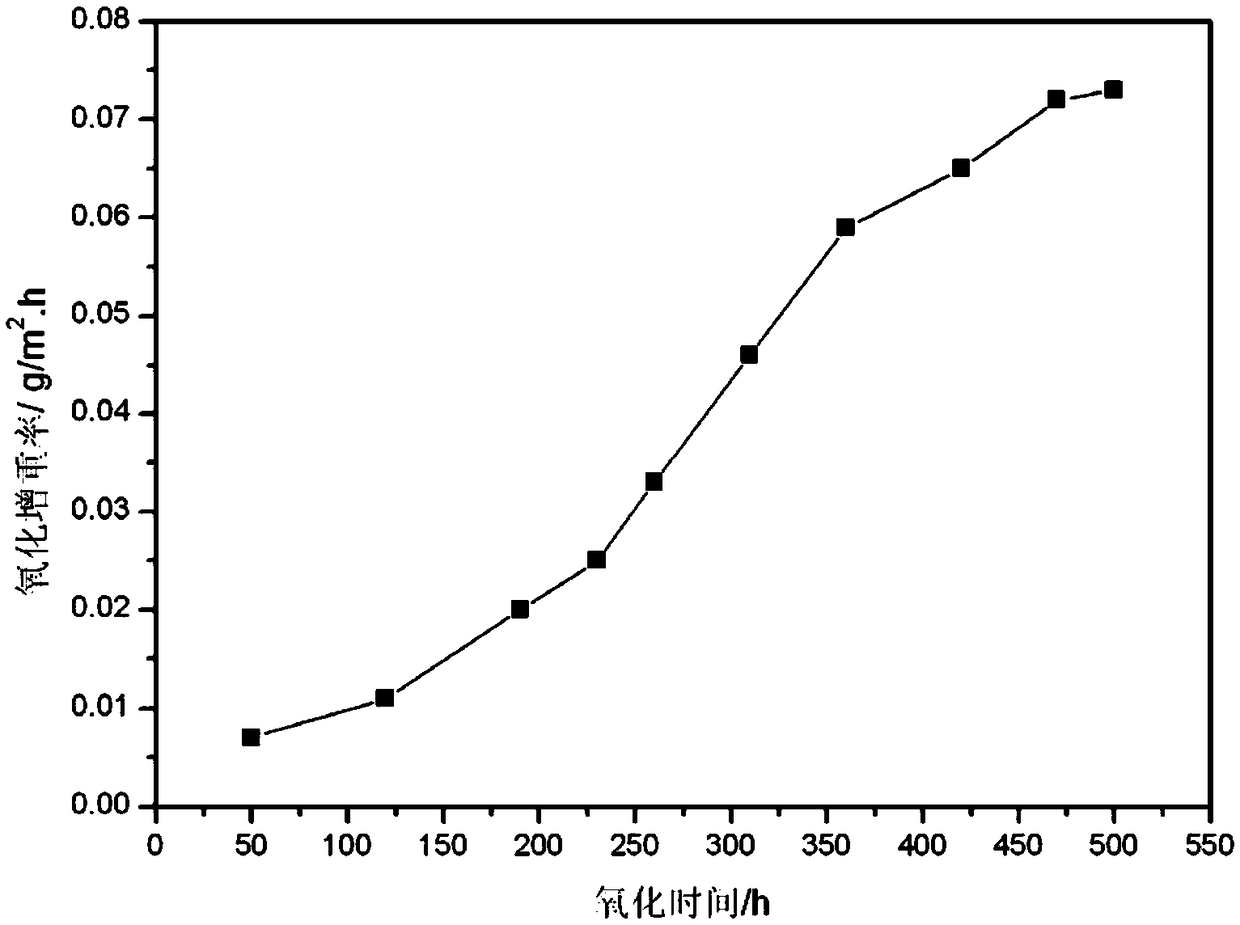

[0027] The method for preparing the anti-oxidation self-healing Cr / NiCr coating on the surface of Nb-1Zr alloy in this embodiment comprises the following steps:

[0028] Step 1. Put the surface of the Nb-1Zr alloy into the vacuum chamber of the vacuum plasma physical vapor deposition equipment after surface pickling, polishing, sandblasting and ultrasonic anhydrous ethanol cleaning and drying, and argon gas is introduced into the vacuum chamber When the indoor air pressure is 0.05Pa, open the arc Cr target, and use the arc Cr target at a power density of 15W / cm 2 Cr ions produced by discharge under certain conditions carry out ion bombardment sputtering cleaning on the surface of the Nb-1Zr alloy; the bias voltage of the Nb-1Zr alloy during the ion bombardment sputtering cleaning process is -1200V, and the time for sputtering cleaning is 1min;

[0029] Step 2. After the ion bombardment and sputtering described in step 1 is completed, argon gas is introduced into the vacuum cha...

Embodiment 2

[0037] The method for preparing the oxidation-resistant self-healing Cr / NiCr coating on the surface of C103 niobium-hafnium alloy in this embodiment comprises the following steps:

[0038] Step 1. Place the surface of the C103 niobium-hafnium alloy in the vacuum chamber of the vacuum plasma physical vapor deposition equipment after surface pickling, polishing, sandblasting, ultrasonic anhydrous ethanol cleaning, and drying, and argon gas is introduced into the vacuum chamber When the indoor air pressure is 0.1Pa, open the arc Cr target, and use the arc Cr target at a power density of 5W / cm 2 Cr ions produced by discharge under certain conditions carry out ion bombardment sputtering cleaning on the surface of C103 niobium-hafnium alloy; in the ion bombardment sputtering cleaning process, the bias voltage of C103 niobium-hafnium alloy is -1000V, and the time of sputtering cleaning is 2min;

[0039] Step 2. After the ion bombardment and sputtering described in step 1 is cleaned, ...

Embodiment 3

[0047] The method for preparing the anti-oxidation self-healing Cr / NiCr coating on the surface of Nb-W alloy in this embodiment comprises the following steps:

[0048] Step 1. Put the surface of the Nb-W alloy in the vacuum chamber of the vacuum plasma physical vapor deposition equipment after surface pickling, polishing, sandblasting and ultrasonic anhydrous ethanol cleaning and drying, and argon gas is introduced into the vacuum chamber When the indoor air pressure is 0.01Pa, open the arc Cr target, and use the arc Cr target at a power density of 20W / cm 2 The Cr ions produced by the discharge under certain conditions carry out ion bombardment sputtering cleaning on the surface of the Nb-W alloy; the bias voltage of the Nb-W alloy during the ion bombardment sputtering cleaning process is -800V, and the time for sputtering cleaning is 3min; -W alloy temperature is room temperature 25°C;

[0049] Step 2. After the ion bombardment and sputtering described in step 1 is cleaned, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com