A kind of environment-friendly weather-resistant self-layering single-component waterproof coating and preparation method thereof

A waterproof coating and self-layering technology, applied in the field of architectural waterproof coatings and waterproof coatings, can solve the problems of shortened coating life, short service life, poor weather resistance, etc. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

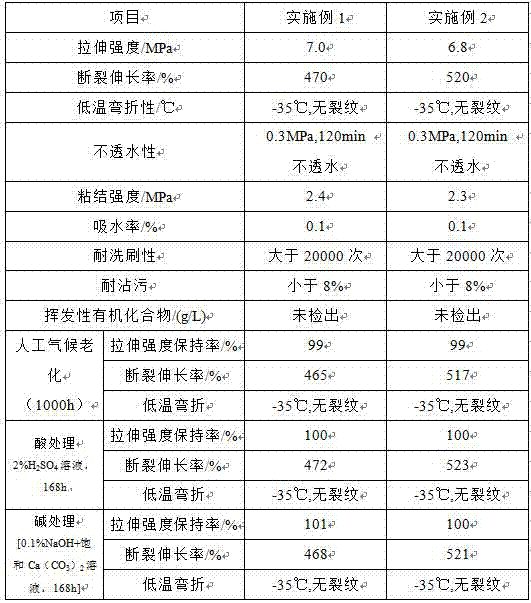

Embodiment 1

[0035] Example 1 An environmentally friendly weather-resistant self-layering one-component waterproof coating

[0036] 1. Raw materials of waterproof coating

[0037] The raw materials of the waterproof coating include, in parts by mass: 65 parts of water-based polyurethane emulsion, 35 parts of water-based polyurethane modified fluorocarbon resin emulsion, 0.3 part of bactericide, and 1 part of defoamer.

[0038] (1) The water-based polyurethane emulsion includes the following components by mass:

[0039] 30 parts of polyether diol, 20 parts of polyether triol, 22 parts of isophorone diisocyanate, 0.3 part of catalyst, 2.5 parts of 2,2-dimethylol propionic acid, 1 part of hydroxyethyl methacrylate , 0.3 parts of emulsifier, 100 parts of deionized water;

[0040] The relative molecular mass of the polyether diol is 2000;

[0041] The model of described polyether trihydric alcohol is 330N;

[0042] The catalyst is T-12;

[0043] The emulsifier is OP-10.

[0044] (2) The w...

Embodiment 2

[0072] Example 2 An environmentally friendly weather-resistant self-layering one-component waterproof coating

[0073] 1. Raw materials of waterproof coating

[0074] The raw materials of the waterproof coating include, in parts by mass: 70 parts of water-based polyurethane emulsion, 30 parts of water-based polyurethane modified fluorocarbon resin emulsion, 0.3 part of bactericide, and 0.8 part of defoamer.

[0075] (1) The water-based polyurethane emulsion includes the following components by mass:

[0076] 30 parts of polyether diol, 20 parts of polyether triol, 22 parts of isophorone diisocyanate, 0.3 parts of catalyst, 2 parts of 2,2-dimethylol propionic acid, 1.5 parts of hydroxyethyl methacrylate , 0.3 parts of emulsifier, 100 parts of deionized water;

[0077] The relative molecular mass of the polyether diol is 2000;

[0078] The model of described polyether trihydric alcohol is 330N;

[0079] The catalyst is T-12;

[0080] The emulsifier is OP-10.

[0081] (2) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com