Preparation method for LED perpendicular structure

A technology of vertical structure and LED epitaxial wafer, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of GaN surface treatment difficulties, increased loss of thin film defects, and restrictions on large-scale applications, and achieve low cost and high-quality devices. Efficiency improvement, simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

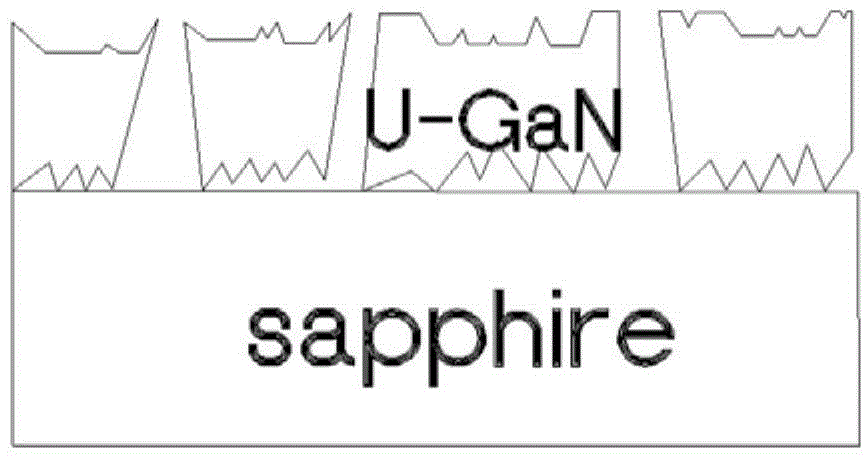

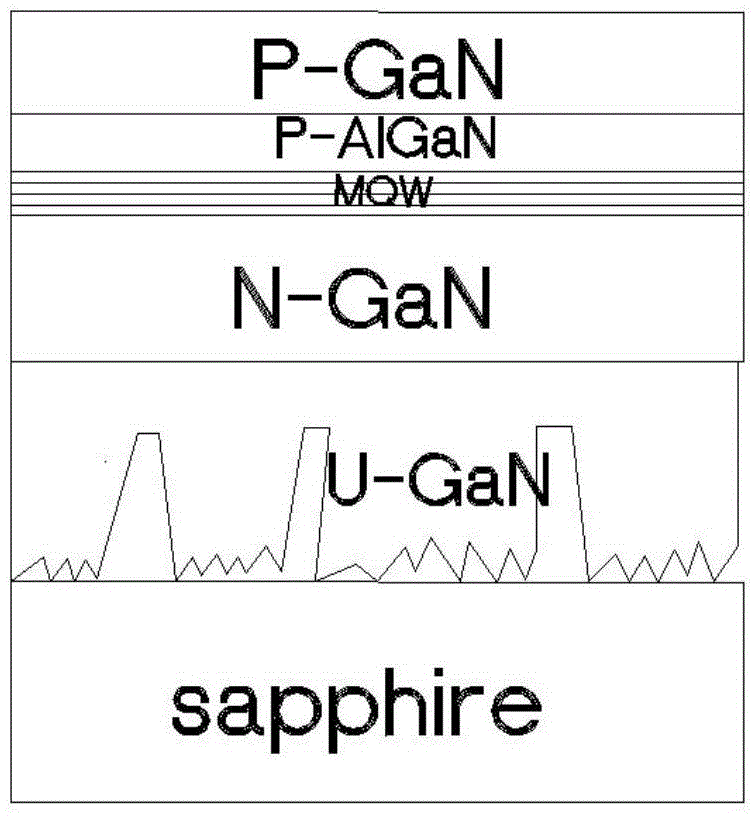

[0038] The main feature of the present invention is: after U-GaN grows, carry out wet etching (KOH or H 3 PO 4Wet etching); etch through GaN defects (GaN growth on a heterogeneous substrate (sapphire) itself will generate a large number of defects) to the GaN / sapphire interface, and etch in both directions, followed by The wafer enters the epitaxial equipment again for GaN epitaxial growth, and the regrown GaN will directly grow GaN on the etched GaN instead of on the sapphire. In this way, part of the stress of GaN is released, and this process will leave an inverted pyramid structure at the GaN at the sapphire interface, so that a point contact is formed between GaN and sapphire, which is conducive to the subsequent peeling of the epitaxial layer to form a vertical structure. Prepare a reflector (Ti / Ni / Ag or Ti / Ni / Al) on the surface of the P-GaN epitaxial layer; finally, use a high-temperature metal bonding process to bond the P-GaN (electrode) to a silicon or copper or tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com