Preparation method for low-cost GaN-based light emitting diode

A light-emitting diode, gallium nitride-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as being unsuitable for high current density conditions, and achieve the effects of avoiding current blocking effects, reducing manufacturing costs, and improving luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

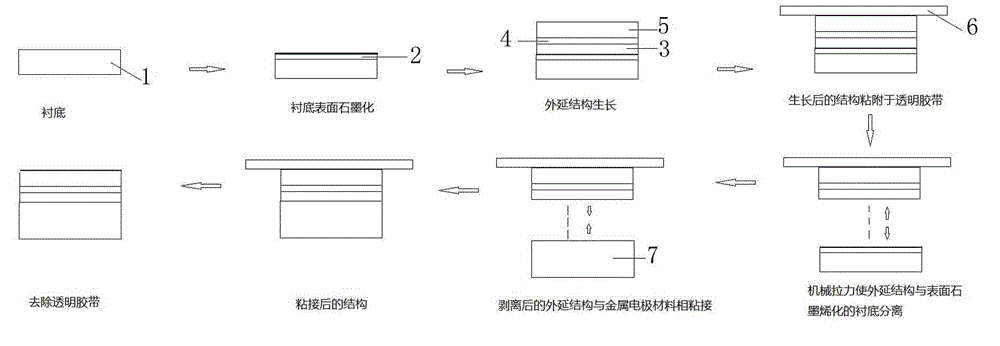

[0021] The preparation method of LED structure described in embodiment 1, concrete steps are as follows:

[0022] 1) When the reaction temperature of the crystalline flake TiC material reaches 850°C, the reaction temperature is kept at 850°C for 15 minutes to realize the detitanium removal process on the surface, then the chlorine gas source is turned off, and argon gas is passed in, and the temperature is still maintained at 850°C for 20 minutes to achieve Grapheneization of the surface layer, the number of graphene layers is 6 layers, and the graphene is in the form of undulating wrinkled surfaces, with a height difference within 15nm; the thickness of the thin-sheet TiC substrate can be selected from 300um to 1mm;

[0023] 2) Put the flaky TiC substrate 1 material whose surface has been grapheneized into the MOCVD reaction chamber to sequentially grow the n-type doped layer, the multi-quantum well light-emitting layer and the p-type doped layer epitaxial structure. The grow...

Embodiment 2

[0028] The preparation method of LED structure described in embodiment 2, concrete steps are as follows:

[0029] 1) When the reaction temperature of amorphous TiC flakes reaches 500 °C, chlorine gas is passed in for 10 minutes to realize the detitanium removal process on the surface, then the chlorine gas source is turned off, argon gas is introduced, and the temperature is raised to 850 °C to keep 15 minutes to realize the grapheneization of the surface layer; the number of graphene layers is 3 layers, and the graphene is in the shape of undulating wrinkled surfaces, and the height difference of the fluctuations is within the range of 10nm; the thickness of the flake TiC substrate can be selected from 300um to 1mm;

[0030]2) Put the flaky TiC substrate 1 material whose surface has been grapheneized into the MOCVD reaction chamber to sequentially grow the n-type doped layer, the multi-quantum well light-emitting layer and the p-type doped layer epitaxial structure. The growt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com