Endoscope optical system and manufacture device and method thereof

A technology for optical systems and preparation devices, applied in the fields of endoscopy, medical science, diagnosis, etc., can solve the problems of high manufacturing cost of optical components, limited manufacturing cost of endoscopes, high assembly, etc., and achieve high processing efficiency and improved smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

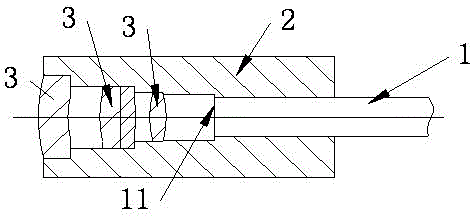

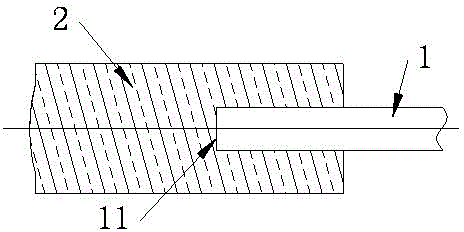

[0027] Example 1: Endoscope Optical System

[0028] see figure 2 The shown endoscopic optical system comprises a plastic optical fiber 1 and an integral lens 2 formed by resin injection molding, the left end of the plastic optical fiber is coaxial with the lens and extends into the rear end of the lens to form an integral body and extends into the lens The end face 11 of the left end of the inner plastic optical fiber is perpendicular to the optical axis of the lens.

[0029] The resins shown can be polyalkylsilicone resins (such as polymethylsilicone, polyethylsilicone), polyarylsilicone resins, or polyalkylarylsilicone resins (such as polymethylphenylsilicone resin, polyethylphenyl silicone resin). Plastic optical fiber (POF) is made of highly transparent polymers such as polystyrene (PS), polymethyl methacrylate (PMMA) or polycarbonate (PC) as the core material, and PMMA or fluoroplastic as the skin material. Class optical fiber (optical fiber), belongs to the prior art...

Embodiment 2

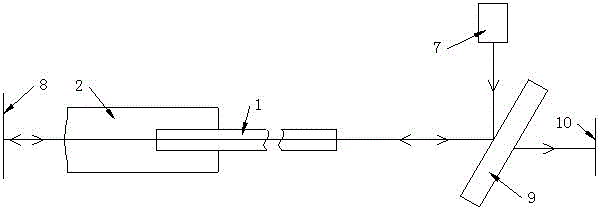

[0031] Embodiment 2: the preparation device of endoscope optical system

[0032] see Figure 4 In the preparation device of the endoscope optical system shown, the plastic optical fiber 1 beyond the end face of the flange is fixed on the flange 3; the lens mold 5 is connected with the end face 31 of the flange, and the end face of the flange is used to inject resin into the lens mold 5 to form a lens The mold cavity 51 is closed, and the plastic optical fiber 1 coaxial with the mold cavity extends into the rear end of the mold cavity, and two gates 52 for resin injection are opened on the wall of the mold cavity radially opposite to the plastic optical fiber inserted into the mold cavity. . The two gates are symmetrical to the axis of the plastic optical fiber.

Embodiment 3

[0033] Embodiment 3: the preparation method of endoscope optical system

[0034] The preparation device described in Example 2 was used. First fix the plastic optical fiber 1 on the center of the flange 3, see Figure 5 , the plastic optical fiber beyond the end face of the flange extends into the hole 61 opened on the fixing plate 6 that is equal to the outer diameter of the plastic optical fiber, and the fixing plate 6 is contacted and fixed with the end face 31 of the flange, and then the end face of the fixing plate is milled with a milling machine. 62 for milling, of course, the end face of the plastic optical fiber is also milled, see Figure 6 , and then remove the fixing plate. Then the flange 3 fixed with the plastic optical fiber 1 is fixedly connected with the lens mold 5, see Figure 7 , the flange end face 31 closes the mold cavity 51, and the plastic optical fiber 1 extends into the rear end of the mold cavity 51. After the silicone resin is injected into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com