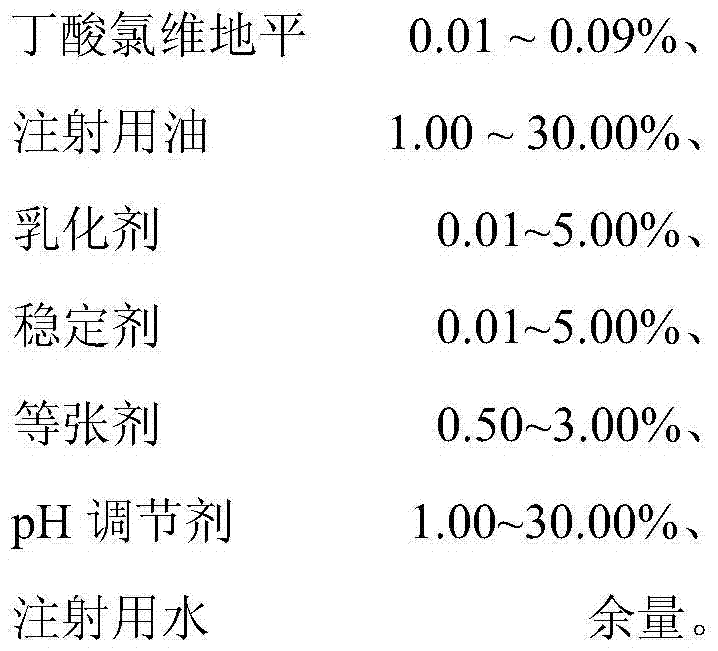

Clevidipine butyrate lipid microsphere injection and preparation method thereof

A technology of chlorvinyl butyrate and dipine fat, which is applied in the direction of pharmaceutical formula, emulsion delivery, medical preparations containing active ingredients, etc., can solve the problems of cumbersome steps, aggregation and sedimentation, large particle size, etc., and achieve uniform particle size distribution , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Effect of raw materials on clevidipine butyrate lipid microsphere injection

[0028]

[0029] Preparation method: 1) Water phase: disperse the isotonic agent in the prescribed amount in water for injection, stir until completely dissolved, and adjust the pH to 8.0 with 0.1mol / L NaOH solution;

[0030] 2) Oil phase: weigh the prescribed amount of oil for injection and stabilizer, preheat at 70°C for 2 minutes; add the prescribed amount of clevidipine butyrate, shake well and mix; add emulsifier, and use high-speed dispersion at 70°C Machine shear until the emulsified oil is completely dissolved;

[0031] 3) Slowly add the oil phase to the water phase, add water, and shear with a high-speed disperser at 20,000 rpm for 10 times, each time for 1 min, to obtain stable colostrum.

[0032] 4) Add it into the micro-jet, perform high-pressure homogenization, the pressure of high-pressure homogenization is 15,000 psi, and homogenize 12 times.

[0033] 1. Choice of ...

Embodiment 2

[0053] Example 2 Effect of process conditions on clevidipine butyrate lipid microsphere injection

[0054] 1. Effect of emulsification temperature

[0055] The emulsification temperature refers to the temperature when the oil phase and the water phase are mixed and sheared. The emulsification temperature can affect the fluidity of the oil phase and the water phase, the stability of the drug and the behavior of the surfactant during emulsification. Taking particle size, PDI, drug content and Zeta potential as the main evaluation indicators, the oil-water two-phase was preheated before mixing and shearing. The temperature was set at 40°C, 50°C, 60°C, 70°C, 80°C and 90°C. Effect of emulsification temperature on the physical and chemical stability of clevidipine butyrate lipid microspheres. The results are shown in Table 5.

[0056] Table 5 Effect of emulsification temperature on clevidipine butyrate lipid microspheres

[0057]

[0058] It can be seen from Table 5 that when t...

Embodiment 3

[0076] Example 3 Clevidipine Butyrate Liposphere Injection

[0077] (1) The formula is as follows

[0078]

[0079] (2) Preparation method

[0080] 1) Water phase: Disperse the prescribed amount of glycerin in water for injection and stir until completely dissolved. Adjust the pH to 8.0 with 0.1mol / L NaOH solution.

[0081] 2) Oil phase: Weigh the prescribed amount of soybean oil and oleic acid for injection, preheat to 70°C; add the prescribed amount of clevidipine butyrate, shake well and mix; add soybean lecithin, and use a high-speed disperser to cut to Soy lecithin is all dissolved.

[0082] 3) Slowly add the oil phase to the water phase, add water to 100 mL, and use a high-speed disperser at 20,000 rpm to shear 10 times, 1 min each time.

[0083] 4) Add to the micro jet, pressure 15000psi, homogenize 12 times.

[0084] 5) Bottle it, seal it, and sterilize it at 120°C for 30 minutes.

[0085] (3) Measurement results

[0086] The average particle diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com