Multistage cross-flow rotation packed bed mass transfer and reaction equipment

A technology of cross-flow rotation and reaction equipment, which is applied in chemical methods for reacting liquids and gaseous media, chemical/physical/physical-chemical fixed reactors, chemical/physical/physical-chemical processes, etc., and can solve gas-phase interface problems No problems such as rapid update, weak gas film control strengthening effect, increased liquid phase dispersion, etc., to achieve the effect of wide gas velocity range, less liquid flooding, and faster update rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

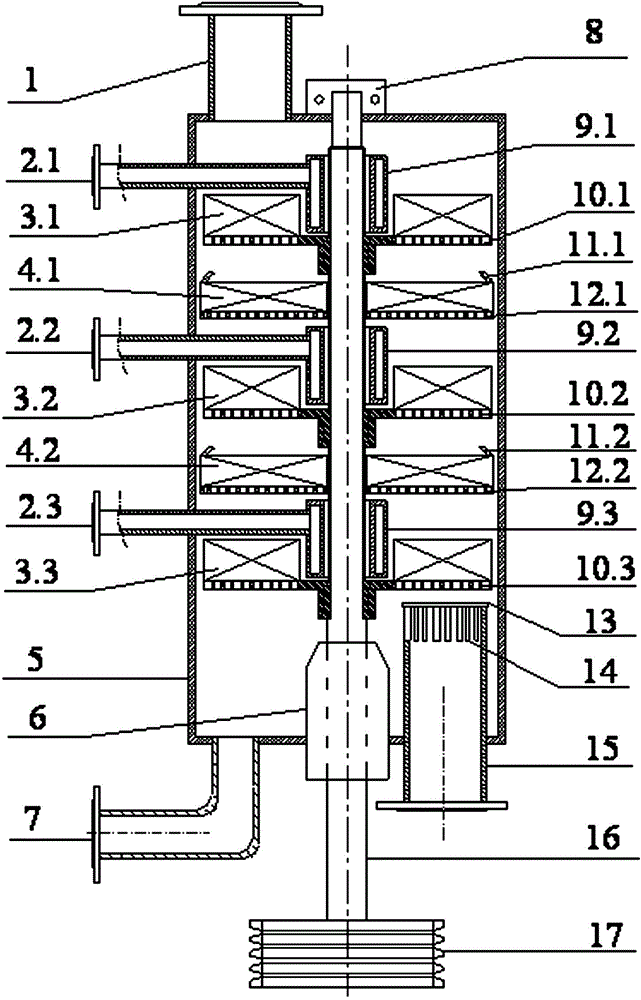

[0020] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0021] A multi-stage cross-flow rotating packed bed mass transfer and reaction equipment, including a rotating bed shell 5, a rotating shaft 16, two or more high-speed rotating packing rotors and one or more stationary packing stators, the packing rotors and The packing stators are installed alternately, coaxially arranged from top to bottom, starting from the packing rotor and ending with the packing rotor. The center of the packing rotors is equipped with a liquid distributor, which is connected to their respective liquid inlet pipes. The top of the rotating bed shell 5 Connect the exhaust pipe 1, connect the liquid outlet pipe 7 and the gas inlet pipe 15 at the bottom.

[0022] The filler stator is connected with the rotary bed housing 5, the filler rotor is connected with the rotating shaft 16, and the lower end of the rotating shaft 16 is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com