A portal-type automatic welding and gouging integrated machine for welding steel pipe rods

A technology for automatic welding and welding of steel pipes, which is applied in the field of numerical control machine tools, can solve problems such as the large current of submerged arc welding machine is not suitable for welding thin-walled workpieces, affects the quality of submerged arc welding seams, and the loss of submerged arc welding flux is large, so as to achieve reduction Welding priming process, eliminating the need for priming process, and the effect of stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

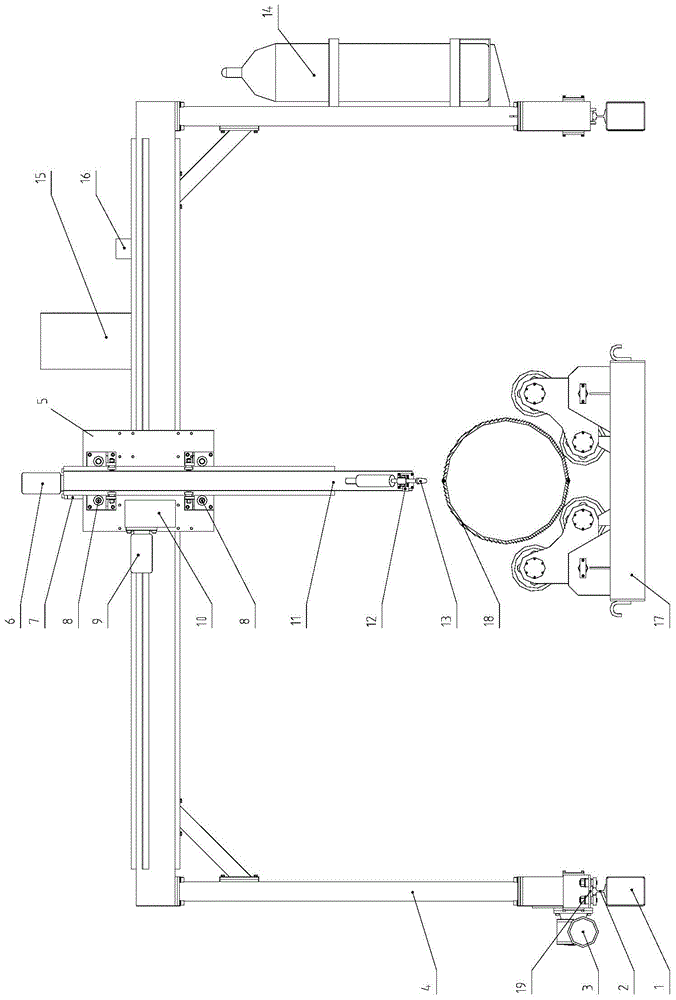

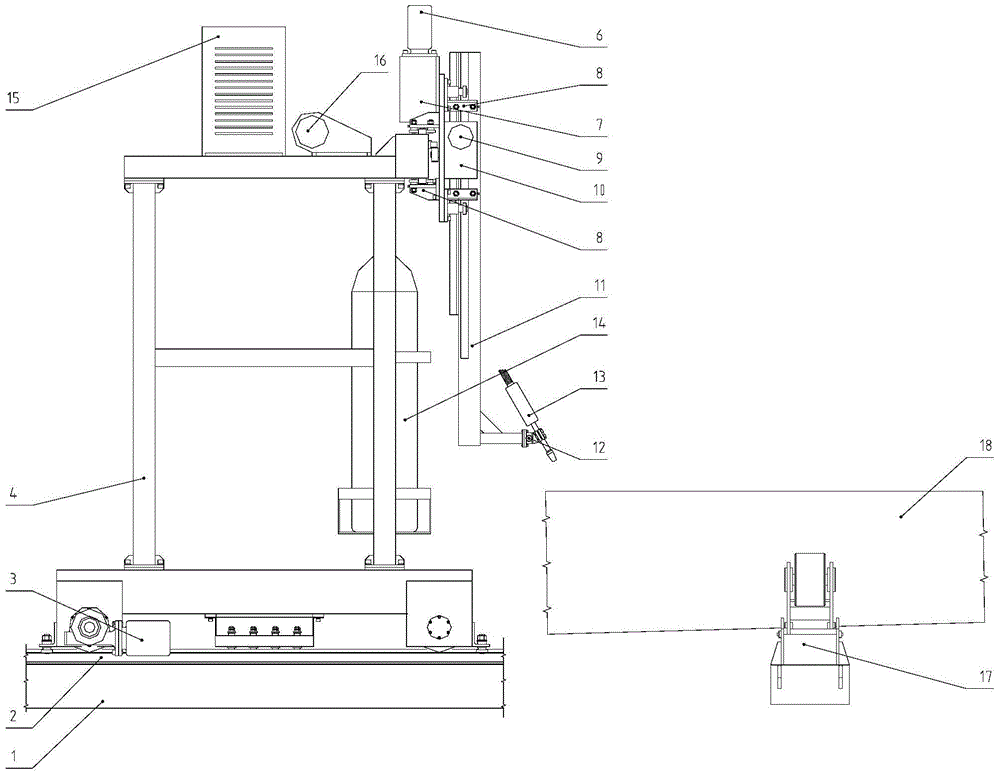

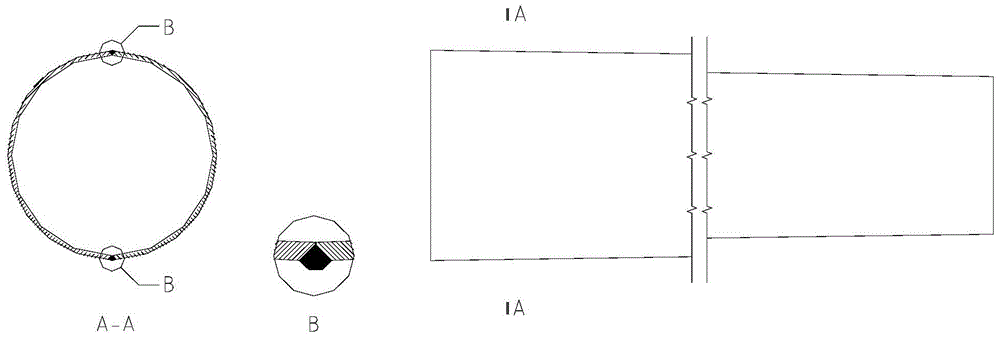

[0030] see figure 1 and figure 2 , a portal-type automatic welding and gouging integrated machine for welding steel pipe rods, including a track steel beam 1, a grooved track 2, a gantry traveling motor reducer integrated machine 3, a gantry 4, a transverse carriage 5, and a welding arm Vertical travel motor 6, welding arm vertical reducer 7, guide wheel seat 8, welding arm lateral travel motor 9, welding arm lateral reducer 10, welding arm 11, welding oscillator 12, welding torch or gouging gun 13, protection Gas cylinder 14, welder 15, wire feeder 16 and electric drum 17. Among them, the track steel beam 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com