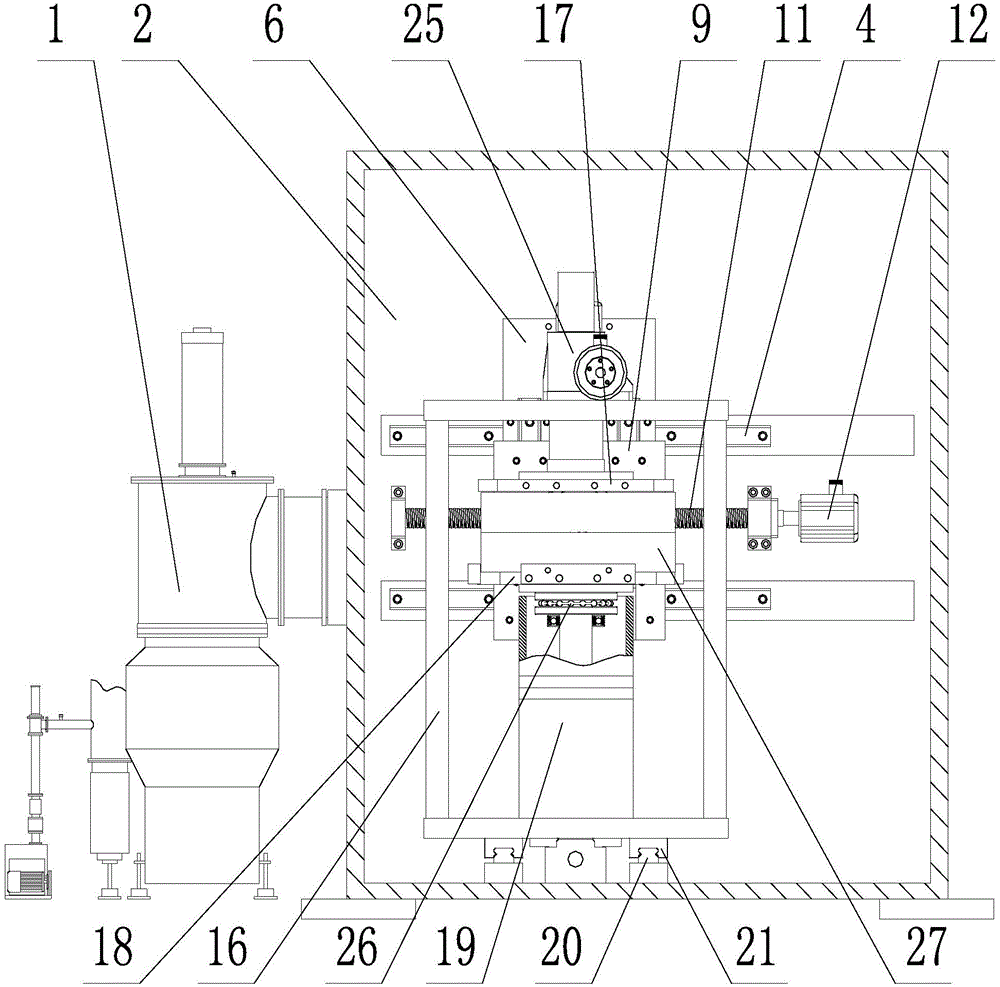

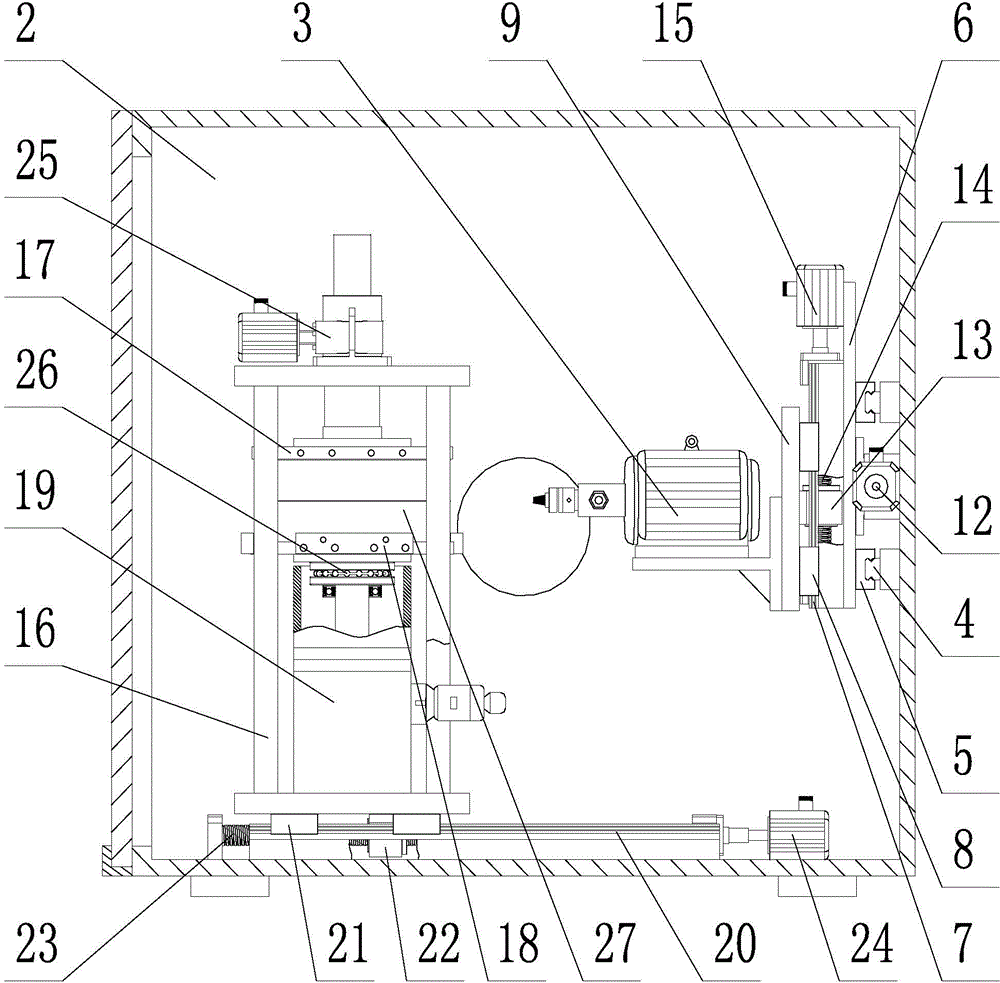

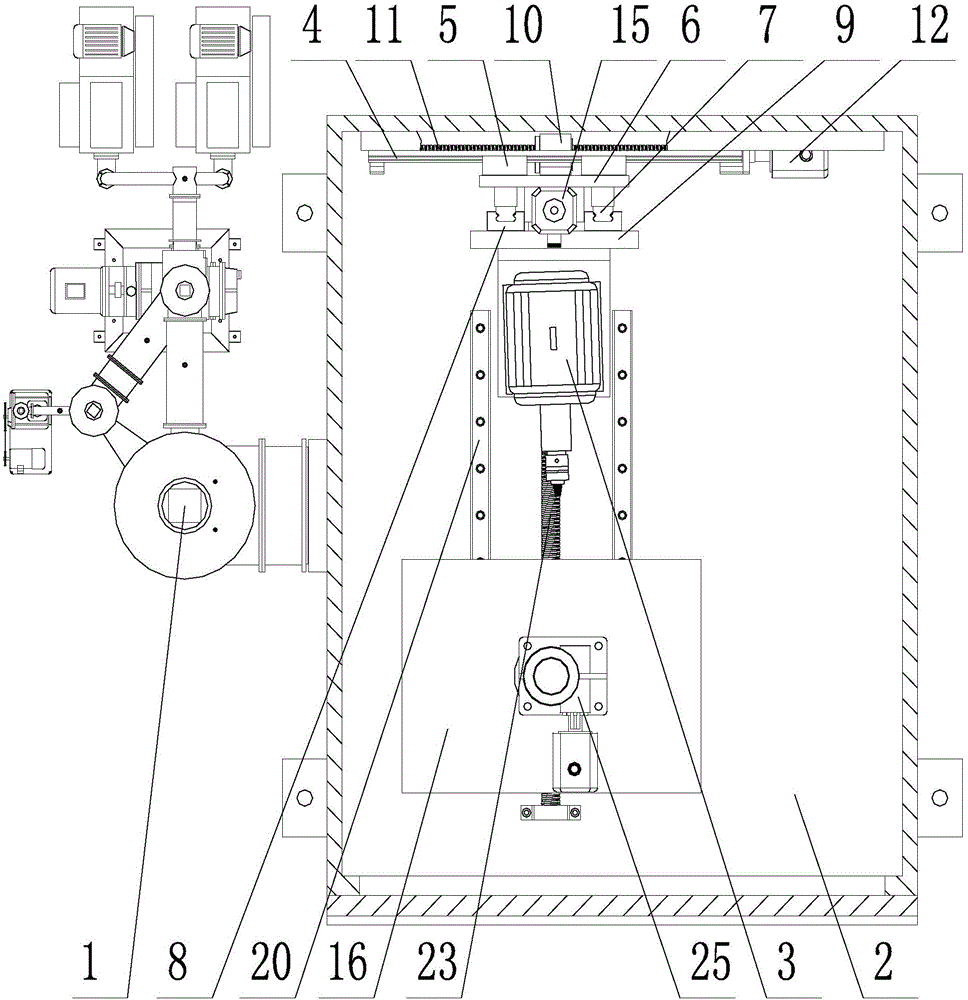

Vacuum stirring friction welding device and manufacturing method of metal composite plate

A technology of friction stir welding and friction welding, which is applied in welding equipment, metal processing equipment, metal processing, etc., can solve problems such as poor welding performance, reduced weld mechanical properties, a large number of pores and cracks, etc., to avoid oxidation and ensure the interface Combined strength, the effect of improving joint weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the metal plate 27 is two 7075 aluminum alloy plates with a size of 500mm×200mm×30mm, and the rotation centerline of the stirring head of the friction stir welding machine 3 forms an angle of 5° with the Y-axis slide rail 20 .

[0045] The method for preparing a metal composite plate using the vacuum friction stir welding device comprises the following steps:

[0046] Step 1: remove the oxide film and dirt on the surfaces to be combined and the four sides where the welds are located of the two metal plates 27;

[0047] Step 2: Superimpose the surfaces to be compounded of the two metal plates 27 relative to each other, and place them on the lower splint 18 of the workpiece fixture after aligning them around;

[0048] Step 3: Start the lifting and tightening mechanism 19, so that the metal plate 27 to be combined is firmly clamped between the upper splint 17 and the lower splint 18;

[0049] Step 4: Under the driving of the X-axis driving motor 12 and...

Embodiment 2

[0058] In this embodiment, the metal plates 27 are two AZ80 magnesium alloy plates with a size of 500mm×300mm×40mm.

[0059] The composite plate preparation method of AZ80 magnesium alloy plate is the same as embodiment 1, but the vacuum pressure in the vacuum chamber 2 is 0.03Pa; 25mm; the heating temperature of AZ80 magnesium alloy plate composite billet in the resistance furnace is 370°C, and the holding time is 30 minutes; when rolling the AZ80 magnesium alloy plate composite billet, the rolling temperature is 340°C, and the rolling speed is 0.7m / s, the total reduction rate is 60%, and the reduction rate in the first pass is 20%. Finally, a magnesium alloy composite plate with a size of 2500mm×200mm×32mm is obtained. After testing, the Z-direction tensile strength of the composite interface of the composite plate is Reach 280MPa.

Embodiment 3

[0061] In this embodiment, the metal plates 27 are two 15CrMoR high temperature resistant alloy steel plates with a carbon equivalent of 0.65 and a size of 500mm×200mm×40mm.

[0062] The composite plate preparation method of 15CrMoR high temperature resistant alloy steel plate is the same as embodiment 1, but the vacuum pressure in the vacuum chamber 2 is 0.05Pa; 10mm; the heating temperature of 15CrMoR high temperature resistant alloy steel combined billet in the resistance furnace is 1200°C, and the holding time is 60 minutes; when rolling the 15CrMoR high temperature resistant alloy steel combined billet, the rolling temperature is 1150°C, and the rolling speed is 1m / s, the total reduction rate is 50%, and the reduction rate in the first pass is 20%. Finally, a composite steel plate with a size of 1000mm×200mm×40mm is obtained. After testing, the composite interface Z-direction tensile strength of the composite steel plate reaches 530MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com