Online high-quality permanent welding-repairing construction method for high-speed railway line

A technology for high-speed railways and construction methods, which is applied to roads, manufacturing tools, welding equipment, etc., can solve the problems of high-quality permanent welding, poor adaptability, and endangering driving safety, etc., and achieves safe and stable operation process. The effect of reducing rail workload and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

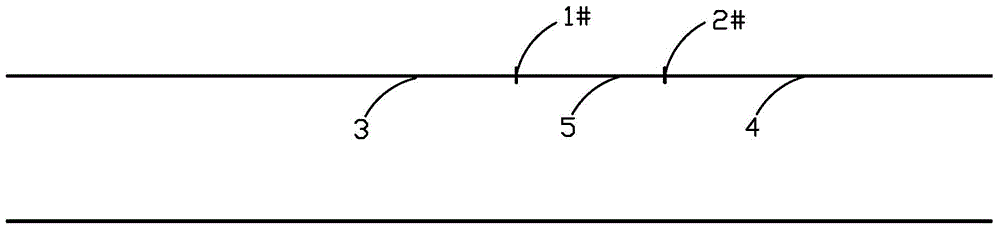

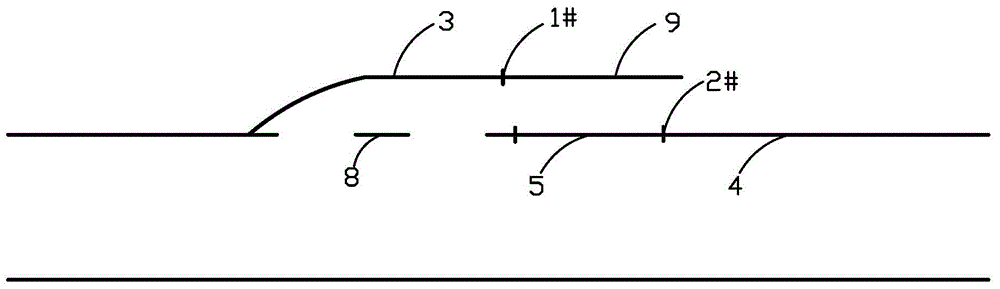

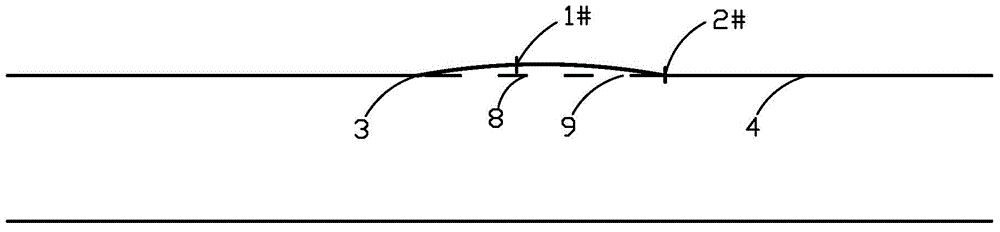

[0049] The invention discloses an on-line high-quality permanent welding reconstruction method for high-speed railway lines, including a set of key technologies for welding reconstruction using a fully automatic numerical control pneumatic rail welding machine equipped with a mobile pneumatic rail welding car:

[0050] 1. Standard working procedures for welding rails: rail sawing, rust removal, end grinding, rail pulling, welding, blast cooling, heat treatment under pressure, straightening, finishing, flaw detection.

[0051] 2. Construction rail temperature: The construction rail temperature is less than or equal to the design rail temperature. If the construction rail temperature is greater than the design rail temperature, technical measures for auxiliary coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com