Clamp for preparing graphene in double type manner and method for preparing graphene

A graphene and jig technology, which is applied to the jig for multiplying graphene preparation and the field of graphene preparation, can solve the problems of waste of resources, reduced graphene yield, easy deformation, etc., and achieves improved qualification rate, easy processing, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

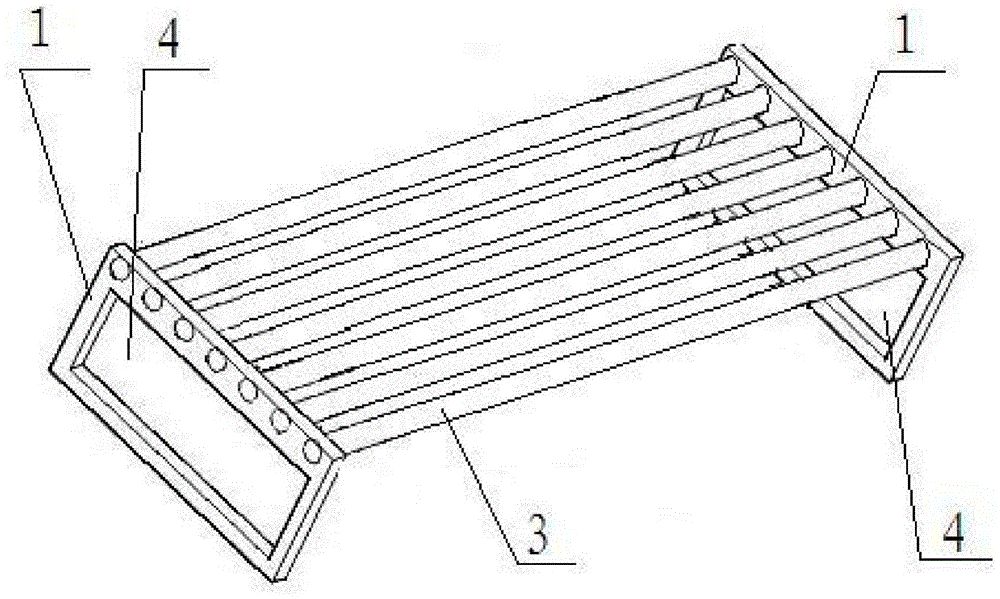

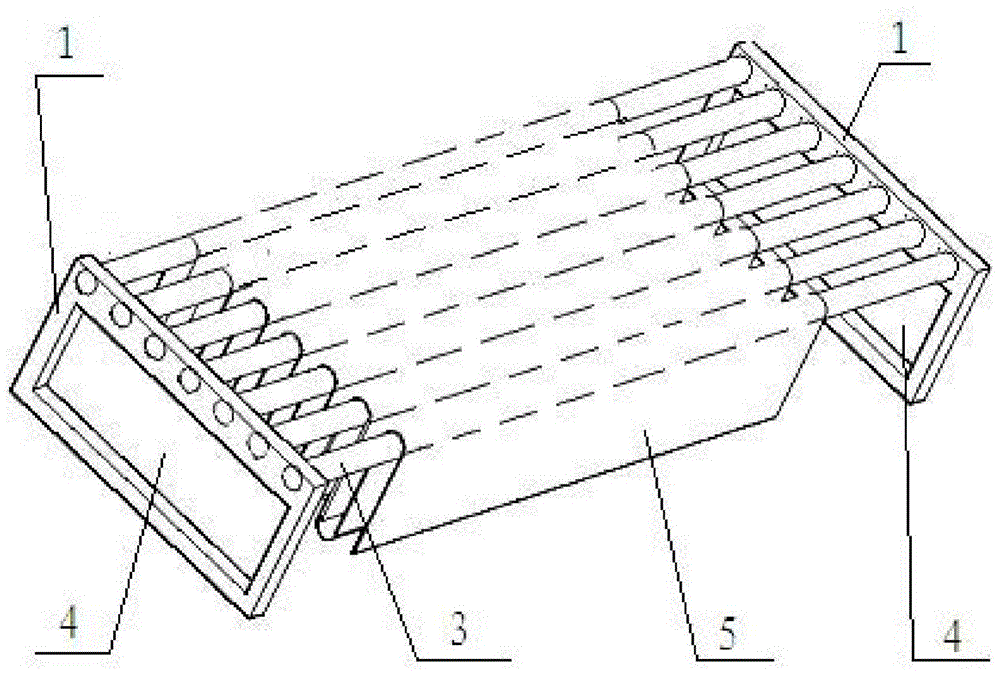

[0035] A fixture for multiplying prepared graphene, comprising two support frames 1 and several horizontal support rods 3, the two support frames 1 are relatively parallel, and the two ends of the horizontal support rods 3 are respectively connected to the two support frames The upper part of 1 is fixed, several horizontal support rods 3 are arranged parallel to each other and evenly spaced horizontally, and several horizontal support rods 3 are perpendicular to the two support frames 1 . The support frame 1 is provided with a through hole 4 . The support frame 1 has a square or trapezoidal vertical section or a semicircular bottom. The support frame 1, the horizontal support rods 3 and the growth substrate support rods 2 are made of high temperature resistant hard material or a high temperature resistant layer is spin-coated on the surface of the hard material. The distance between adjacent horizontal support rods 3 is 5-10mm.

[0036] A kind of preparation method of graphe...

specific Embodiment 2

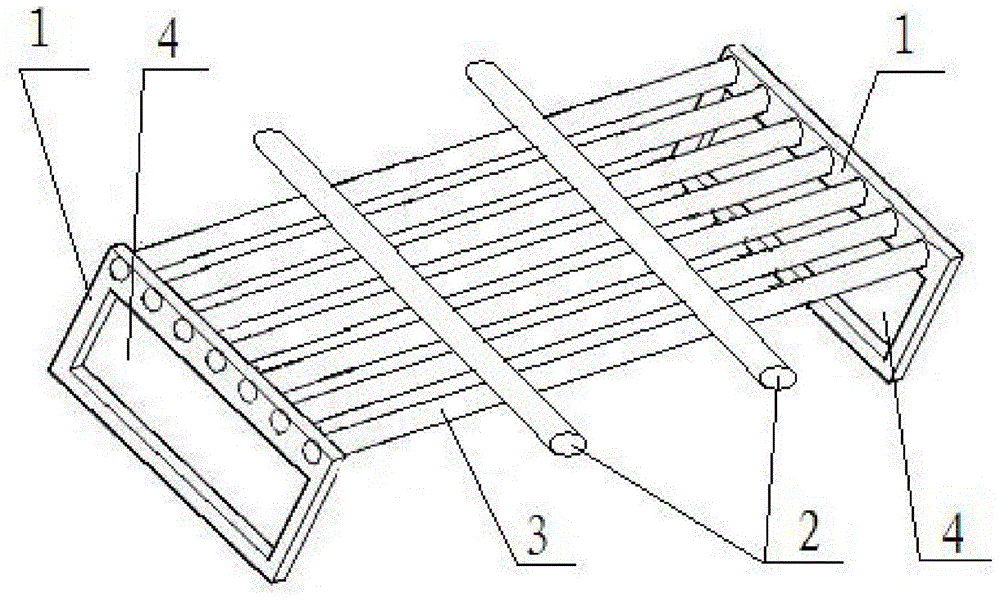

[0041] A fixture for multiplying prepared graphene, comprising two support frames 1 and several horizontal support rods 3, the two support frames 1 are relatively parallel, and the two ends of the horizontal support rods 3 are respectively connected to the two support frames The upper part of 1 is fixed, several horizontal support rods 3 are arranged parallel to each other and evenly spaced horizontally, and two growth substrate support rods 2 are arranged above several horizontal support rods 3 . The support frame 1 is provided with a through hole 4 . The support frame 1 has a square or trapezoidal vertical section or a semicircular bottom. The support frame 1, the horizontal support rods 3 and the growth substrate support rods 2 are made of high temperature resistant hard material or a high temperature resistant layer is spin-coated on the surface of the hard material. The interval between adjacent horizontal support rods 3 is 5-10mm.

[0042] A kind of preparation method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com