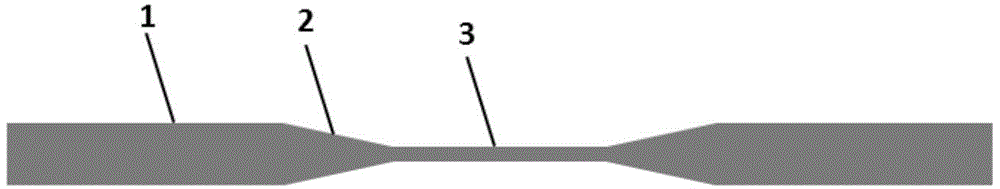

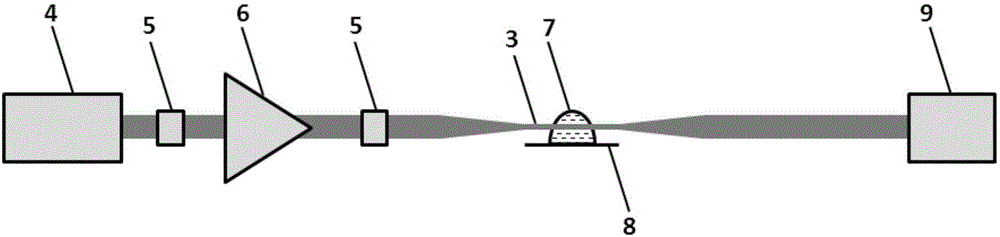

Method for efficient deposition of tungsten sulfide on side surface of tapered optical fiber

A tapered optical fiber and tungsten sulfide technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problem of high cost, achieve long action distance, increase deposition speed and deposition volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

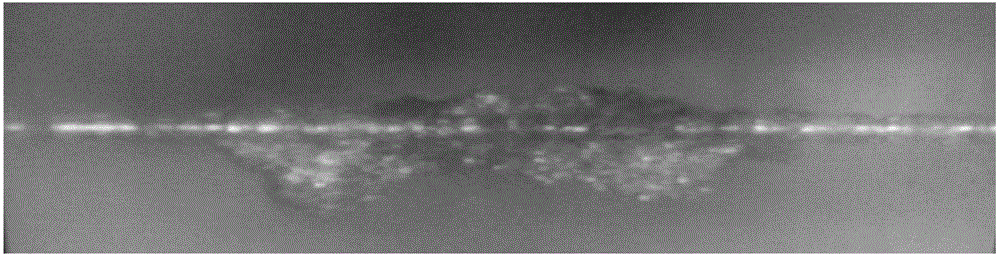

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the drawings and embodiments, but the protection scope of the present invention should not be limited by this.

[0029] A method for depositing tungsten sulfide on the side of a tapered optical fiber may specifically include the following steps:

[0030] Step 1: Disperse tungsten sulfide powder in a highly volatile dispersant to prepare a dispersion, the concentration of the tungsten sulfide dispersion is 0.0001mg / ml to 1mg / ml;

[0031] Among them, the high volatile dispersant is a solvent (such as ethanol, acetone, etc.) that enables the tungsten sulfide material particles to exist stably, is not prone to agglomeration, and has high volatility. In a preferred embodiment of the present invention, the dispersant used is ethanol.

[0032] The preferred range of the concentration of tungsten sulfide is 0.001 mg / ml to 0.1 mg / ml. If the concentration is too low, it is difficult to achieve deposition, if the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com