Heavy-metal-containing wastewater treatment and recovery method and device

A technology for heavy metals and waste water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as high energy consumption, difficulty in long-term stable operation, and difficult treatment of low-concentration waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

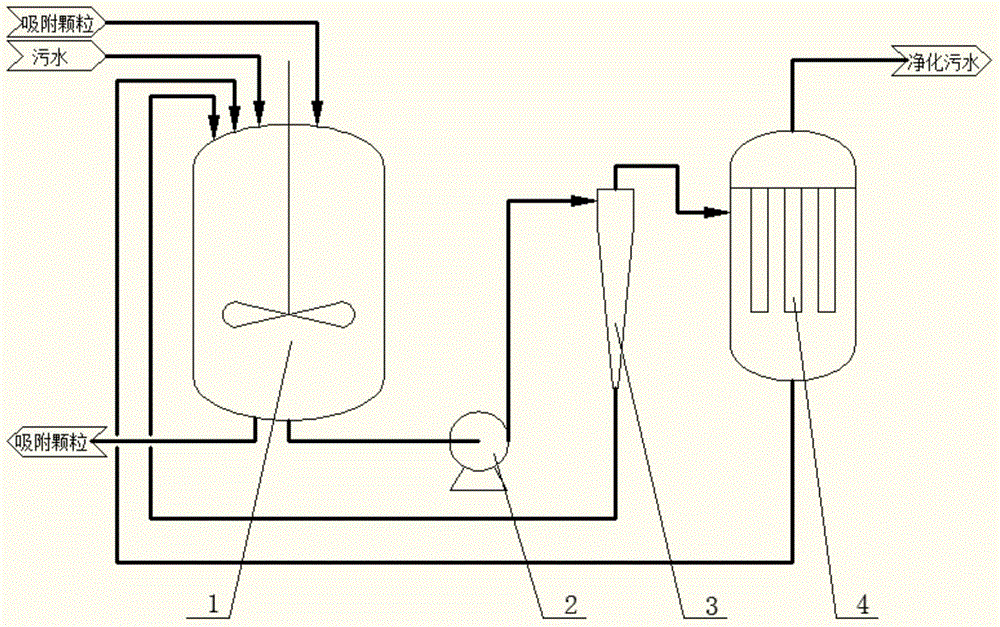

[0055] Embodiment 1: Adsorption separation of wastewater containing heavy metals

[0056] 1. Material properties

[0057] (1) Wastewater containing heavy metals: The material is industrial wastewater containing heavy metals such as cadmium, nickel, zinc, and mercury produced in industrial production. It is 2t / h, and the temperature is 60-80°C, with an average of about 70°C.

[0058] (2) Adsorption particles (macroporous weakly basic anion resin, water content is 50-60%, mass total exchange capacity> 4.8mmol / g, wet apparent density is 0.65-0.75g / ml, wet true density is 1.02-1.08 g / ml): Add 300-400g of adsorption particles per cubic meter of heavy metal-containing wastewater.

[0059] 2. Process flow

[0060] Such as figure 1 shown.

[0061] When working, the adsorption particles and heavy metal-containing wastewater are fed into the mixing device through their respective feed pipes. After being stirred evenly in the mixing device, the mixed solution is pumped into the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com