Amphoteric ionic antistatic agent for acrylonitrile butadiene styrene (ABS) and preparation method of antistatic agent

A technology of antistatic agent and zwitterion, which is applied in the field of zwitterionic polymer antistatic agent and its preparation, and can solve the problem of high resistivity

Active Publication Date: 2015-04-01

EAST CHINA UNIV OF SCI & TECH

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

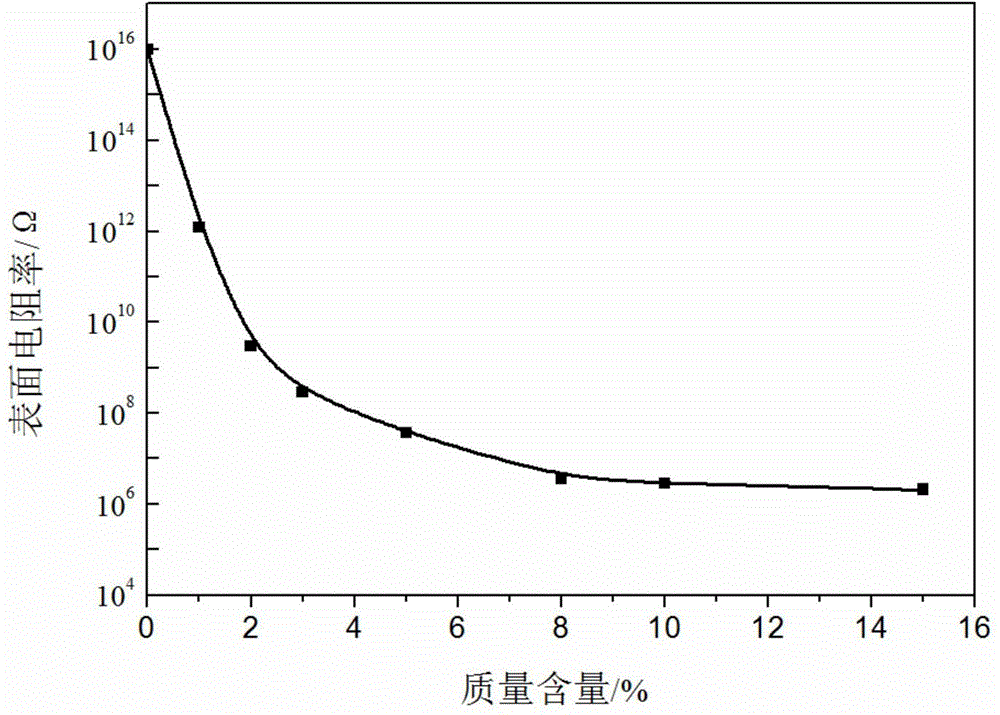

Chinese patent (CN 102719051A) adds composite antistatic agent stearamidopropyl dimethyl-β-hydroxyethyl quaternary ammonium nitrate, sodium allyl sulfonate, N,N-bis(2-hydroxyethyl )-N-(3'-dodecyloxy-2-hydroxypropyl) methyl ammonium methyl sulfate, (3-lauryl amidopropyl) trimethyl methyl sulfate ammonium to improve the antistatic performance of ABS resin , but its surface resistivity is still 10 8 Ω or more, the resistivity is still high, which cannot meet some industries that require high material resistivity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

Login to View More

Abstract

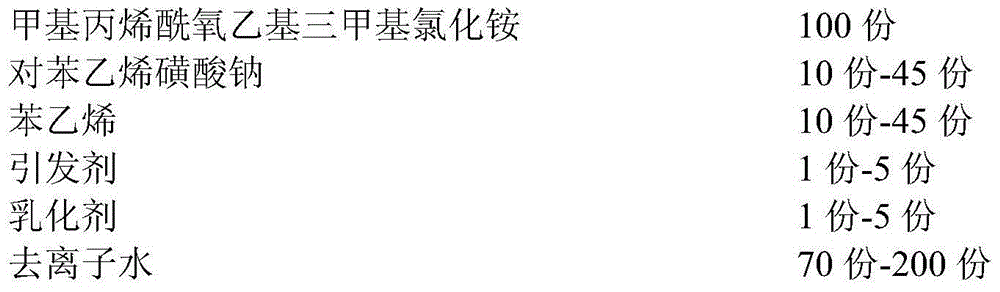

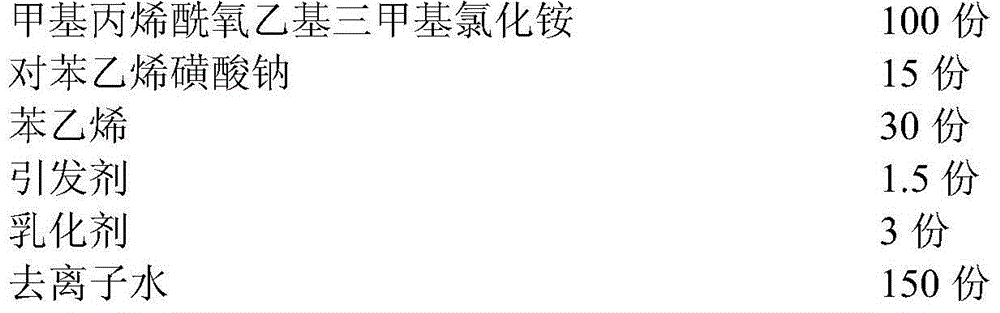

The invention relates to an amphoteric ionic antistatic agent for acrylonitrile butadiene styrene (ABS) and a preparation method of the antistatic agent. The efficient amphoteric ionic high molecular antistatic agent is synthesized from three monomers, namely methyl acrylyl ethyl trimethyl ammonium chloride, sodium p-styrene sulfonate and styrene, by virtue of a free radical emulsion copolymerization process. Applied to an ABS material, the amphoteric ionic antistatic agent prepared by the invention has the advantages of being low in surface resistance, durable in antistatic action, light in color and good in heat resistance; the surface resistivity of the ABS material is reduced to 106-107 omega; the antistatic effect is significantly improved compared with those of conventional small molecular and high molecular antistatic agents; and the antistatic agent disclosed by the invention is easy to synthesize, free from toxicity and pollution, moderate in cost and good in application prospect.

Description

technical field [0001] The invention relates to a zwitterionic polymer antistatic agent and a preparation method thereof, in particular to a zwitterionic antistatic agent which can be used for ABS resin and a preparation method thereof. Background technique [0002] Nowadays, with the increasing development of science and technology, a single polymer material can no longer meet people's requirements for all aspects of material performance, and more and more people pay more and more attention to improving the performance of materials through polymer blending modification. ABS (terpolymer of styrene, butadiene, and acrylonitrile) is widely used in industrial fields such as machinery, automobiles, and electronic appliances due to its excellent mechanical properties, temperature resistance, and easy processing. However, its high surface resistivity and volume resistivity are easy to generate static electricity after friction, and it is not easy to eliminate, which seriously affe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F220/34C08F212/14C08F212/08C08F2/28C08F2/26C08F2/30C08L55/02C08L33/14

Inventor 汪济奎张帝漆李申喆郭卫红苏娜周旭蔡婉萍

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com