Colour master batch for TPU film and preparation method thereof

A color masterbatch and film technology, applied in the field of color masterbatch, can solve the problems of difficult control, poor color fading, poor dispersion uniformity, etc., and achieve the effect of not easy to fade, stable color, and improve dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

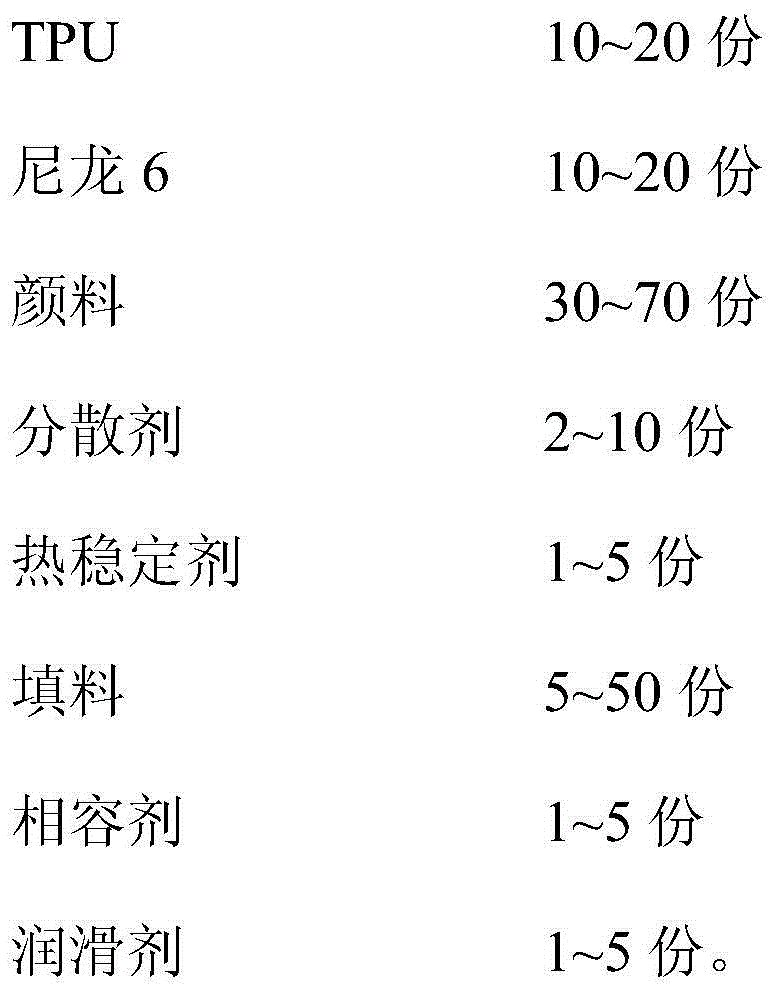

[0035] A kind of color masterbatch for TPU film, described color masterbatch is mainly prepared by following raw material by weight part:

[0036]

[0037] The dispersant is oxidized polyethylene wax.

[0038] The heat stabilizer is a sulfur-containing antioxidant, and the sulfur-containing antioxidant is 2,4-bis-(n-octylthiomethylene)-6-methylphenol.

[0039] The filler is crystalline silica.

[0040] The compatibilizer is polyethylene grafted maleic anhydride and polypropylene grafted maleic anhydride.

[0041] The lubricant is a saturated hydrocarbon lubricant.

[0042] The preparation method of color masterbatch for TPU film as described above, described method comprises the following steps:

[0043] The ingredients in the formulation amount are mixed in a high-speed mixer for 15 to 30 minutes, then extruded by a twin-screw extruder, granulated, and dried to obtain a color masterbatch for TPU film.

Embodiment 2

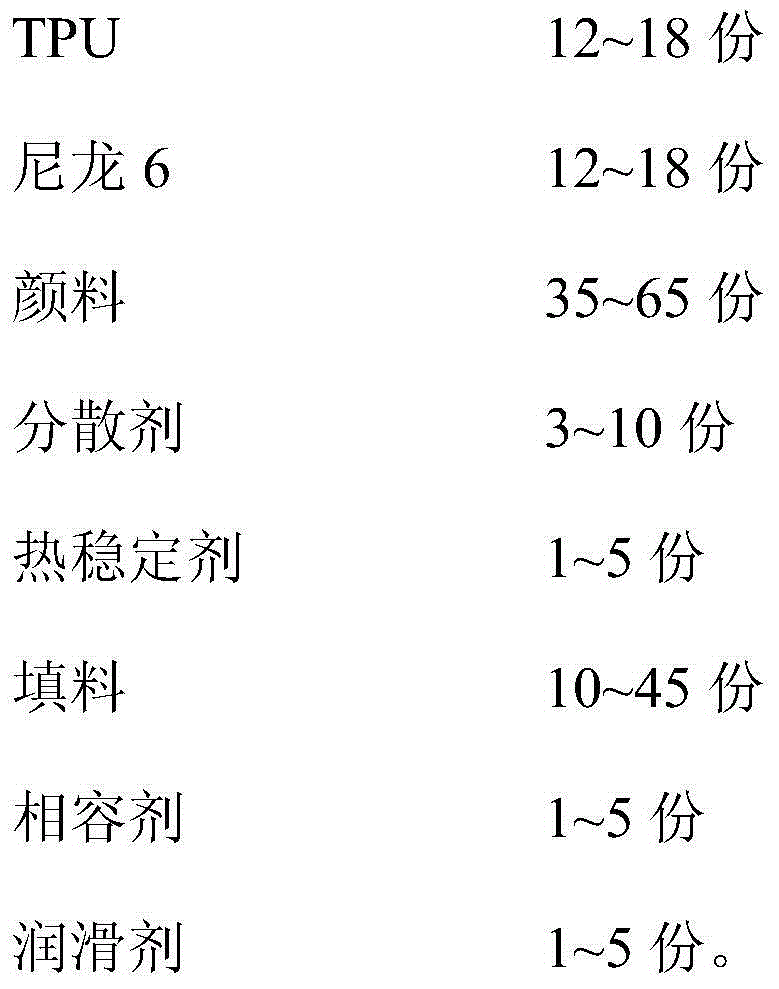

[0045] A kind of color masterbatch for TPU film, described color masterbatch is mainly prepared by following raw material by weight part:

[0046]

[0047]

[0048] The dispersant is oxidized polyethylene wax.

[0049] The heat stabilizer is a phosphite antioxidant, and the phosphite antioxidant is tris(2,4-di-tert-butylphenyl)phosphite.

[0050] The filler is a mixture of silicon carbide and strontium titanate.

[0051] The compatibilizer is polyethylene grafted maleic anhydride.

[0052] The lubricant is an aliphatic ester lubricant.

[0053] The preparation method of color masterbatch for TPU film as described above, described method comprises the following steps:

[0054] The ingredients in the formulation amount are mixed in a high-speed mixer for 15 to 30 minutes, then extruded by a twin-screw extruder, granulated, and dried to obtain a color masterbatch for TPU film.

Embodiment 3

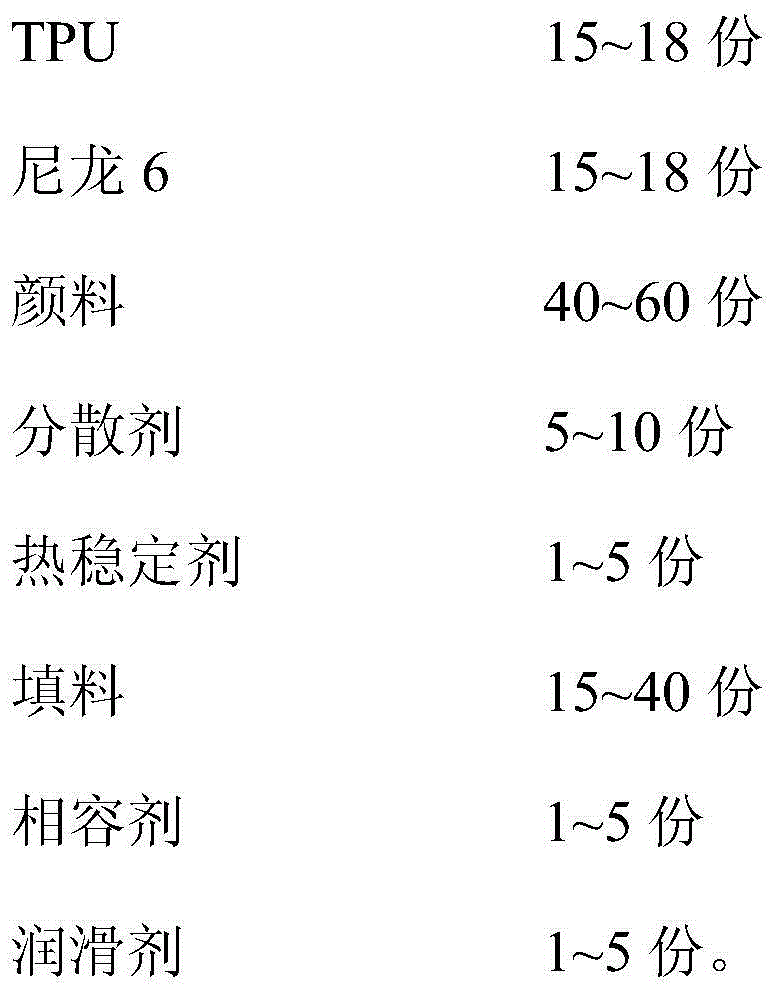

[0056] A kind of color masterbatch for TPU film, described color masterbatch is mainly prepared by following raw material by weight part:

[0057]

[0058]

[0059] The dispersant is oxidized polyethylene wax.

[0060] The heat stabilizer is a sulfur-containing antioxidant and a phosphite antioxidant, the sulfur-containing antioxidant is dilauryl thiodipropionate, and the phosphite antioxidant is pentaerythritol bisphosphite (2,4-Di-tert-butylphenyl) ester.

[0061] The filler is strontium titanate.

[0062] The compatibilizer is polypropylene grafted maleic anhydride.

[0063] The lubricants are aliphatic acids.

[0064] The preparation method of color masterbatch for TPU film as described above, described method comprises the following steps:

[0065] The ingredients in the formulation amount are mixed in a high-speed mixer for 15 to 30 minutes, then extruded by a twin-screw extruder, granulated, and dried to obtain a color masterbatch for TPU film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com