A kind of mechanized production system of calligraphy and painting paper and calligraphy and painting paper prepared therefrom

A production system, calligraphy and painting paper technology, applied in the field of calligraphy and painting paper, can solve the problems of not being able to meet the market demand, complex preparation system, long production cycle, etc., and achieve the effect of simple structure, simple production process and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

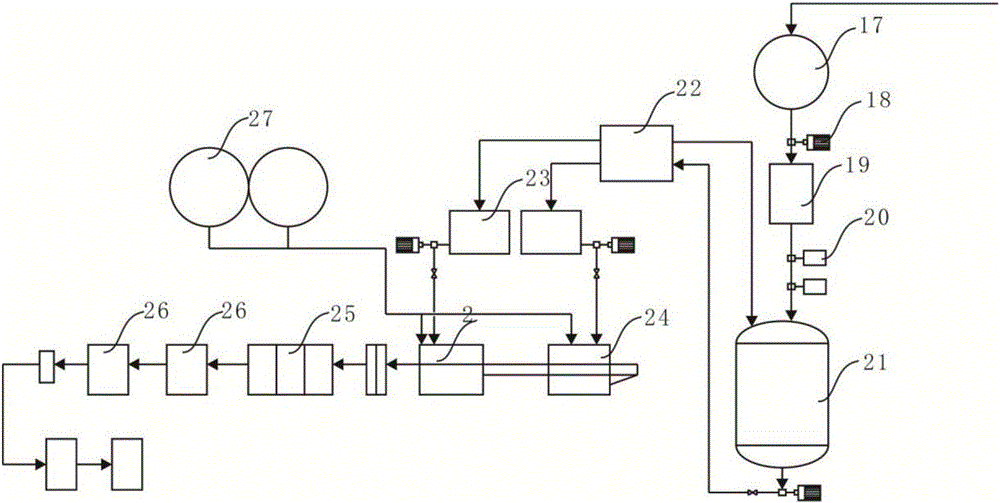

[0038] The mechanized production system of the calligraphy and painting paper of the present application, such as figure 1 As shown, it includes a pulping system, a papermaking system, a dewatering device and a drying device; wherein the pulping system includes a high-consistency pulper 17, a pulp storage tank 19, and a refiner 20 for crushing pulp boards. , the forecourt 21 for stirring the slurry to keep the concentration of the slurry uniform, the pulp mixing box 22 for adjusting the amount of slurry according to the thickness of the required paper, and the slurry water for adjusting the slurry to the required concentration by adding water Mixing pool23.

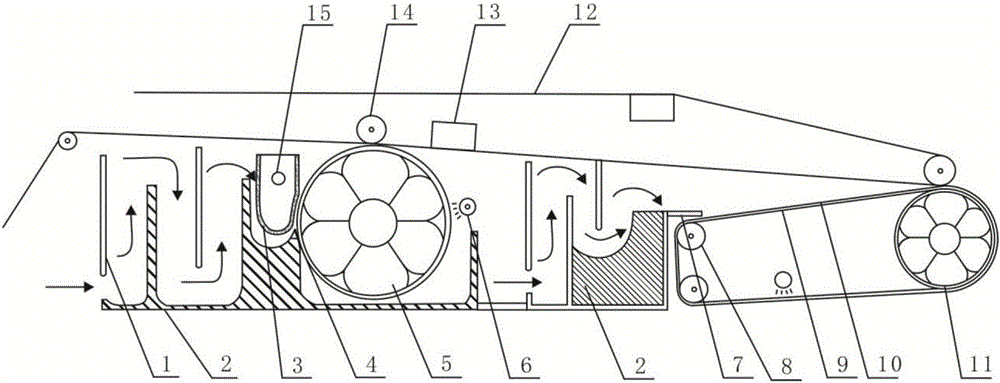

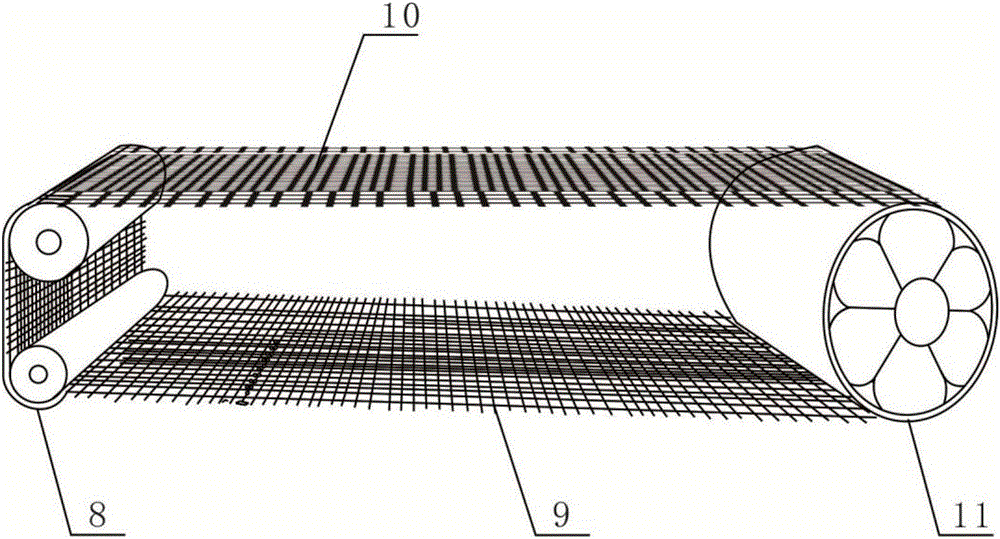

[0039] like figure 2 As shown, the papermaking system includes two net grooves 2, the first net cage 11, the second net cage 5, the forming plate 7 and the curtain pattern forming device 24; the curtain pattern forming device 24 comprises a bamboo curtain 10 and is enclosed within the bamboo curtain. The 14-purpose pla...

Embodiment 2

[0052] The mechanized production system of the calligraphy and painting paper of the present application, like embodiment 1, includes a pulping system, a papermaking system, a dehydration device and a drying device; the difference is that the papermaking system includes three grid tanks 3, the first net Cage 11, two second mesh cages 5, forming plate 7 and curtain pattern forming device; the drying device includes two drying cylinders 26.

[0053] Wherein, there are two mesh grooves 2 connected with the second mesh cage 5 respectively, respectively completing the sizing treatment process on the second mesh cage 5; another mesh groove 2 is connected with the forming plate 7 and the curtain pattern forming device in turn; wherein , The structural settings of the mesh tank 2, the second mesh cage 5 and the curtain pattern forming device are all the same as those in Example 1.

[0054] The process of adopting the system mechanized production of the application for painting and cal...

Embodiment 3

[0060] The mechanized production system of calligraphy and painting paper of the present application mainly comprises pulping system, papermaking system, dehydration device and drying device; The structure of pulping system is identical with embodiment 1; Image 6 As shown, the papermaking system includes a mesh table and a curtain pattern forming device, and the structure of the curtain pattern forming device is the same as that of Example 1; the curtain pattern forming device is enclosed within the mesh table 16, and 15 wires with a diameter of The first rubber roller 28 of 5cm and 4 vacuum boxes 13; The girth of bamboo screen 10 and plastic liner 9 is 16m; Because bamboo screen 10 is longer, therefore, the first rubber roller 28 plays the effect of transmission and dehydration.

[0061] The drying device includes a three-stage oven and two drying cylinders connected in sequence.

[0062] The process of adopting the system mechanized production of the application for paintin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com